Internet of things-based factory source of danger real-time monitoring control system and control method

A real-time monitoring and control system technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve problems such as easy accidents, easy failures, and control system failures, so as to avoid personal injury losses and potential safety hazards , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

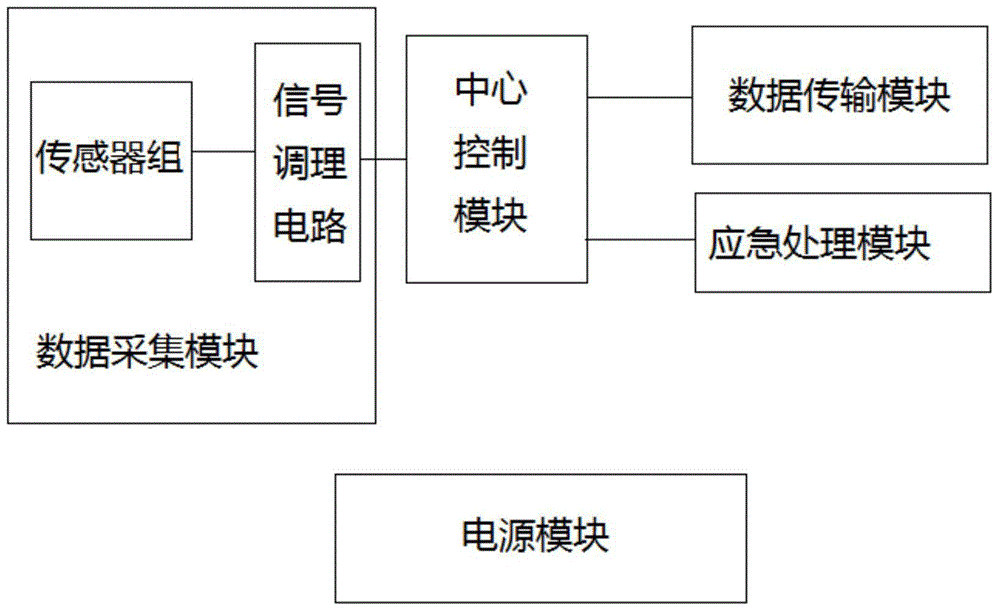

Image

Examples

Embodiment 1

[0035] Preferably, in this embodiment, the sensor group shown includes a smoke sensor, a temperature sensor, and a dust sensor respectively connected to the signal conditioning circuit.

[0036] In order to achieve emergency treatment, in this embodiment, preferably, the emergency treatment modules are respectively arranged on the side of the smoke sensor, temperature sensor, and dust sensor, and are used to activate the smoke sensor, temperature sensor, and dust sensor. Surrounding fire and ventilation equipment.

[0037] Further preferably, a power-down detection circuit is provided on the central control module.

[0038] Preferably, in order to realize timely alarm, in this embodiment, an alarm circuit is provided on the central control module.

[0039] As a preference, in this embodiment. Described ZigBee module is CC2530 chip; Described central control module is AT89S52 single-chip microcomputer; Described central control module is provided with storage unit, and descri...

Embodiment 2

[0041] On the basis of Embodiment 1, this embodiment discloses a real-time monitoring and control system method for factory hazard sources based on the Internet of Things, including the following steps:

[0042] S1: Set the reference range: set the reference safe smoke concentration, temperature, and dust concentration values in the central control module;

[0043] S2: Detect smoke concentration, temperature information, and dust concentration information in the factory environment and send them to the central control module for comparison with the reference range;

[0044] S3: When the real-time detection value reaches the reference range value, send data information to the host computer through the Zigbee module, the host computer sends a control signal to the central control module through the Zigbee module, and the central control module sends drive information to the device through the industrial control bus module. The equipment power supply, the central control module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com