Adhesive force measurement method and device

A measurement method and adhesion technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve problems such as difficult adhesion, failure to reflect adhesion, complex structure, etc., and achieve the effect of simple operation, reasonable structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

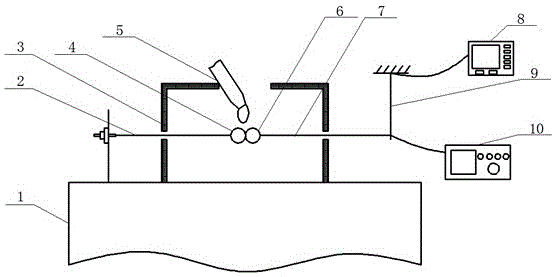

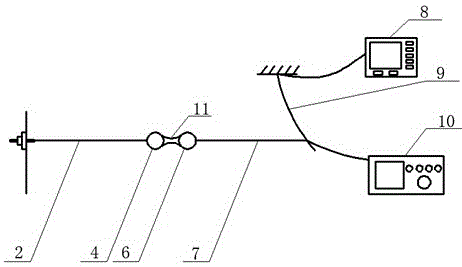

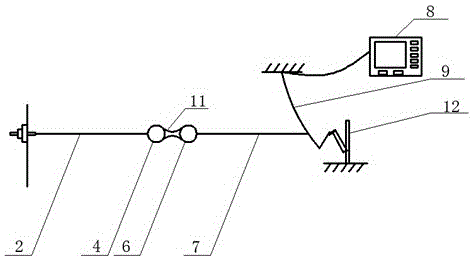

[0015] A method for measuring adhesion force, which includes the following steps: select two highly elastic steel wires, one steel wire is fixed on a workbench, and one end of the other steel wire is fixed on a piezoelectric micro-cantilever beam sensor, and the two steel wires are kept on the On the same straight line, one particle is bonded to the close ends of the two steel wires; a liquid is added to the contact point of the two particles; the piezoelectric micro-cantilever sensor is quantitatively bent by a millivolt generator or a micromanipulator; The piezoelectric micro-cantilever sensor drives the connected steel wire and the particles attached to it to move together, the two particles gradually separate, and the liquid between the particles forms a liquid bridge; the voltage output by the piezoelectric micro-cantilever sensor is collected and recorded by an oscilloscope , through the calibration of the piezoelectric micro-cantilever sensor, the tensile force of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com