Spray apparatus used on building site and control method thereof

A spray device, construction site technology, applied in non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of low automation integration, few analog signals, low intelligence, etc. Electric heat tracing function, the effect of protecting equipment safety and facilitating emergency operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

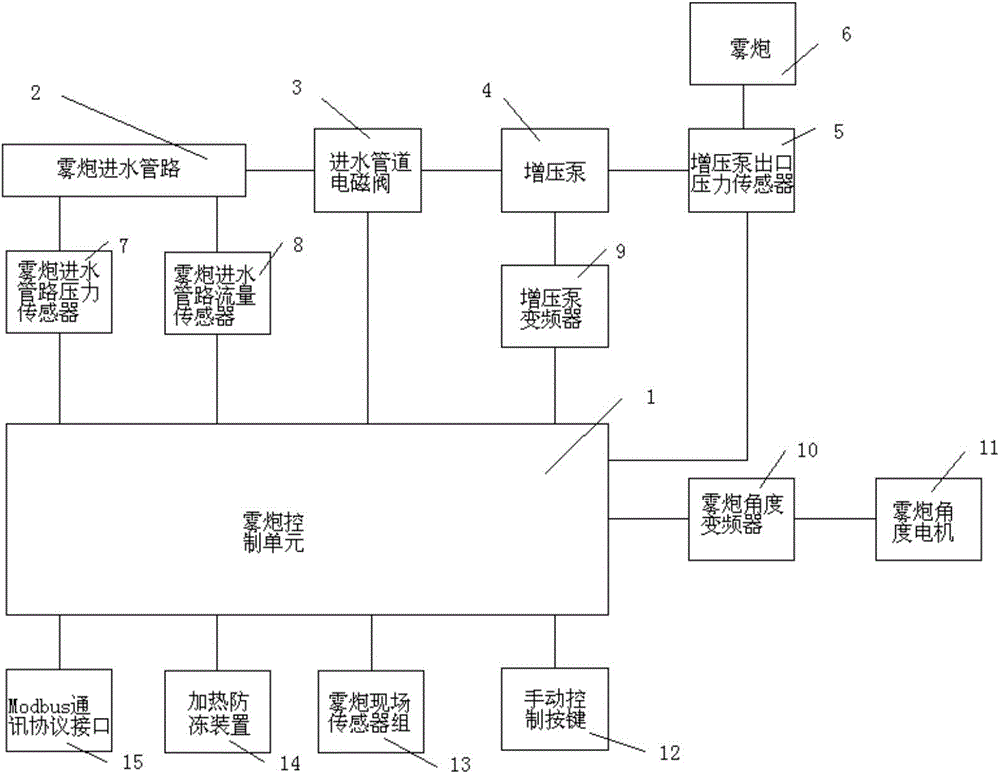

[0049] A spraying device for a construction site, powered by a power supply, including a fog cannon water inlet pipeline 2, a fog cannon 6, a fog cannon control unit 1, a fog cannon angle motor 11, a fog cannon angle frequency converter 10, and a fog cannon water inlet pipeline pressure sensor 7. Fog cannon water inlet pipeline flow sensor 8, booster pump 4, booster pump frequency converter 9, booster pump outlet pressure sensor 5, water inlet pipeline solenoid valve 3 and manual control button 12, the fog cannon control unit passes The fog cannon angle converter is electrically connected with the fog cannon angle motor, the fog cannon water inlet pipeline is connected with the fog cannon through the booster pump, the fog cannon water inlet pipeline pressure sensor, the water inlet pipeline solenoid valve and the fog cannon The flow sensors of the water inlet pipeline are all arranged on the water inlet pipeline of the fog cannon, the pressure sensor of the water inlet pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com