Automatic brick picking device

An automatic, brick-brick technology, applied in the field of automatic brick picking devices, can solve the problem of not being able to remove bricks automatically, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The substantive features and significant progress of the present invention will be described below in conjunction with specific implementation forms and accompanying drawings. It should be understood that these embodiments are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

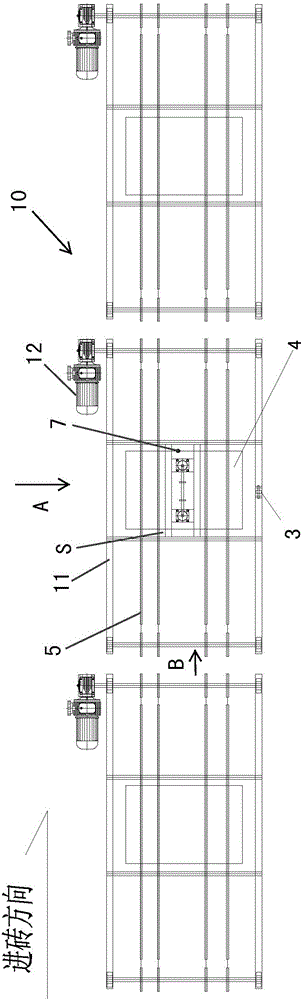

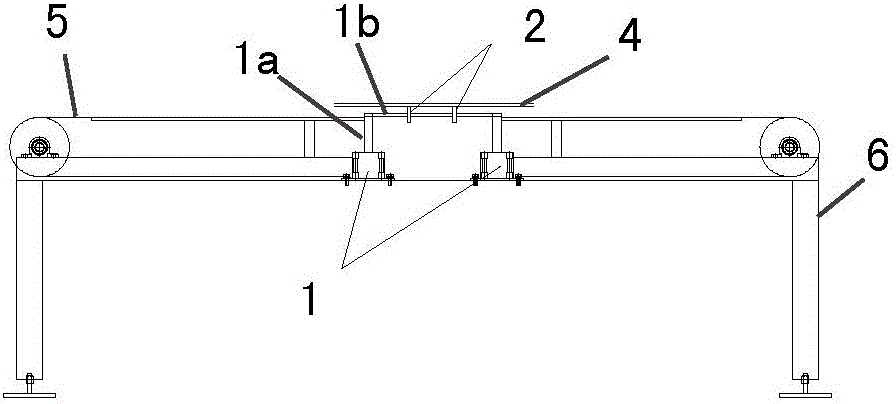

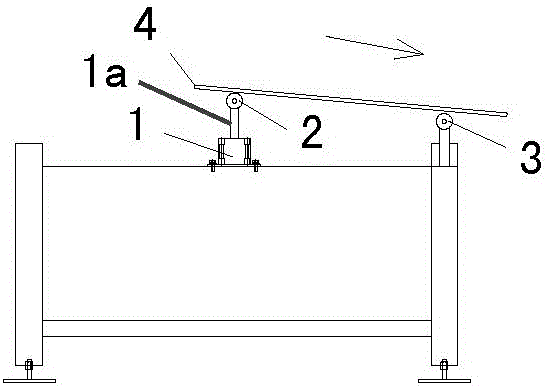

[0032] In order to solve the defects in the prior art that the labor intensity is high when picking bricks manually, and the belt of the conveying line is likely to fall off due to manual dragging of bricks, the present invention provides an automatic brick picking device, comprising: a bracket; and a conveying unit for conveying the adobe, the conveying unit includes at least one pair of conveying belts with intervals between each other; an ejection unit located in the interval and used for jacking up the adobe; a guiding unit for the adobe to slide down; and a control unit for controlling the ejecting un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com