Fluid pressure control device

一种控制装置、液压的技术,应用在阀装置、流体压力致动装置、阀的操作/释放装置等方向,能够解决制造成本升高、不利等问题,达到减少组装工序、节省成本、制造容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, an embodiment of the present invention will be described based on one embodiment of the present invention shown in the drawings.

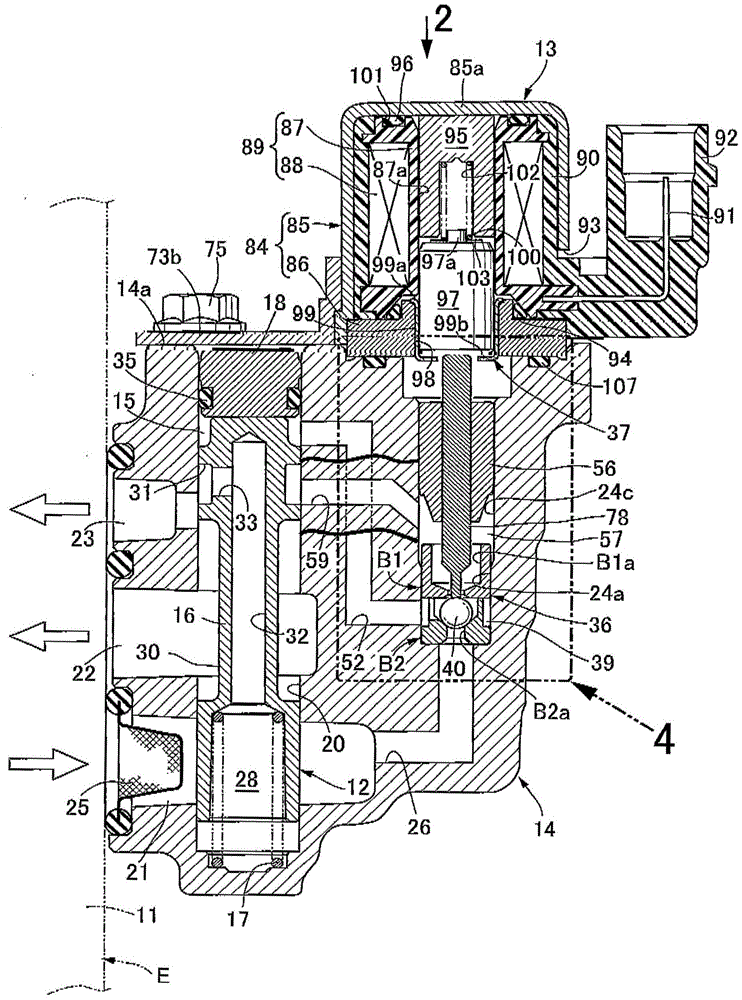

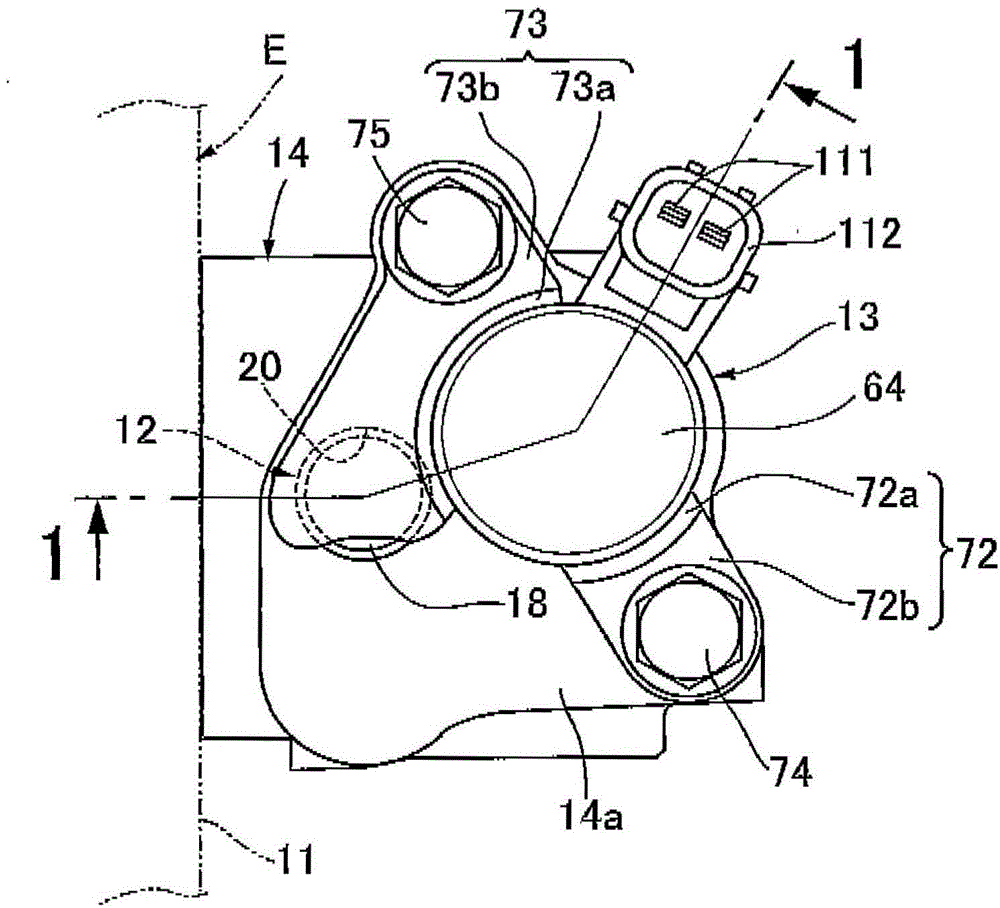

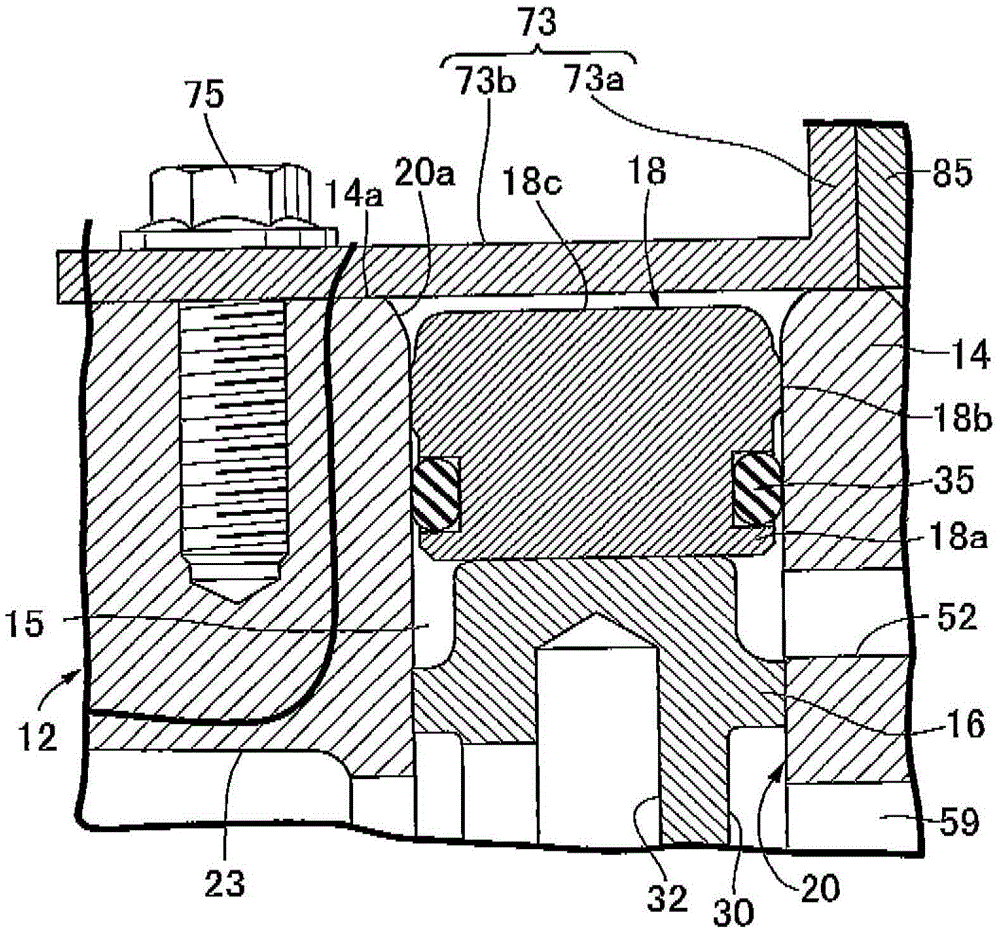

[0052] First, in figure 1 and figure 2 Among them, the hydraulic pressure control device is, for example, a device that switches the hydraulic pressure to high and low and acts on the valve train in order to change the operating characteristics of the valve train in the engine E mounted on the vehicle. It includes: a slide valve 12, which It has a valve body 14 fastened to the engine main body 11 of the engine E; and an electromagnetic three-way valve 13 that connects a hydraulic pressure source such as a hydraulic pump built in the engine main body 11 between the pilot chamber 15 provided in the spool valve 12 . Installed on the valve body 14 in a manner between. As will be described later, the electromagnetic three-way valve 13 is detachably attached to the valve body 14 by fastening the pair of mounting brackets 72 and 73 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com