Defrosting glass, defrosting lamp and automobile with defrosting glass and defrosting lamp

A glass and frost lamp technology, which is applied in the directions of motor vehicles, road vehicles, lighting devices, etc., can solve the problems of low durability, the conductivity needs to be further improved, and the metal layer is easy to oxidize, so as to improve the mechanical properties, improve the Service life, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

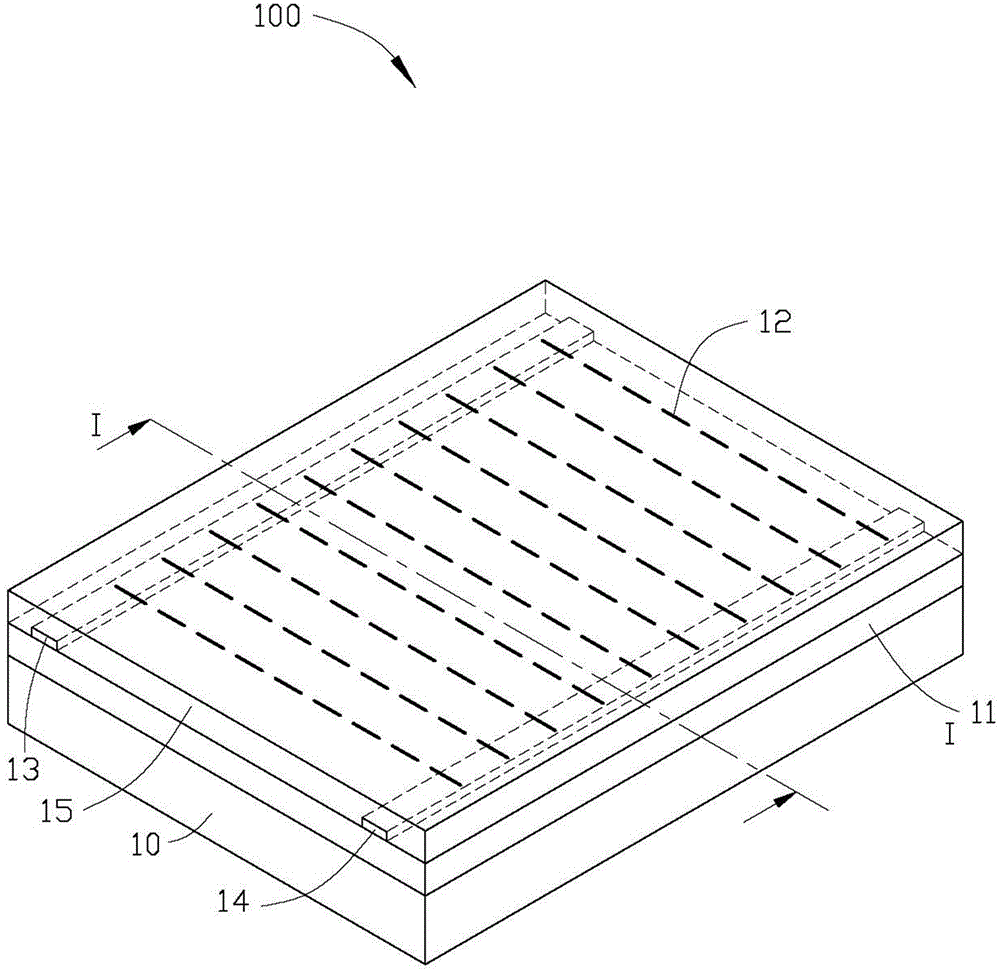

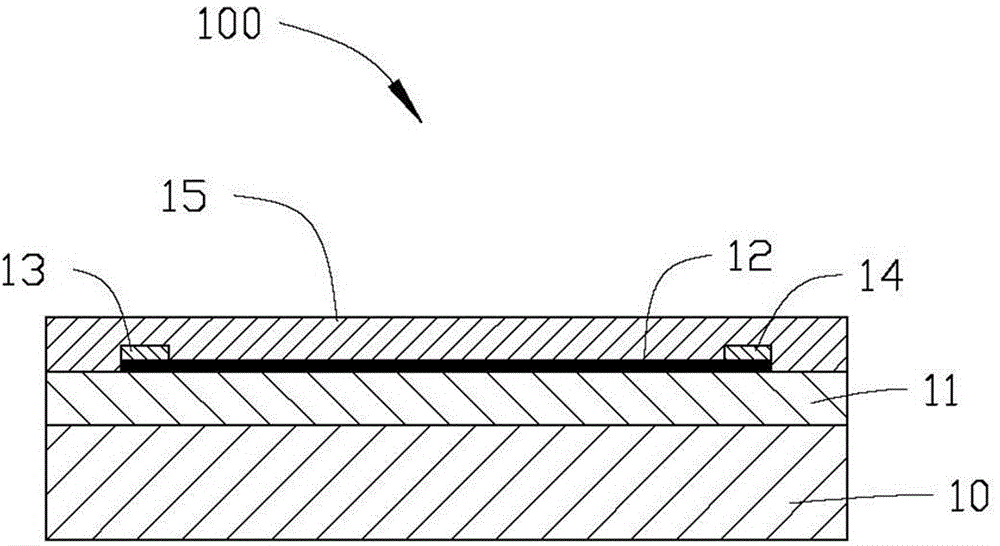

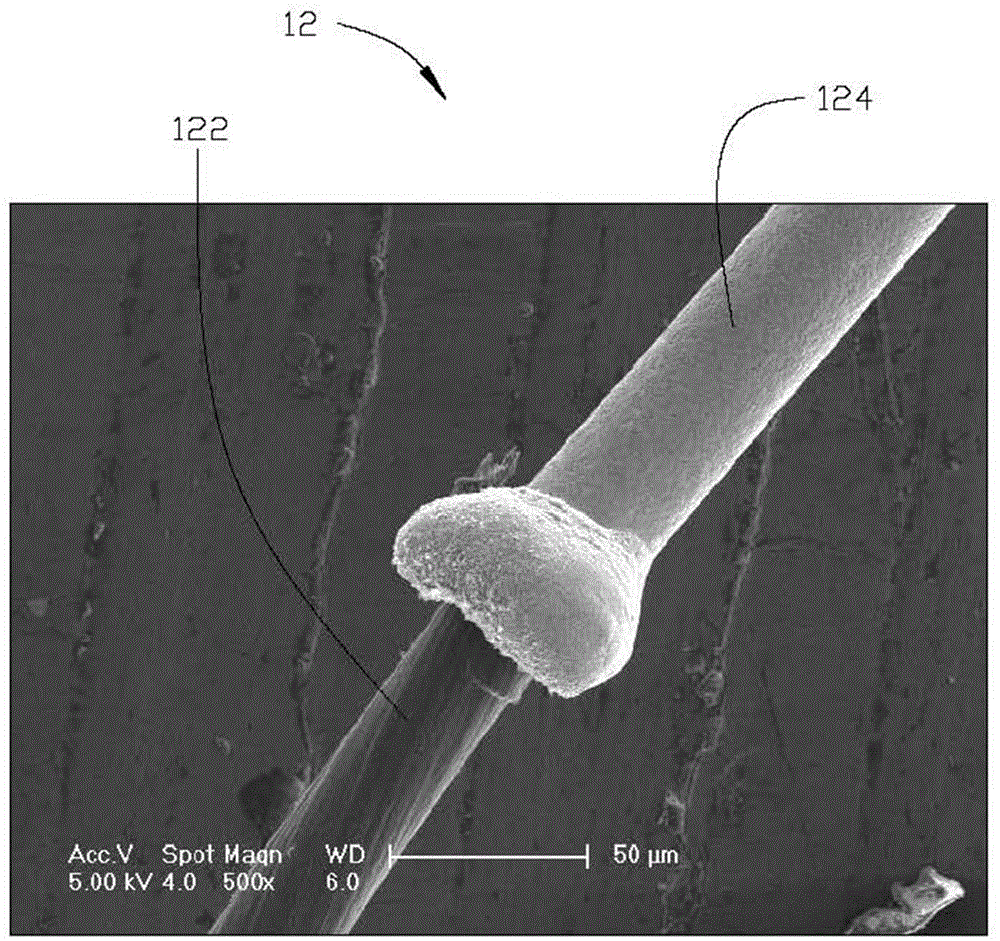

[0026] See figure 1 and figure 2 , The embodiment of the present invention provides a defrost glass 100, the defrost glass 100 includes a glass substrate 10, a binder layer 11, a plurality of carbon nanotube composite wires 12, a first electrode 13, a second electrode 14 and a polymer protective layer 15. The adhesive layer 11 is disposed on the surface of the glass substrate 10. The plurality of carbon nanotube composite wires 12 are arranged in parallel and spaced apart, and are fixed to the surface of the glass substrate 10 by the adhesive 11. The first electrode 13 and the second electrode 14 are respectively arranged at both ends of the carbon nanotube composite wire 12, and are in electrical contact with the carbon nanotube composite wire 12, for feeding the carbon nanotube composite wire 12 A voltage is applied to cause current to flow in the carbon nanotube composite wire 12. The polymer protective layer 15 covers the surfaces of the first electrode 13, the second el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com