Rotary table dynamic angular position error measurement precision improving device and rotary table dynamic angular position error measurement correcting method

A technology of error measurement and dynamic angle, which is applied in the direction of measuring devices, instruments, Sagnac effect gyroscopes, etc., can solve the problems of high data update rate, limited precision, and inability to measure the dynamic characteristics of angle rotation, so as to eliminate the dynamic angle The effect of position positioning error and best practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

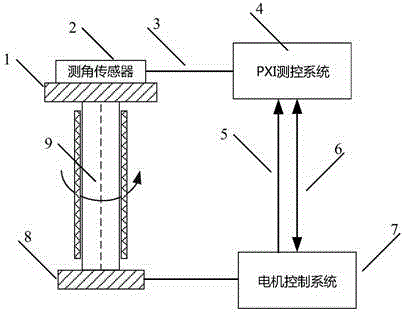

[0024] see figure 1 , which is the structure and components of the dynamic angular position positioning error measurement device targeted by the present invention.

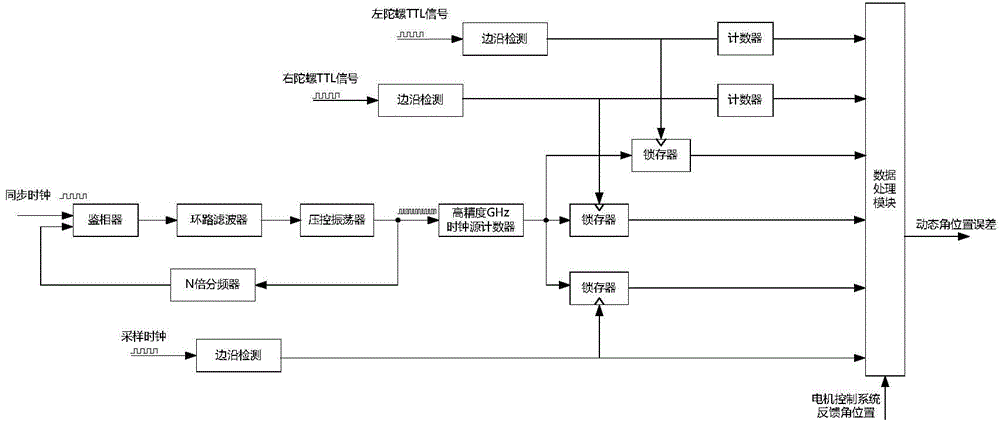

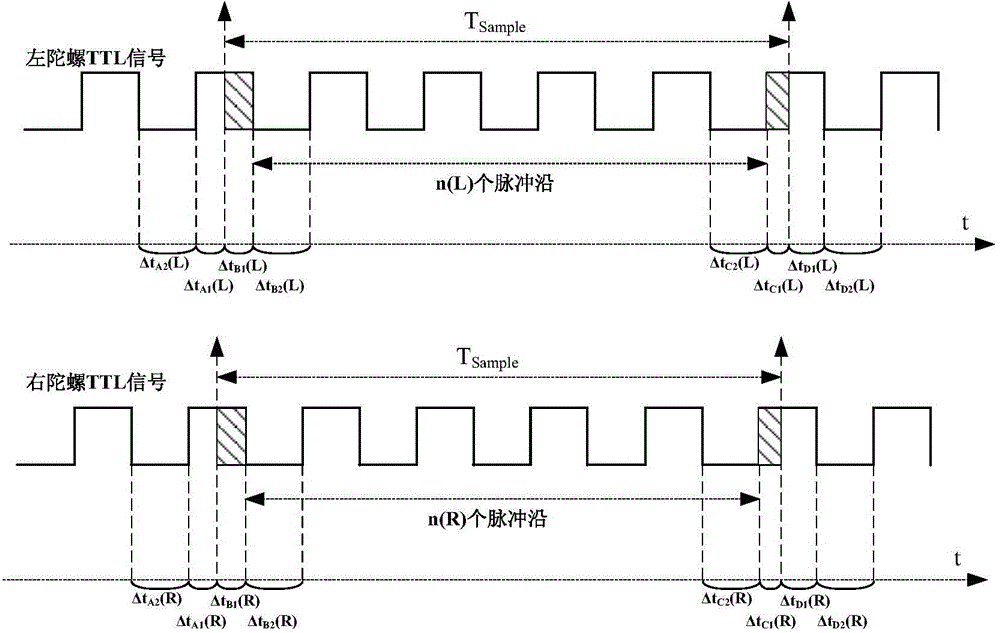

[0025] The dynamic angular position positioning error measuring device of the present invention comprises an angle measuring sensor, a PXI measurement and control system, a motor control system, and a servo motor. Among them, the angle measuring sensor is composed of a spatial four-frequency differential laser gyroscope and its control circuit. The turntable to be tested is connected to the servo motor, and the measuring end is provided with a transition board 1, the angle sensor is installed on the transition board, and connected to the PXI measurement and control system through a flexible cable, which is connected to the motor control system 7 through a signal channel and a data channel , whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com