Cable-type flow-guided lithium-ion flow battery reactor

A technology of battery reactor and flow battery, which is applied in the direction of fuel cell additives, regenerative fuel cells, etc., can solve the problems of crushing the sandwich composite structure layer, warping deformation, uneven battery current, etc., to reduce processing difficulty and production cost, reduce battery polarization internal resistance, and reduce the effect of accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

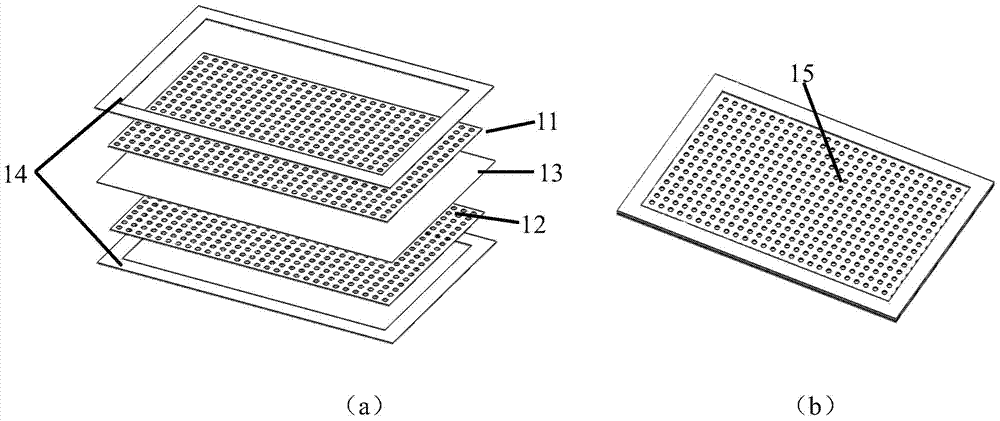

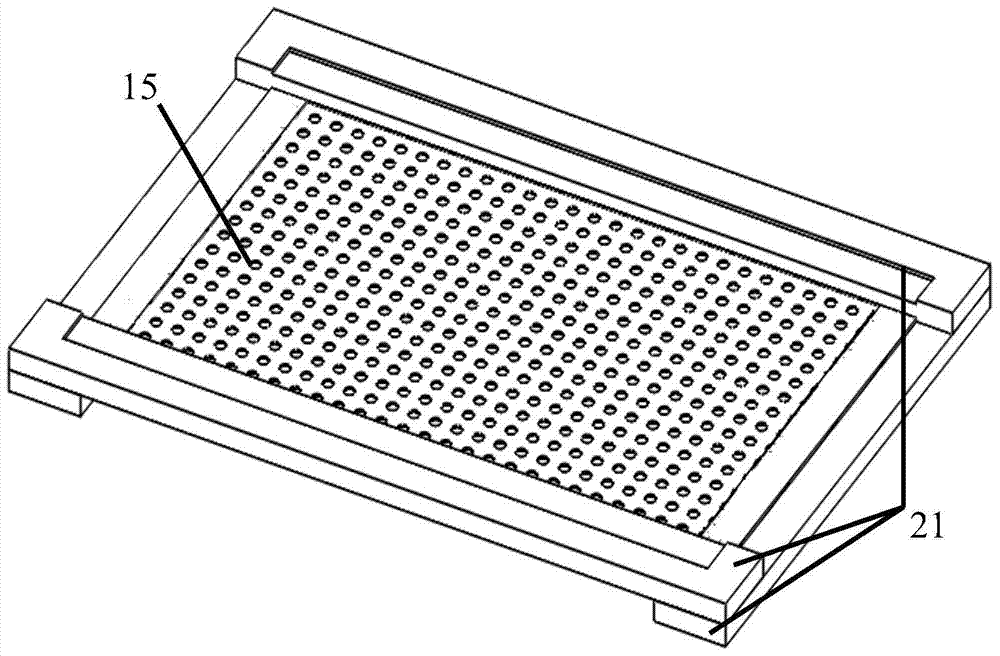

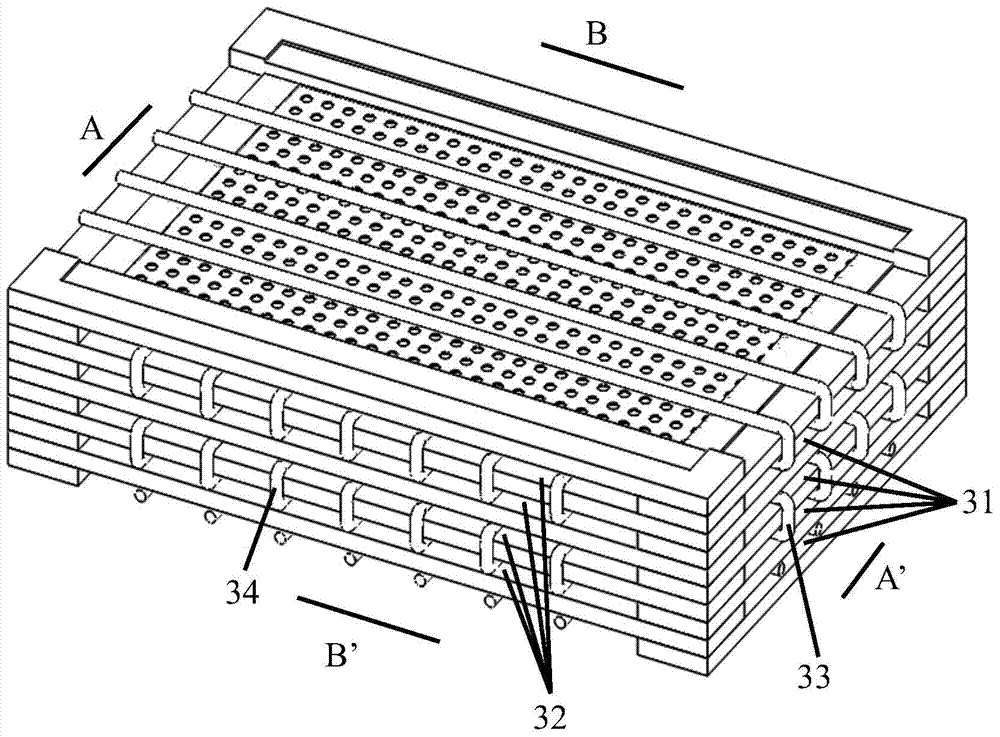

[0035] like figure 1 As shown, the sandwich composite structure layer 15 includes a porous positive electrode current collecting layer 11, a porous negative electrode current collecting layer 12, an insulating layer 13 and an insulating frame 14 around it, and the porous positive electrode current collecting layer 11 and the porous negative electrode current collecting layer 12 are respectively placed in the isolation Both sides of the layer 13 are in close contact with the isolation layer 13, and the edges of the porous positive electrode current collecting layer 11 and the porous negative electrode current collecting layer 12 are combined with the insulating frame 14 by bonding or hot pressing. figure 1 (a) is a schematic diagram of the assembly of the sandwich composite structure layer, figure 1 (b) is a schematic diagram of the overall stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com