Pouring type resin-based distributed optical fiber sensor packaging device

A distributed optical fiber and packaging device technology, applied in the field of distributed optical fiber sensors, can solve problems such as difficulty in realizing large-sized product preparation, and achieve the effects of good adhesion, good product flexibility, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

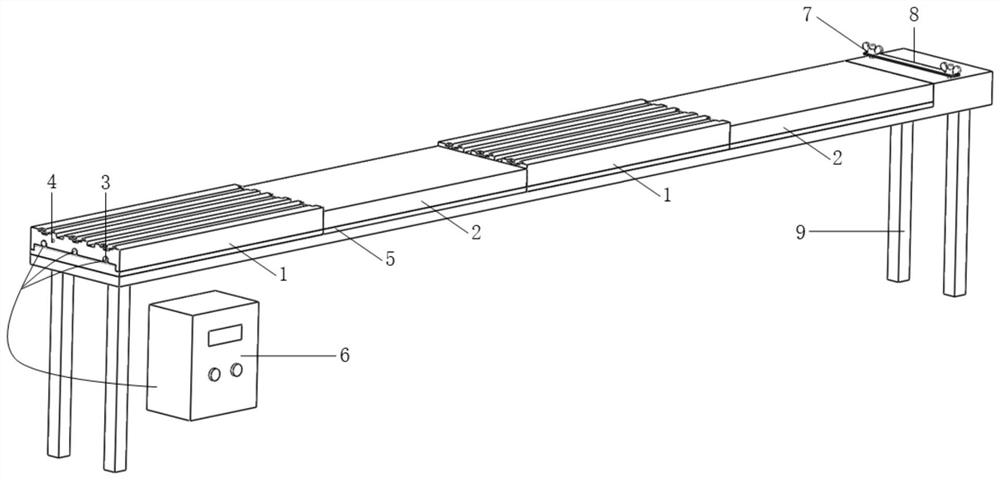

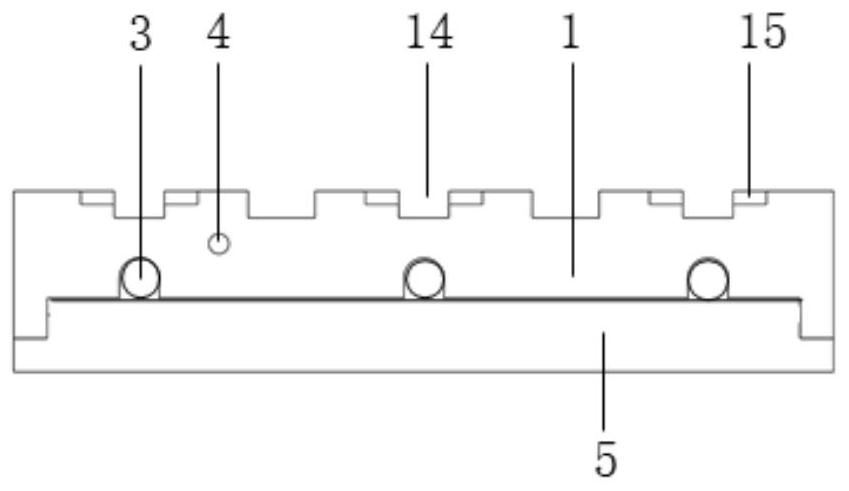

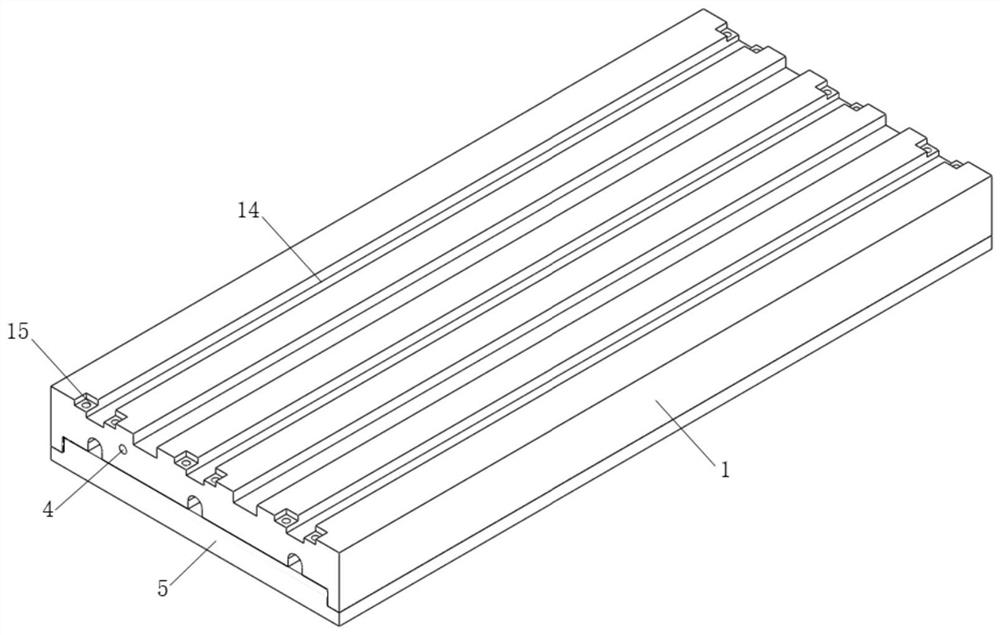

[0028] Specific implementation mode one: the following combination Figure 1-Figure 5 Describe this embodiment, a casting type resin-based distributed optical fiber sensor packaging device described in this embodiment, which includes: a casting mold 1, a vulcanization platform 2, an operating platform 9, a heat shield 5, a heating tube 3 and a temperature control box 6;

[0029] A heat insulation board 5 is laid on the top of the operating platform 9, and a pouring mold 1 and a vulcanization platform 2 are arranged at intervals on the heat insulation board 5. Grooves are arranged under the pouring mold 1 and the vulcanization platform 2, and heating pipes 3 are laid in the grooves. , the heating end of the heating pipe 3 is connected with the temperature control box 6 .

[0030] In this embodiment, the casting mold 1 and the vulcanization platform 2 are arranged at intervals, and the number of combinations is not limited. The segmented molding and vulcanization process is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com