Self-protected structure for rapidly fixing hydraulic tailstock and rejecting tip

A hydraulic tailstock and tip technology, which is applied in the direction of tailstock/top, tool holder accessories, turning equipment, etc., can solve the problems of tip surface damage, cumbersome operation, and affect production efficiency, so as to increase stability and improve accuracy , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

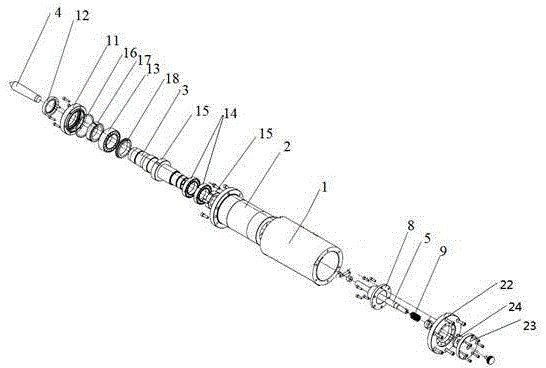

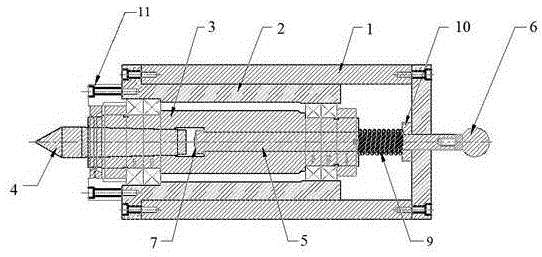

[0023] Such as figure 1 and figure 2 A self-protected quick-fixed hydraulic tailstock retracting top structure is shown, including: tailstock body 1, bushing 2, mandrel 3, top 4, push rod 5 and handle 6, the bushing 2 is composed of a shaft ring and a sleeve, the inner side of the sleeve is stepped, the bearing gland 11 is fixedly connected with the shaft ring through an inner hexagonal screw, and the mandrel 3 is respectively a front shaft and a rear shaft, so Both the front axle and the rear axle are stepped, the middle of the front axle and the rear axle is provided with a mounting groove, and the connecting part of the front axle and the rear axle is provided with a rectangular groove, and the tail of the top 4 and the ends of the push rod 5 are all arranged in the rectangular groove, the mounting groove inside the front axle is inclined from the rectangular groove to the front end, and the inclination of the mounting groove inside the front axle matches the top 4 .

[...

Embodiment 2

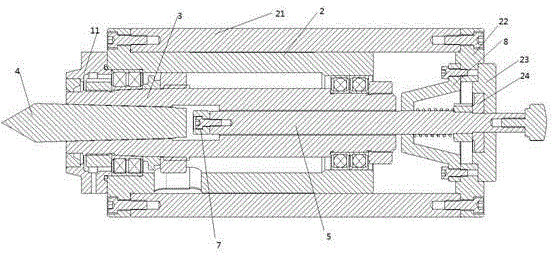

[0029] Such as figure 1 and image 3 A self-protected quick-fixed hydraulic tailstock retracting tip structure is shown, including: tailstock body 1, bushing 2, mandrel 3, tip 4, push rod 5 and handle 6, wherein the The tailstock body 1 is composed of a cylindrical body 21, a bearing sleeve end cover 22 and a tailstock push rod rear guide cover 23.

[0030] The relationship between the above components is as follows:

[0031] The shaft sleeve 2 is composed of a shaft ring and a sleeve, the inner side of the sleeve is stepped, the bearing gland 11 is fixedly connected with the shaft ring by a hexagon socket head screw, and the mandrels 3 are front shafts respectively. and the rear axle, the front axle and the rear axle are stepped, the middle of the front axle and the rear axle is provided with a mounting groove, and the connecting part of the front axle and the rear axle is provided with a rectangular groove, so The tail portion of the top 4 and the end of the push rod 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com