Pumping unit with auxiliary balance device

A technology of auxiliary balance and pumping unit, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of difficulty in disassembly, failure to conform to the structure of the pumping unit, and difficulty in obtaining dynamic balance, etc., to achieve convenient disassembly Maintenance, reliable connection, and reduced power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

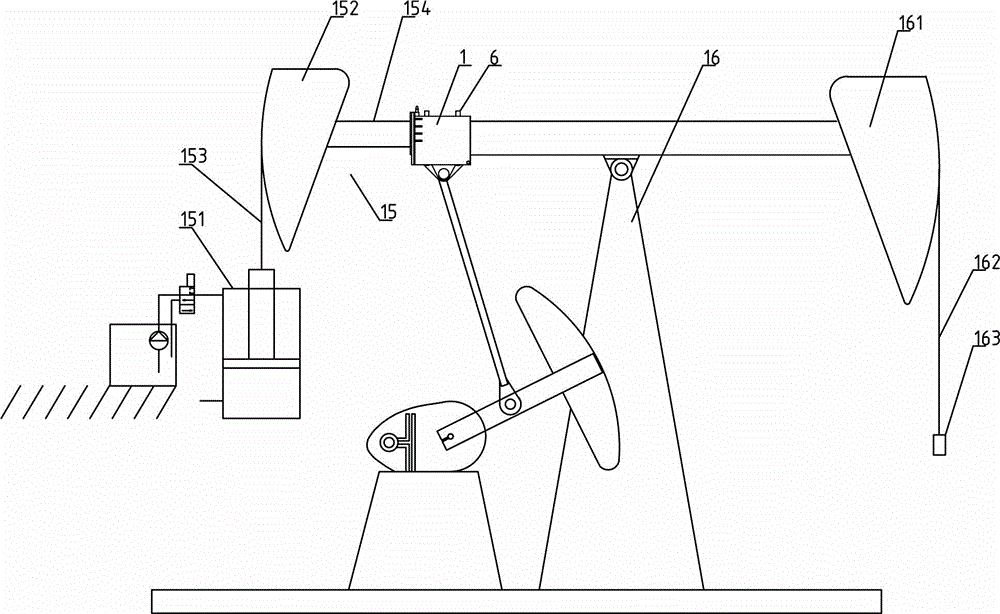

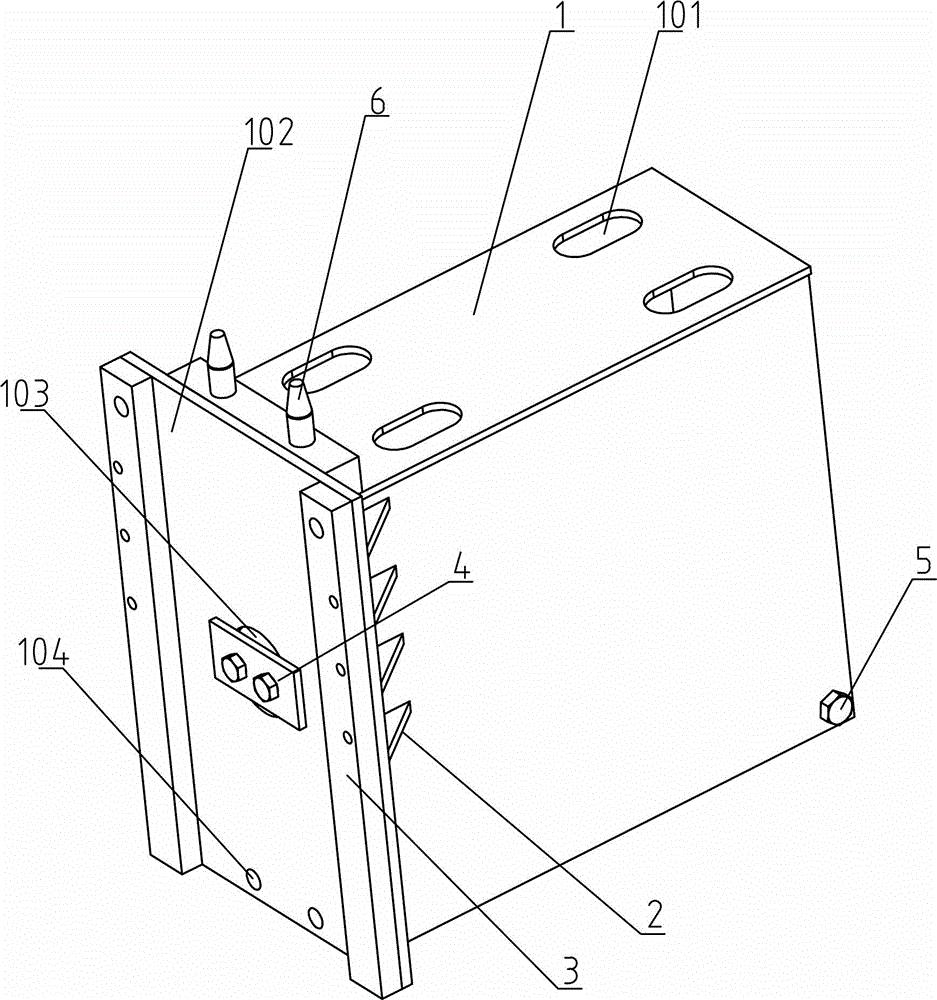

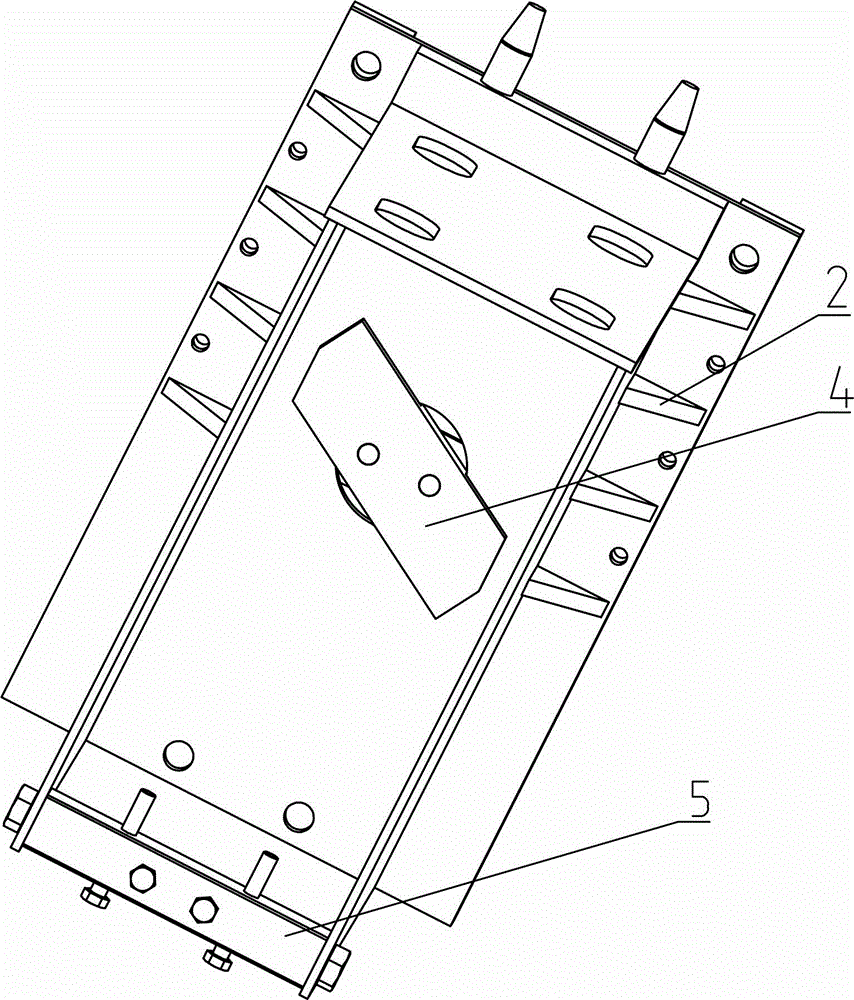

[0035] like figure 1 , 9 Among them, a pumping unit with an auxiliary balancing device includes a pumping unit 16, and the auxiliary balancing device 15 is connected with the beam tail 14 of the pumping unit 16;

[0036] The structure of the auxiliary balance device 15 is that the rear donkey head 152 is fixedly connected with one end of the connecting rod 154, the other end of the connecting rod 154 is connected with the tail 14 of the beam, and the rear donkey head 152 is connected with the hydraulic cylinder type counterweight 151 through the suspension rope 153 . With this structure, when the hydraulic cylinder counterweight 151 rises to the highest point, hydraulic oil is injected into the hydraulic cylinder counterweight 151, and the hydraulic oil is discharged during the descent process, thereby simulating the crude oil pumped in the sucker rod 163 Weight, realize the dynamic balance of the whole beam, and greatly reduce the variation range of the motor power output. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com