A rapid construction method for deep overburden grouting

A technology with deep covering layer and construction method, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of high fluidity of casing slurry, inability to achieve rapid deviation correction, and easy deflection of casing valve pipes. Achieve the effect of benefiting construction progress and quality, improving construction progress and quality, and ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

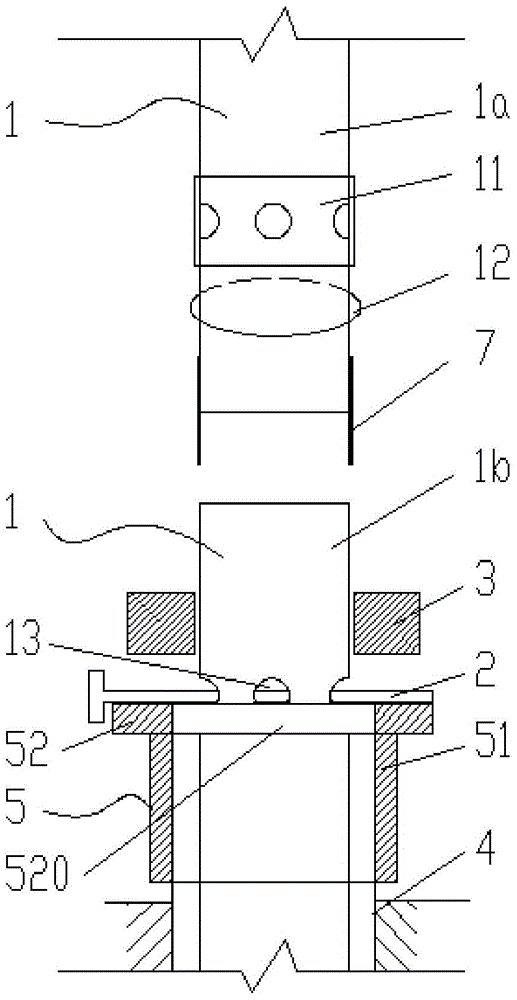

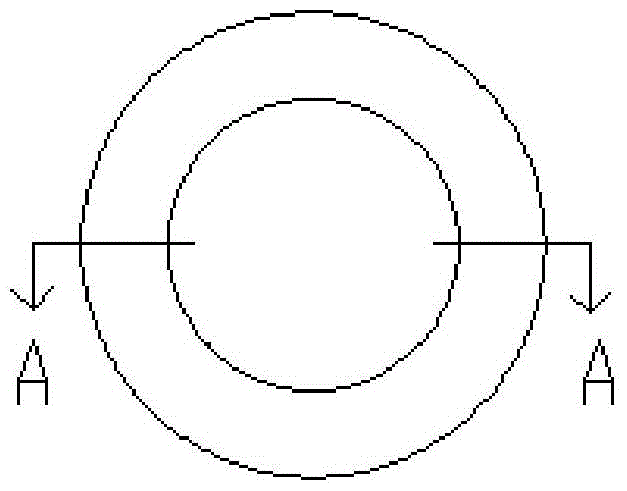

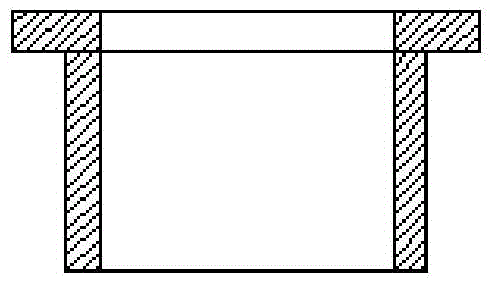

[0032] The present invention provides a rapid construction method for grouting in deep overburden, which comprises the following steps: by using at least two kinds of drilling tools to alternately carry out the drill operation of follow-up pipe once, forming a working hole surrounded by lowered follow-up pipes, so as to Use the operation hole to grout the deep overburden; install the orifice locator 5 on the port of the heel pipe at the opening of the operation hole to locate the multi-section sleeve valve pipe 1 set in the operation hole to the operation hole Center; use the orifice locator 5 to set each section of the sleeve valve tube in turn parallel to the heel tube and set it into the working hole; pour the casing into the annular gap between the multi-section sleeve valve tube 1 and the heel tube 4 Slurry until the casing slurry overflows from the orifice; after the poured casing slurry has solidified for a period of time, quickly take out the follower pipe from the bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com