Washing device for engineering vehicle

A technology for cleaning devices and engineering vehicles, which is applied to vehicle exterior cleaning devices, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of unusable equipment, difficult maintenance and cleaning, long connection lines, etc., to increase service life. and efficiency, reduce the size of the control system, and increase the effect of power protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

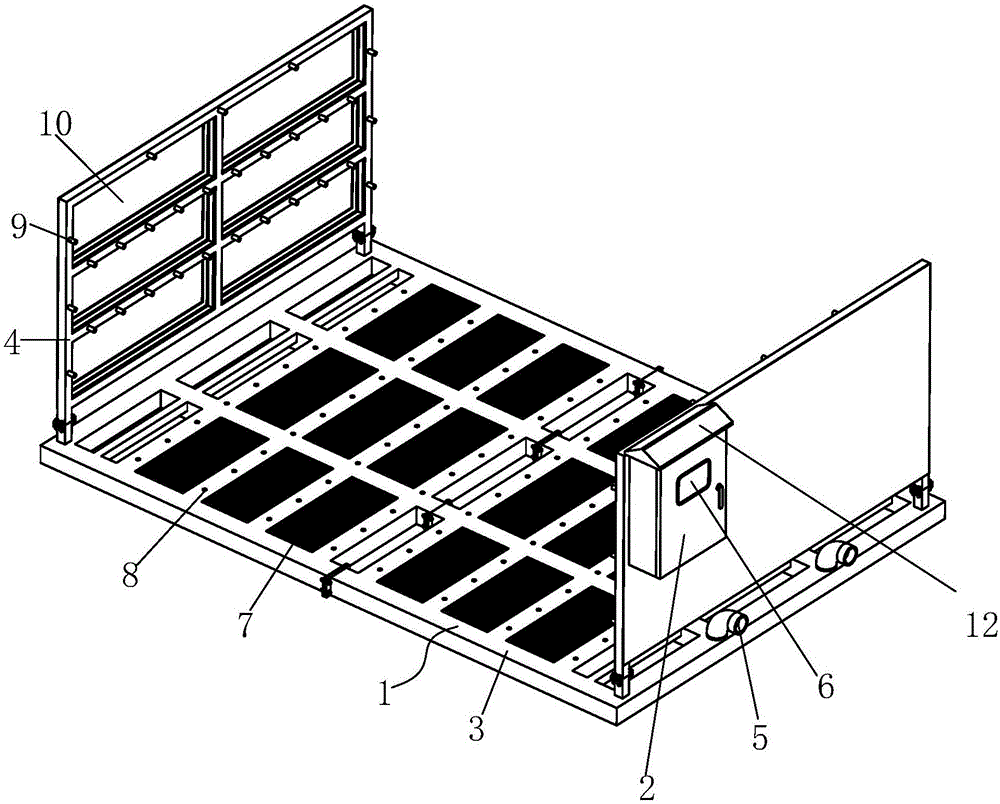

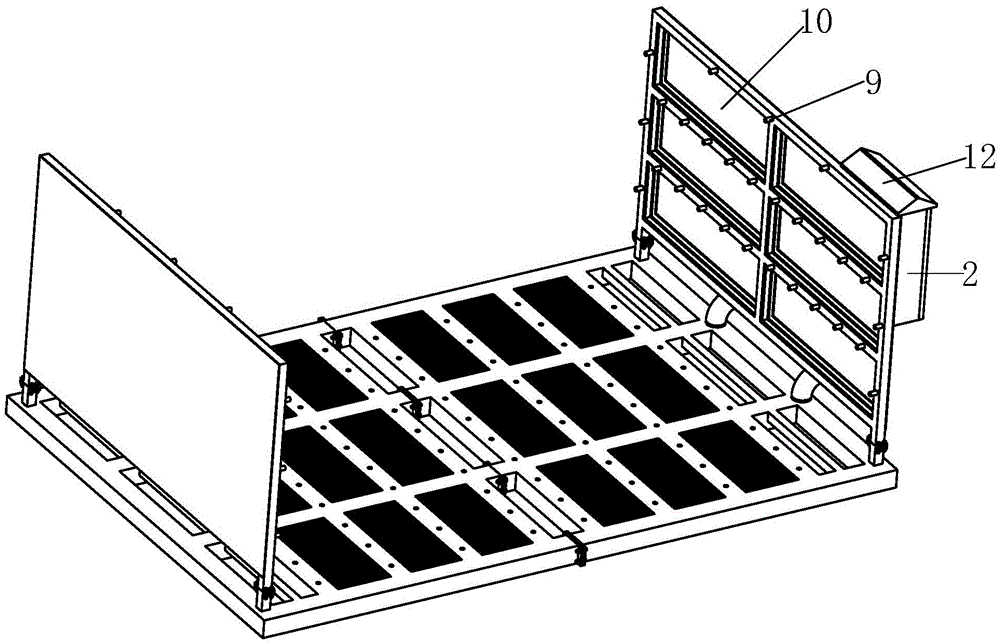

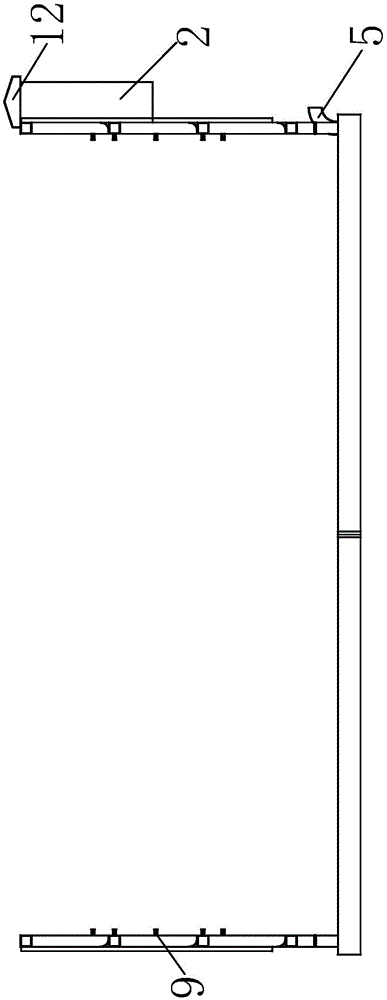

[0031] Such as Figure 1 to Figure 6 As shown, a cleaning device for engineering vehicles includes a frame 1 and a control box 2. The frame 1 includes a bottom plate 3 and side plates 4 fixedly installed on the left and right sides of the bottom plate 3 respectively. The inside of the bottom plate 3 is provided with a cavity structure, and the right side of the bottom plate 3 is installed with a water inlet 5 leading to the inner cavity of the bottom plate 3. The water inlet 5 is a hose interface, and the water inlet 5 is made of hard plastic reinforced pipe . Grid plates 7 are also laid on the base plate 3 , and a number of No. 1 nozzles 8 located between the grid plates 7 are evenly installed on the base plate 3 . The upper end surfaces of the No. 1 nozzles 8 are located below the upper end surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com