Power supply transformer

A technology for power transformers and casings, applied in transformers, fixed transformers, transformer/inductor casings, etc., can solve problems such as high prices and high manufacturing costs, and achieve the effects of preventing contact, easy assembly, and superior economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

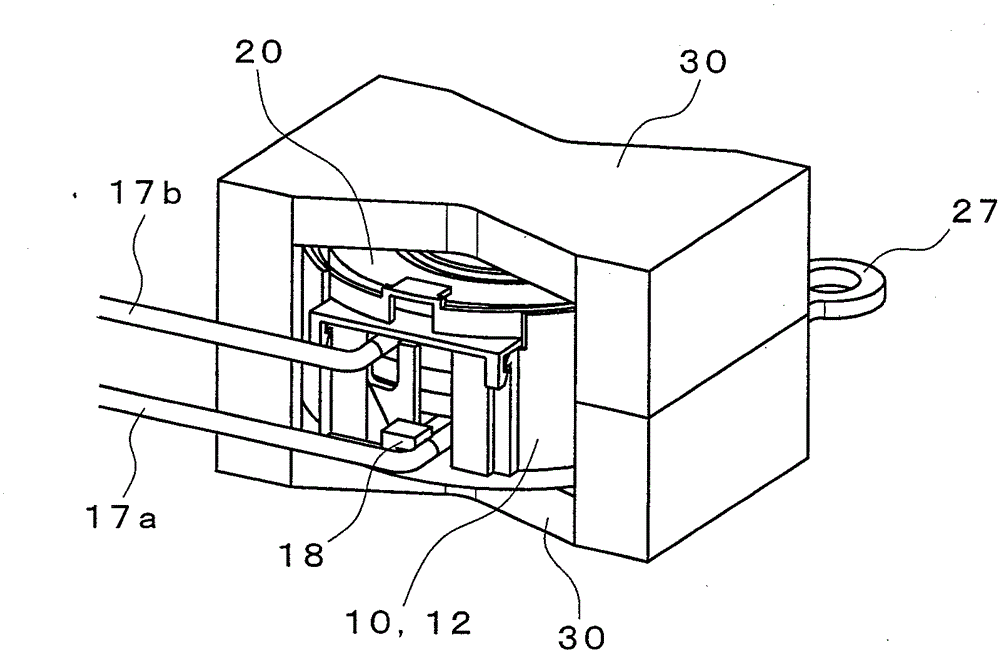

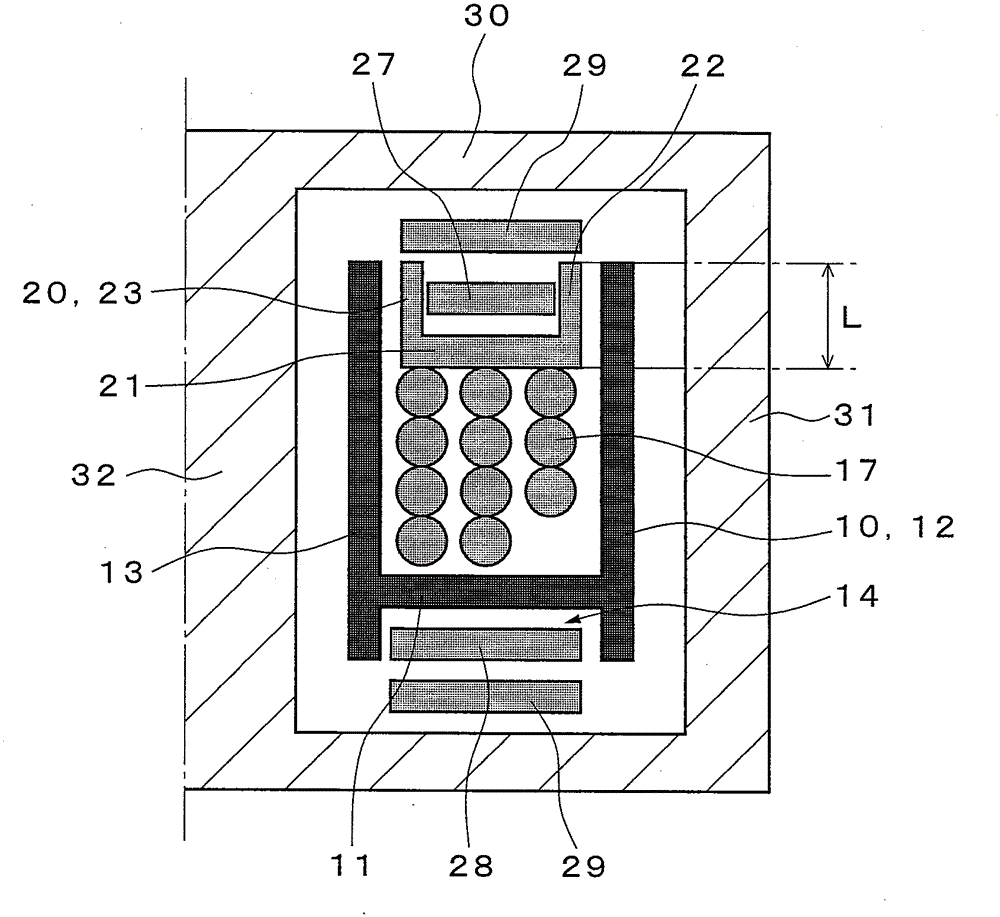

[0034] Figure 1~Figure 6 An embodiment of the power transformer of the present invention is shown, and the reference numeral 10 in the figure is a housing.

[0035] The casing 10 is made of a disc-shaped bottom plate 11, an outer cylinder 12 erected on the outer periphery of the bottom plate 11, and an inner cylinder 13 erected in a hole formed in the center of the bottom plate 11, and is made of insulating synthetic resin. An integrally formed double-layer cylindrical casing with a bottom.

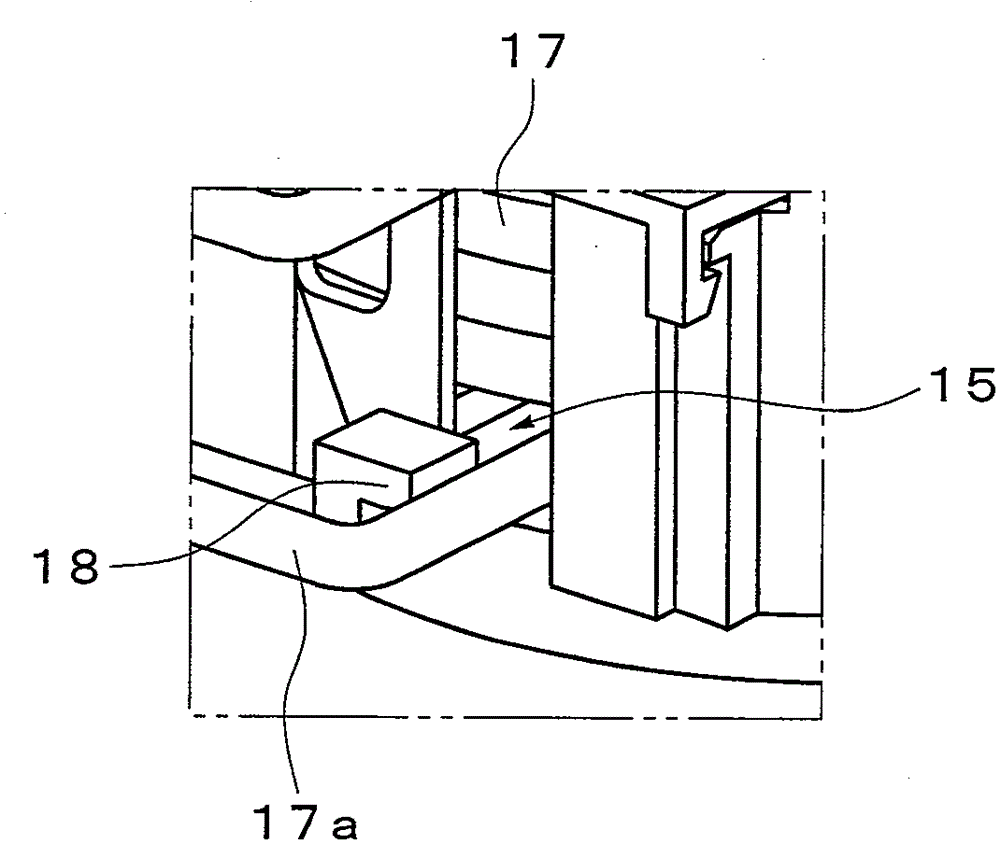

[0036] Here, the outer cylinder 12 and the inner cylinder 13 of the casing 10 are formed to protrude downward compared with the bottom plate 11, thereby forming a concave portion 14 on the back side of the bottom plate 11 (see Image 6 ). Further, a notch 15 extending from the upper opening to the bottom plate 11 is formed in the outer cylinder 11 , and a groove (guide portion) 16 opening at the notch 15 is formed in the bottom plate 11 . Then, the first coil 17 is accommodated betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com