Irrigation device for densely planted crops

An irrigator and irrigation technology, applied in the fields of botanical equipment and methods, watering devices, gardening, etc., can solve the problems of small flow, difficult to control operation, limited water infiltration range, etc., and achieve the effect of slowing down the water flow and preventing clogging. Good, the effect of shortening the irrigation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

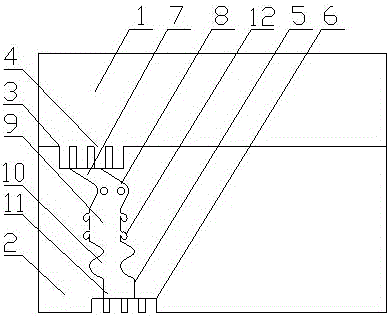

[0042] Such as figure 1 As shown, the emitter includes a water delivery chamber 1 and a water delivery chamber 2 sequentially extruded and vacuum formed along the inner surface of the water delivery chamber 1. The diameter of the water delivery chamber 1 is smaller than that of the irrigation chamber 2, and the water delivery chamber 2 is provided with an irrigation flow channel. 3. The water irrigation channel 3 is provided with four water inlets 4, energy dissipation and steady flow channels 5 and four water outlets 6. The water delivery chamber 1 communicates with the irrigation channel 3 through the water inlet 4, and the water outlet 6 communicates with the water irrigation channel 3. The energy-dissipating and steady-flow channel 5 is arranged radially along the irrigation chamber 2 and is composed of a water inlet section 7, a centrifugal section 8, a sedimentation section 9, an energy-dissipating section 10, and a water outlet section 11. The water inlet section 7. Cen...

Embodiment 2

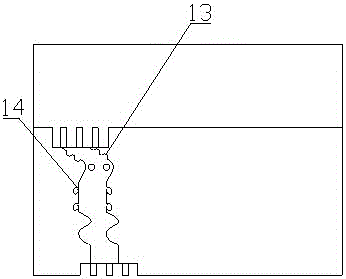

[0044] Such as figure 2 As shown, the difference from Embodiment 1 is that a sedimentation tank 13 is provided on the water inlet section 7, and the concave surface of the sedimentation tank 13 faces the inside of the energy dissipation and steady flow channel 5. When the water flow passes through the water inlet section 7, part of the mud The sand is deposited and deposited in the groove of the sedimentation tank 13, so that the cross-sectional area of the water inlet section 7 can not be reduced, so that the energy dissipation steady flow channel 5 can not be blocked; the opening 14 of the collection chamber 12 It is funnel-shaped, that is, the size of the side toward the flow path of the deposition section 9 is larger than the size of the side toward the inside of the collection chamber 12, which not only facilitates the entry of sediment into the collection chamber 12, but also The sediment is not easy to come out from the inside, and the anti-clogging effect is better....

Embodiment 3

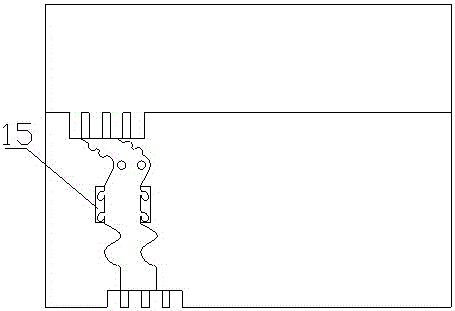

[0046] Such as image 3 As shown, the difference from Embodiment 1 is that a closed air pressure chamber 15 is provided at a position corresponding to the deposition section 9 in the irrigation chamber 2, and the air pressure chamber 15 is under negative pressure, and the air pressure chamber 15 connects the collection chamber 12 The outside is closed, and under the action of negative pressure, the collection chamber 12 is always kept open, which is more conducive to the deposition of sediment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com