A method for controlling washing machine flocculation treatment water through turbidity measurement and washing machine

A measurement control and washing machine technology, applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problem that the process of flocculation treatment water cannot be carried out normally, the floc particles are small and cannot be effectively layered, and the filter screen of the filter container is blocked, etc. problems, to achieve accurate flocculant dosage, avoid poor flocculation effect or even failure, and prevent secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

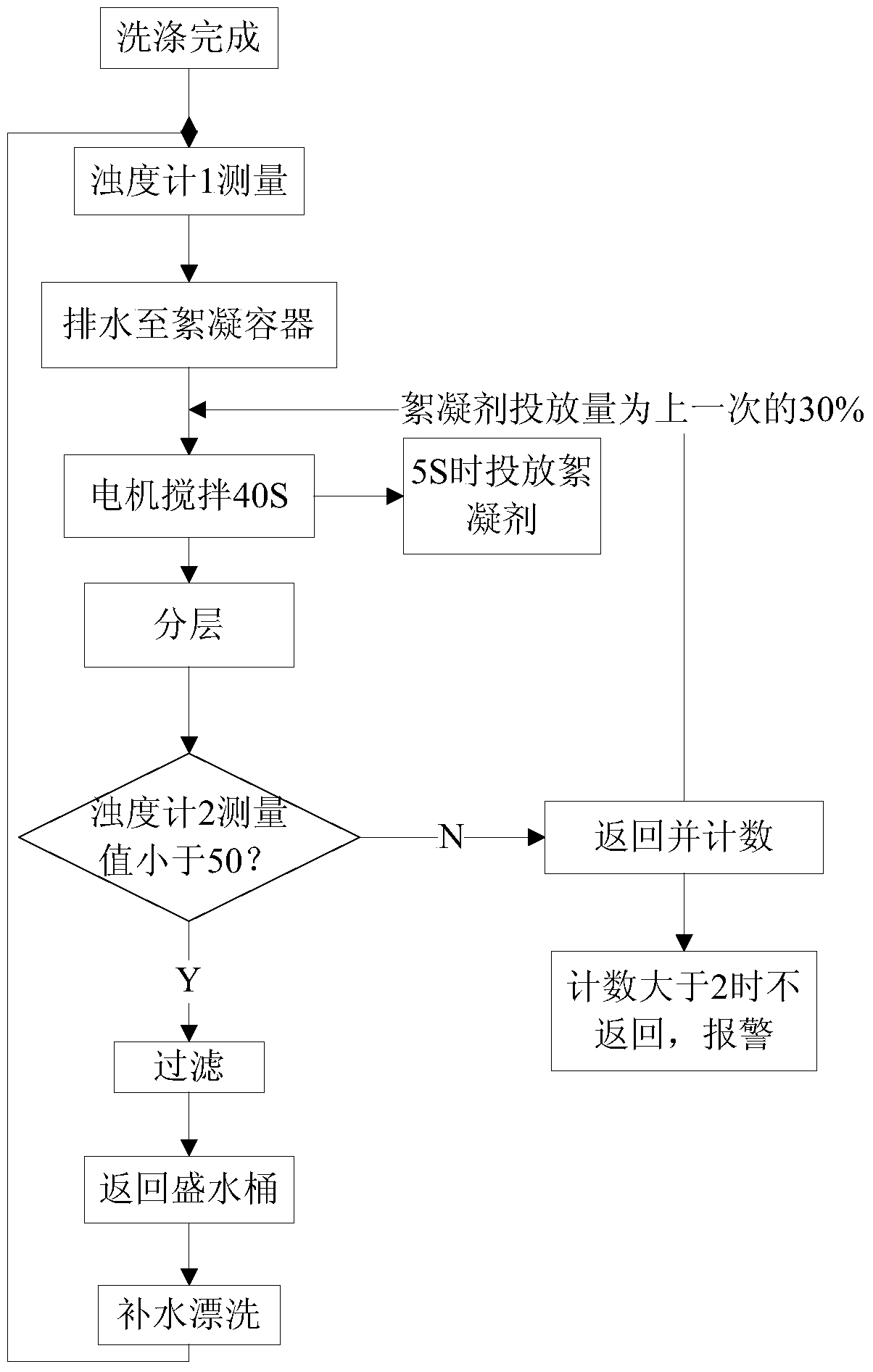

[0040] Such as figure 1 As shown, the washing is completed, and the measured turbidity value of the washing water is recorded as N1. The turbidity value N1 can be detected when it is in the bucket before it is discharged into the flocculation container, or it can be discharged into the flocculation container before the flocculant is put in. For detection, this embodiment uses the washing water to detect the turbidity value when it is not discharged into the flocculation container and is still in the water bucket. In this way, if the detected turbidity value is high, it can be directly discharged when it is not suitable for flocculation, and the flocculation treatment water is not used; omitted The step of entering the flocculation container is eliminated, which not only saves time but also prevents the flocculation container from being polluted by washing water and needs to be cleaned.

[0041]According to the detected turbidity value N1, determine the initial flocculant dosag...

Embodiment 2

[0045] This embodiment makes improvements for the color fading of the clothes: when the clothes are fading, the detected turbidity value is high, and the main control board can no longer judge whether the clothes are rinsed clean, so it cannot make a correct judgment. Therefore, the turbidity value before and after the flocculation treatment can be compared. When the difference between the turbidity value before and after the treatment is less than 20, it is considered that the turbidity value is caused by color fading, and the clothes have been rinsed and entered the dehydration process.

Embodiment 3

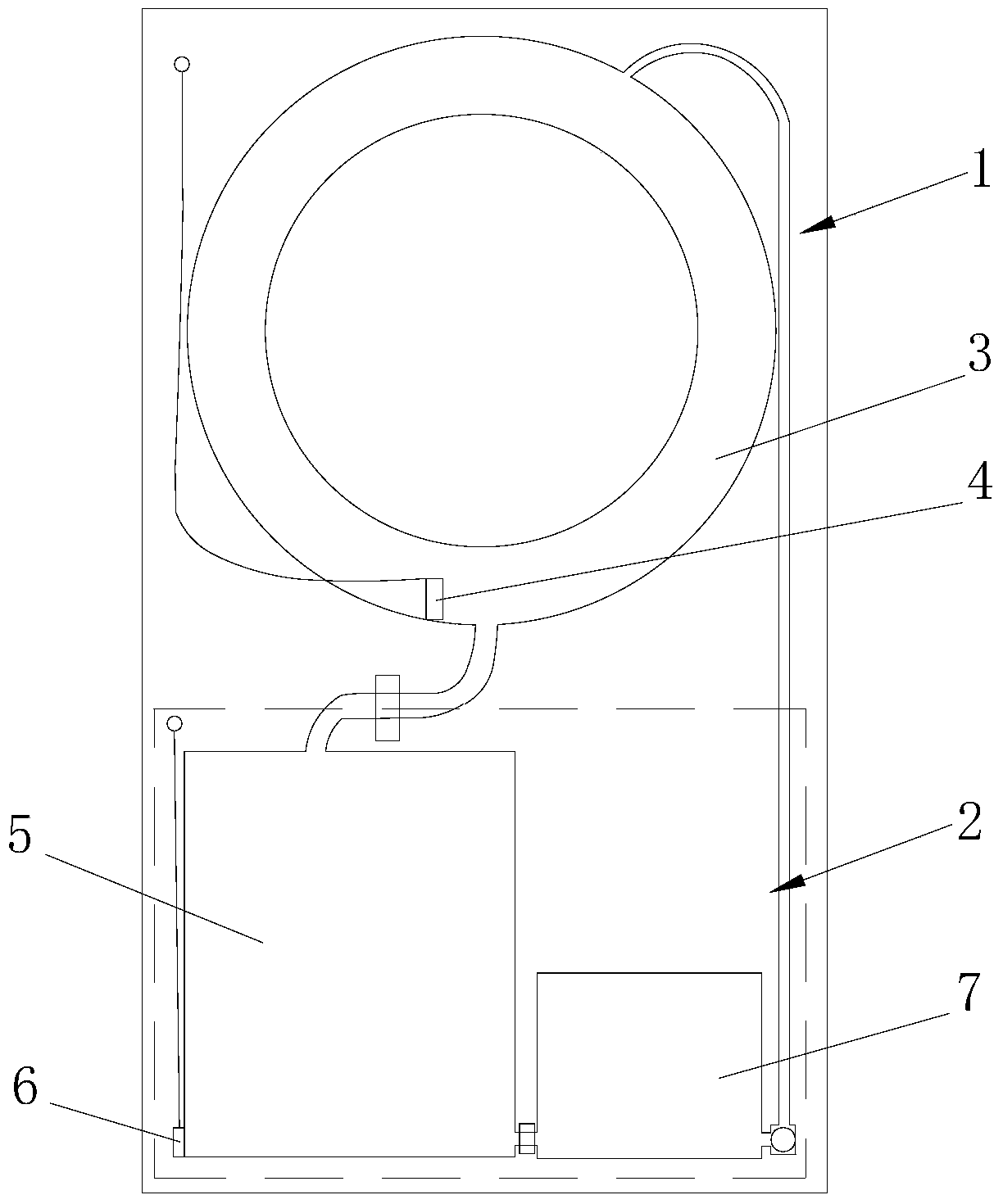

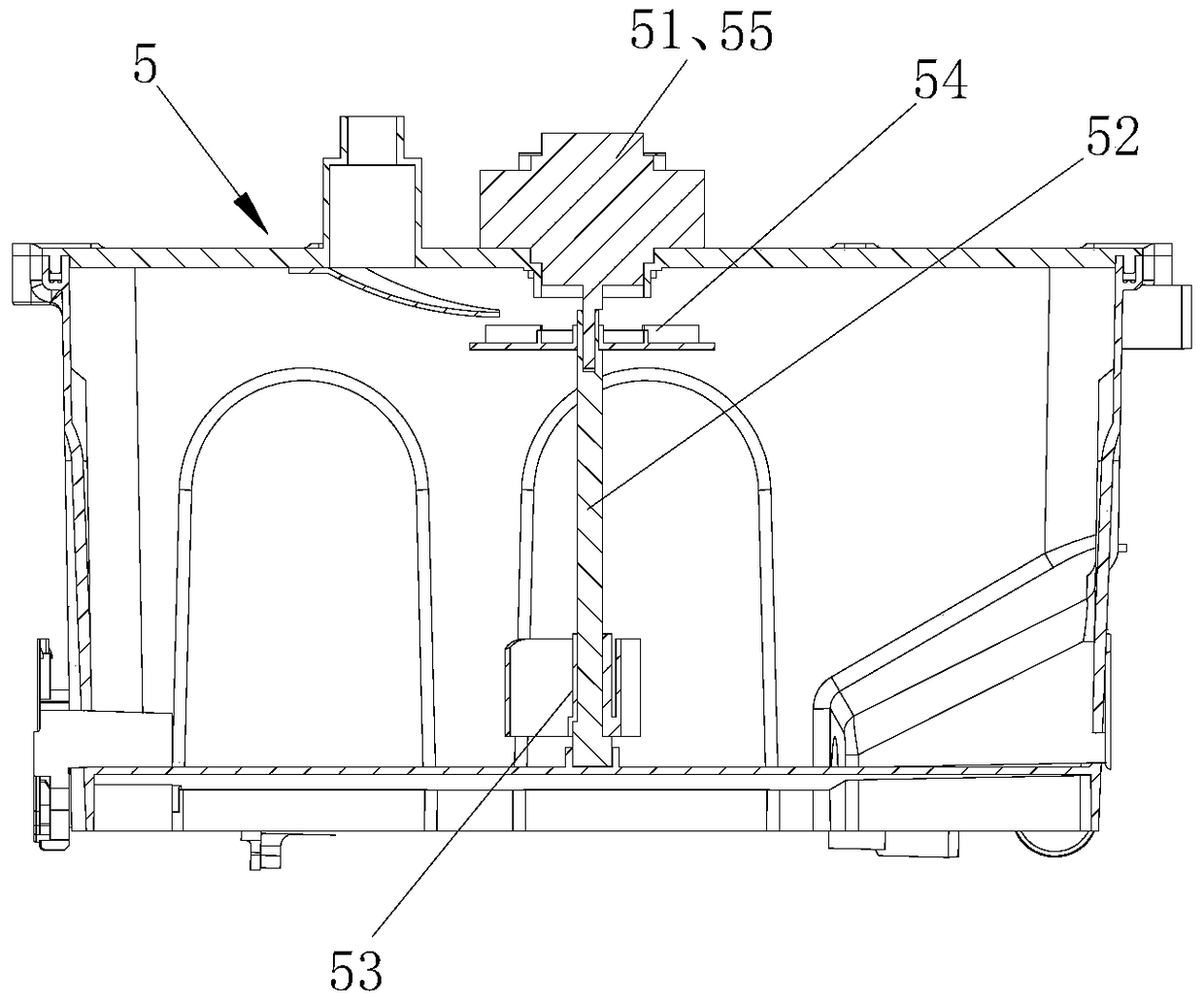

[0047] Such as figure 2 and image 3 As shown, the washing machine of the present invention includes a washing machine body 1 and a water circulation treatment system 2. The washing machine body 1 needs to have various parts of an ordinary washing machine, including a washing bucket 3, a main control board for controlling washing, and an automatic detergent injection device. (not shown in the figure), the tub 3 is provided with a tub turbidity detection device 4, which has a weighing or similar function to determine the amount of laundry, and a water level sensor or similar function to determine the amount of laundry water. The water circulation treatment system 2 includes a flocculation container 5 for flocculation treatment of laundry water with a flocculant, and the flocculation container 5 is provided with a flocculation turbidity detection device 6 . Further, it may also include a filter container 7 for filtering the flocculation treatment water, as well as structures s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com