Hydraulic winch with pneumatic clutch

A hydraulic winch and clutch technology, applied in the field of hydraulic winches, can solve the problems of complex clutch structure, insufficient compactness, unfavorable running stability, etc., and achieve the effects of good running stability, compact structure, and guaranteeing power transmission requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

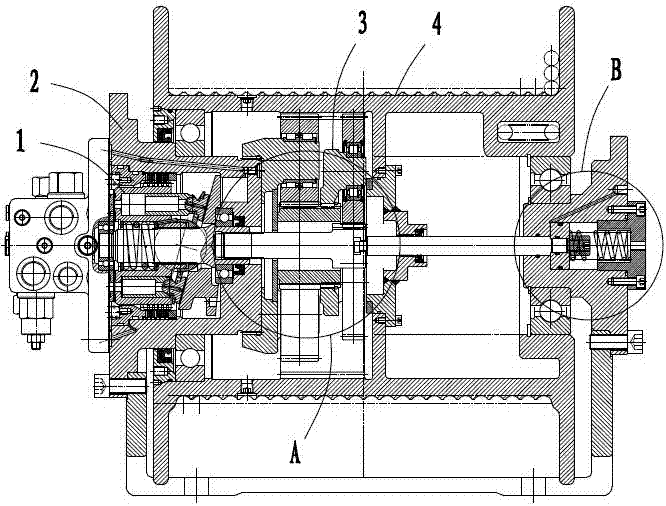

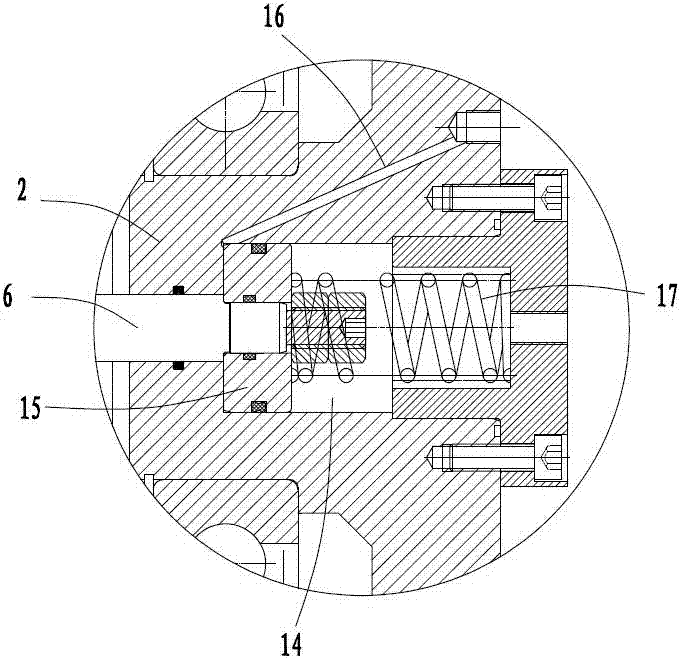

[0025] Embodiment: a kind of hydraulic winch with pneumatic clutch, from and off state respectively as follows Figure 5 , 1 shown. The device includes a frame 2, on which a hydraulic motor 1, a speed reduction device 3, and a reel 4 are sequentially arranged along the power transmission, and the frame is also provided with a cylinder 14 for driving the hydraulic motor and the speed reduction device clutch. Hydraulic motors and cylinders are respectively arranged at the left and right ends of the reel.

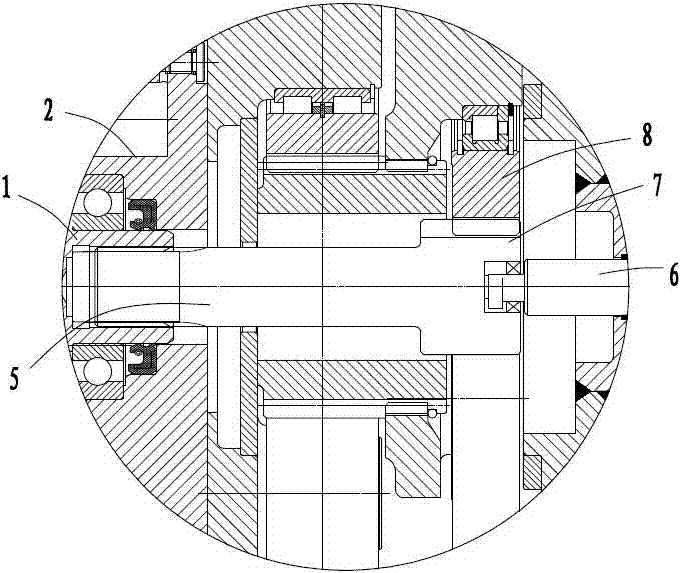

[0026] The hydraulic motor 1 is connected to the reduction device 3 through the telescopic sun gear shaft 5. The left end of the sun gear shaft is splined to the hydraulic motor. The right end of the sun gear shaft is provided with an end hole, and the left end of the tie rod 6 is plugged and fixed in the end hole. The right end of pull rod links to each other with cylinder 14. The sun gear shaft and the pull rod pass through the drum shaft along the axis.

[0027] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com