A gas grid filter mixer and method

A filtering mixer, filtering method technology, applied in mixing methods, gas and gas/vapor mixing, chemical instruments and methods, etc., can solve the problems of low production efficiency, long time, can not well meet production requirements, etc. Easy to move, small footprint, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

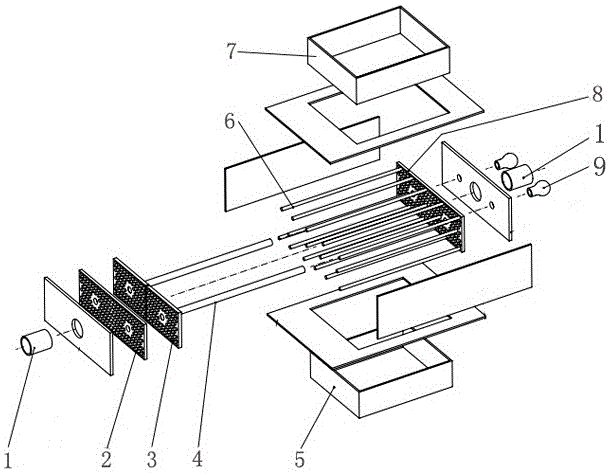

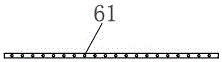

[0030] A gas grid filter mixer, comprising a housing, the interior of the housing is divided into a filter medium distribution chamber and a filter mixing chamber by a partition, a filter medium inlet 1 is arranged on the side wall of the filter medium distribution chamber, and the filter medium The top of the mixing chamber is provided with an inlet 7 for the gas to be filtered, and the outlet 5 for the filtered gas is provided at the bottom. A number of parallel porous nozzles 6 are arranged horizontally in the filter mixing chamber, and the ends of the porous nozzles 6 pass through the partition and enter the filter medium distribution chamber. , both sides of the porous nozzle 6 evenly offer a number of nozzle holes 61.

[0031] A scraper 3 parallel to the partition is also arranged vertically in the filter mixing chamber, and a number of holes for the porous nozzle 6 to traverse are provided on the scraper 3. One side of the scraper 3 is also fixedly connected to the pull ...

Embodiment 2

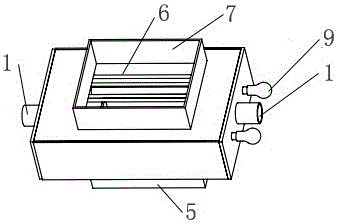

[0035] Such as figure 1 , 2 As shown, a gas grid filter mixer includes a housing, and inside the housing, there are two partitions, a partition 2 and a partition 2 8, which divide the inside of the casing into filter medium distributions from left to right. chamber, filter mixing chamber and filter medium distribution chamber, each filter medium distribution chamber has a filter medium inlet 1 on the side wall, the top of the filter mixing chamber is provided with a gas inlet 7 to be filtered, and the bottom is provided with a filtered gas outlet 5, A number of parallel porous nozzles 6 are arranged horizontally in the filter mixing chamber, and the two ends of the porous nozzles 6 respectively pass through the first partition 2 and the second partition 8 to enter a filter medium distribution chamber. Both sides of the porous nozzle 6 evenly offer some spray holes 61, such as image 3 shown.

[0036] A scraper 3 parallel to the partition is also arranged vertically in the f...

Embodiment 3

[0040] The first step is to set up a filter mixing chamber, in which a number of porous nozzles 6 with several nozzle holes 61 evenly opened on both sides are arranged in a layered and misplaced arrangement, and the ends of the porous nozzles 6 extend outwards out of the filter mixing chamber. room; a scraper 3 is also provided, and each porous nozzle 6 is vertically penetrated in it and can slide, and a pull rod 4 can be used to pull the scraper 3 to slide longitudinally along the porous nozzle 6 outside the filter mixing chamber;

[0041] In the second step, the filter medium is passed into each porous nozzle 6, and enters the filter mixing chamber through the nozzle hole 61 to form a multi-point sieve layout, and the gas to be filtered passes through the filter mixing chamber from the vertical direction, and the gas to be filtered Under the action of angle difference and speed difference, the two different substances with the filter medium move in the shape of "iron flower" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com