Efficient cooling and dust removal lifting tower

A lifting tower, high-efficiency technology, applied in casting molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc., can solve the problems of uneven air cooling, insufficient cooling, poor thermal conductivity, etc. To achieve the effect of avoiding equipment and reducing equipment power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

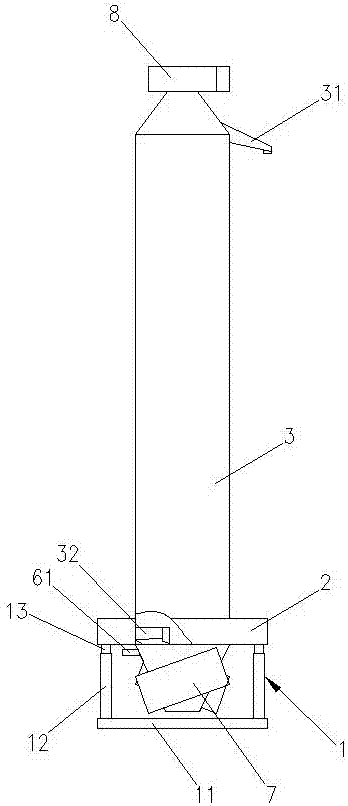

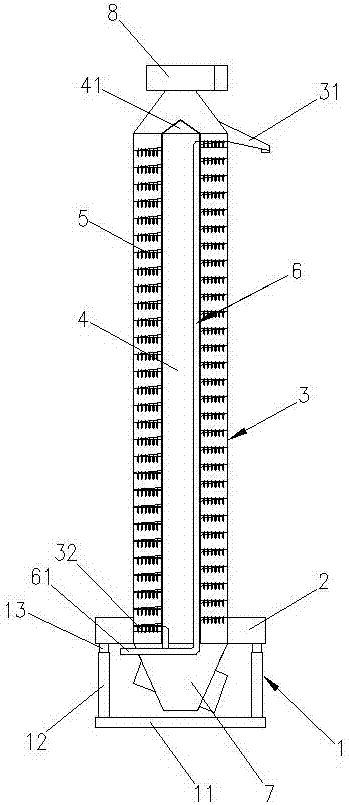

[0018] As shown in the figure, in order to achieve the above purpose, the technical solution adopted by the present invention is: efficient cooling and dedusting lifting tower, including:

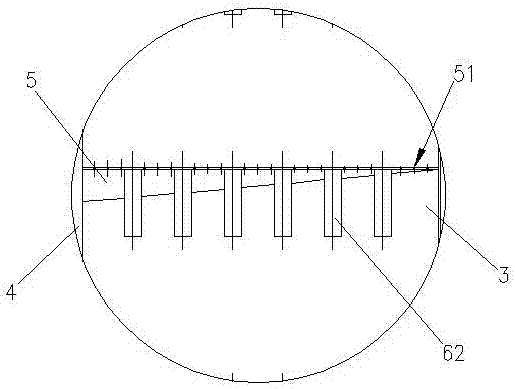

[0019] Machine base 1, material tray 2 and machine body 3, described material tray 2 is fixedly installed on the machine base 1, machine body 3 is fixedly installed in the material tray 2, is provided with discharge port 31 at the upper end of described machine body 3, and the lower end A feed port 32 is provided, which corresponds to the position of the feed tray 2; a central column 4 is provided in the middle of the inner cavity of the body 3, and a spiral trough 5 is provided between the central column 4 and the inner wall of the shell of the body 3 , the spiral trough 5 spirals up from bottom to top around the central column 4, and the head and tail are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com