Smashing-feeding device for single crystal furnace

A technology of feeding device and single crystal furnace, which is applied in the direction of single crystal growth, single crystal growth, post-processing equipment, etc., and can solve the problems that cannot be applied to the production process of single crystal silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

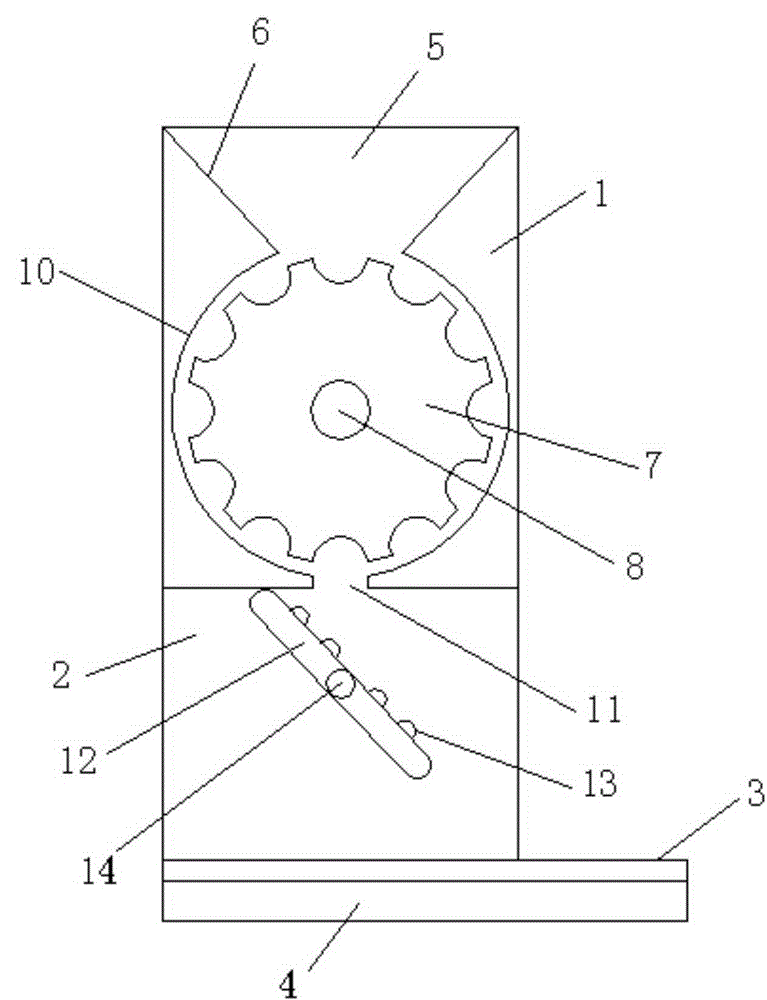

[0012] like figure 1 The shown crushing and feeding device for single crystal furnaces includes a crushing box 1, a storage box 2 and a conveying mechanism, the crushing box 1 is connected to the top of the storage box 2, and the The conveying mechanism is arranged at the bottom of the material storage box 2, and the pulverizing box 1 is provided with a pulverizing wheel 7, and the pulverizing wheel 7 is set on the first rotating shaft 8, and the first rotating shaft 8 is connected with the first motor, and the outer side of the crushing wheel 7 is provided with an arc-shaped baffle 10, and the upper end of the arc-shaped baffle 10 is connected with an oblique deflector 6, and the crushing above the deflector 6 The box body 1 is provided with a feed inlet 5, and the pulverization box body 1 below the arc baffle 10 is provided with a first discharge port 11, and the pulverization box body 1 is connected to the storage tank through the first discharge port 11. Material box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com