Embedded electromagnetic speed regulation coal cutter traction system based on fuzzy control

An electromagnetic speed regulation and fuzzy control technology, which is applied in control systems, electric controllers, AC motor control, etc., can solve the problems of low control accuracy, waste of hardware and software, and low level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

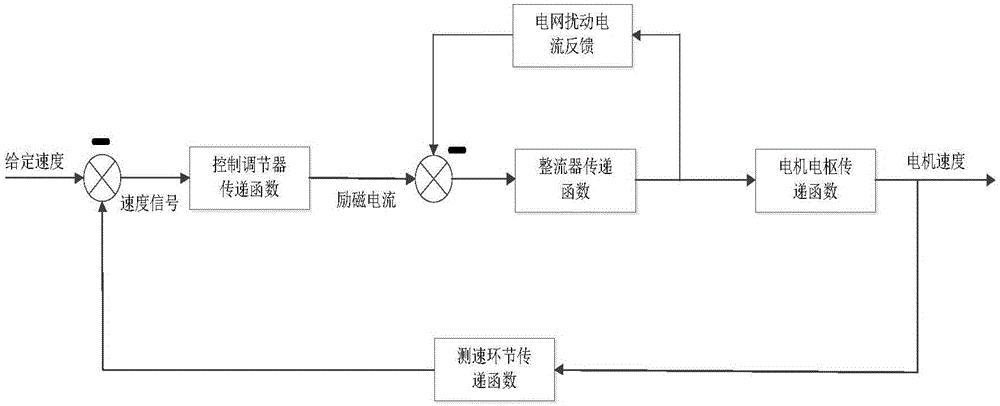

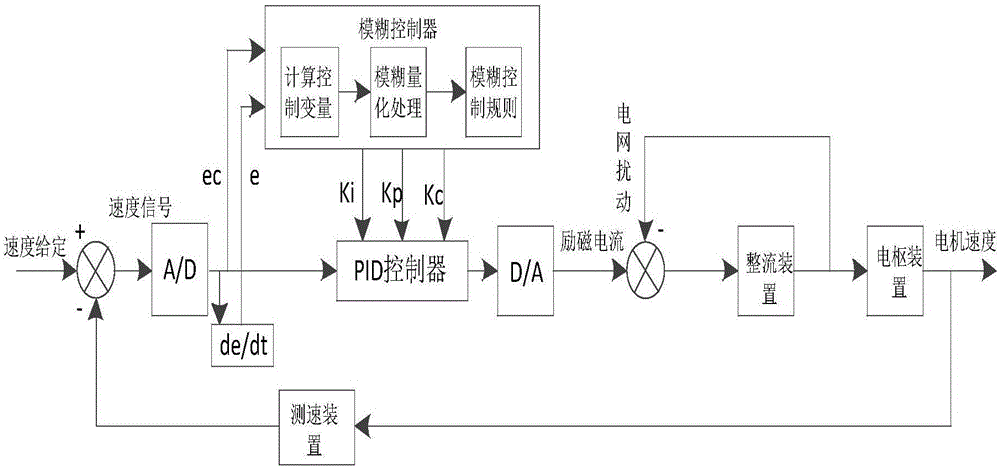

[0032] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention, so they only show the configurations related to the present invention.

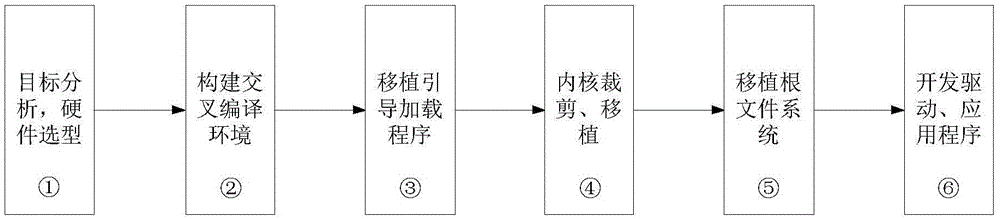

[0033] Such as Image 6 The overall block diagram of the system hardware is shown, and the system is divided into two parts: the management host and the underlying control module. As the control core of the system, the management host sends instructions to the underlying control module to complete the control of the shearer. The core idea of the control is speed and current double closed-loop fuzzy PID speed regulation. The management host is equipped with an ARM-based Linux operating system, and the embedded core chip is AT91SAM9260 from AT Company. According to the target requirements of the electromagnetic speed-adjustable shearer, an RS232 serial port and SD car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com