Polyvinyl alcohol and ethylene vinyl alcohol copolymer barrier coatings

A technology of vinyl alcohol copolymer and polyvinyl alcohol, which is applied in the direction of coating, etc., and can solve the problems of blocking coatings and non-disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

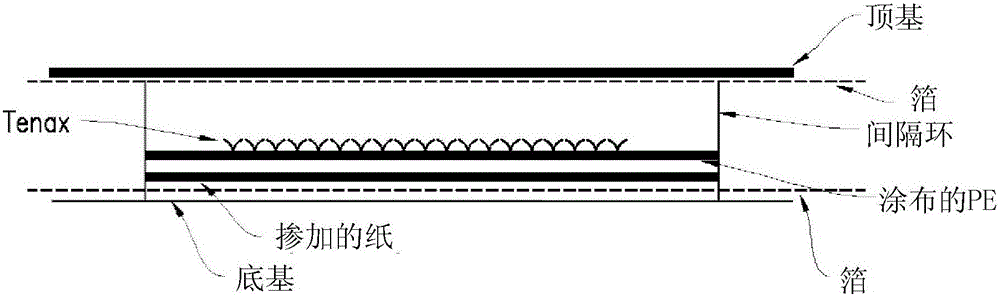

Image

Examples

Embodiment 1

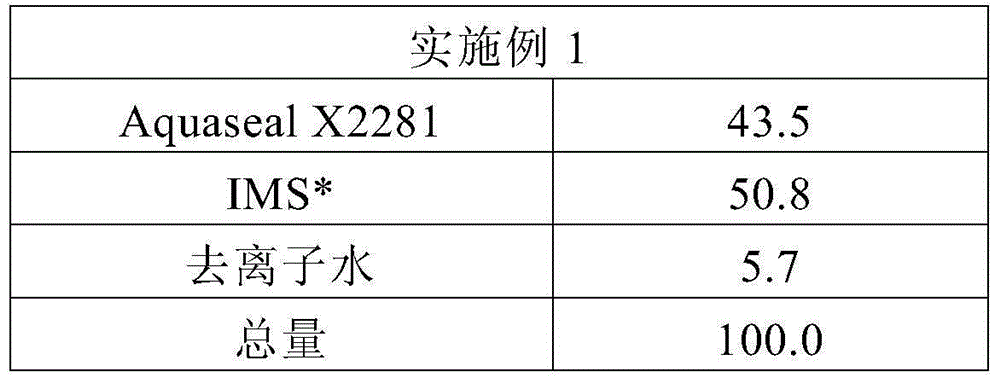

[0079] X2281 is a solution of polyvinyl alcohol in water supplied by Paramelt B.V. Netherlands. The polymer solution was supplied with a non-volatile content of about 20-22%. In the laboratory, with a mixture of industrial methylated spirits (IMS* also sold as TSDA) and water in a vortex mixer with gentle agitation on the vortex X2281 was further diluted (see Table 1).

[0080] Table 1 - Composition of Example 1

[0081]

[0082] IMS* = ethanol denatured with 2.2% ethyl acetate and 0.1% 2-propanol

[0083] As shown in Table 2, the following results were obtained.

[0084] Table 2 - Properties of Example 1

[0085]

Embodiment 2A、2B and 2C

[0087] 2-97 is a polyvinyl alcohol resin supplied by Kuraray Specialties Europe. It has a molecular weight of approximately 5000 Daltons. The viscosity specified by Kuraray as a 4% aqueous solution at 20°C is 2.2-2.3 mPa.s. The polymers were made into the following solutions (see Table 3) using the solution technique outlined by the manufacturer and diluted with lower alcohols including ethanol (IMS*), 2-propanol and 1-propanol.

Embodiment 2

[0088] Table 3 - Compositions of Examples 2A, 2B and 2C

[0089]

Example 2A

Example 2B

Example 2C

Mowiol 2-97 (20% solution)

50.0

50.0

50.0

IMS*

45.0

-

-

1-propanol

-

45.0

-

2-propanol

-

-

45.0

Deionized water

5.0

5.0

5.0

Total

100.0

100.0

100.0

[0090] As indicated in Table 4, the following results were obtained.

[0091] Table 4 - Properties of Examples 2A and 2C

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com