Method for improving severe saline-alkali land

A technology for severe saline-alkali land and saline-alkali land, which is applied in the direction of soil preparation methods, applications, agricultural machinery and implements, etc. It can solve the problems of high cost of amendments and low soil pH adjustment ability, so as to improve soil, reduce salinity, and increase fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

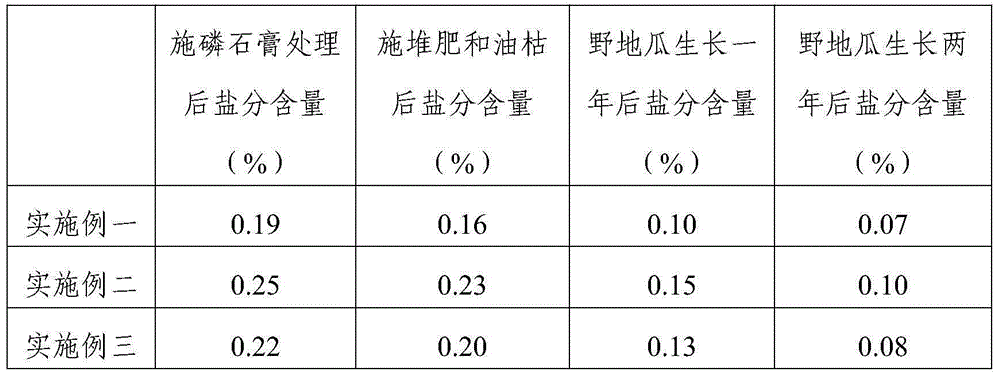

Embodiment 1

[0031] A method for improving severe saline-alkali land, comprising the following steps:

[0032] (1) Phosphogypsum pretreatment: dry the phosphogypsum until its moisture content is 3%, and then send it into a pulverizer for pulverization to obtain gypsum powder with a phosphorus fineness of 60 mesh;

[0033] (2) Pretreatment of saline-alkali land: the planting site is the saline-alkali land of Haixing Bingjie Farm, and the total salt content of the 0-20cm topsoil is 0.42%. In a ditch with a width of 20 cm and a ditch distance of 30 cm, phosphogypsum powder is evenly spread in the ditch and then filled with soil. The application rate of phosphogypsum powder is 1500 kg / mu, and then rotary tillage is carried out. After 14 days of filming, remove the film and carry out leaching treatment, then evenly apply compost and oily dryness in the saline-alkaline land, the application rates of compost and oily dryness are 1200kg / mu and 1000kg / mu respectively, and then carry out rotary till...

Embodiment 2

[0041] A method for improving severe saline-alkali land, comprising the following steps:

[0042] (1) Phosphogypsum pretreatment: dry the phosphogypsum until its moisture content is 7%, then send it into a pulverizer for pulverization, and obtain gypsum powder with a phosphorus fineness of 200 mesh;

[0043] (2) Pretreatment of saline-alkali land: the planting site is the saline-alkali land of Haixing Bingjie Farm, and the total salt content of the 0-20cm topsoil is 0.58%. For a ditch with a width of 30cm and a distance of 40cm, spread phosphogypsum powder evenly in the ditch and fill it with soil. The application rate of phosphogypsum powder is 2000kg / mu, and then perform rotary tillage treatment. The depth of the cultivated land is 12cm, and the film is covered. After 30 days, remove the film and carry out leaching treatment, and then evenly apply compost and oil dry in the saline-alkali land, the application rates of compost and oil dry are 1800kg / mu and 1500kg / mu respectiv...

Embodiment 3

[0051] A method for improving severe saline-alkali land, comprising the following steps:

[0052] (1) Phosphogypsum pretreatment: dry the phosphogypsum until its moisture content is 5%, then send it into a pulverizer for pulverization, and obtain gypsum powder with a phosphorus fineness of 80 mesh;

[0053] (2) Pretreatment of saline-alkali land: the planting site is the saline-alkali land of Haixing Bingjie Farm, and the total salt content of the 0-20cm topsoil is 0.52%. For a ditch with a width of 22cm and a distance of 35cm, spread phosphogypsum powder evenly in the ditch and fill it with soil. The application rate of phosphogypsum powder is 1800kg / mu, and then perform rotary tillage treatment. The depth of the cultivated land is 15cm, and the film is covered After 14 to 30 days, remove the film and perform leaching treatment, then evenly apply compost and oil dry in the saline-alkali land, the application rates of compost and oil dry are 1500kg / mu and 1200kg / mu respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com