Negative thermal expansion modified asphalt caulking material

A technology of negative expansion material and modified asphalt, applied in the field of pavement material engineering, can solve the problems of mechanical damage, mutual separation, construction difficulties and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

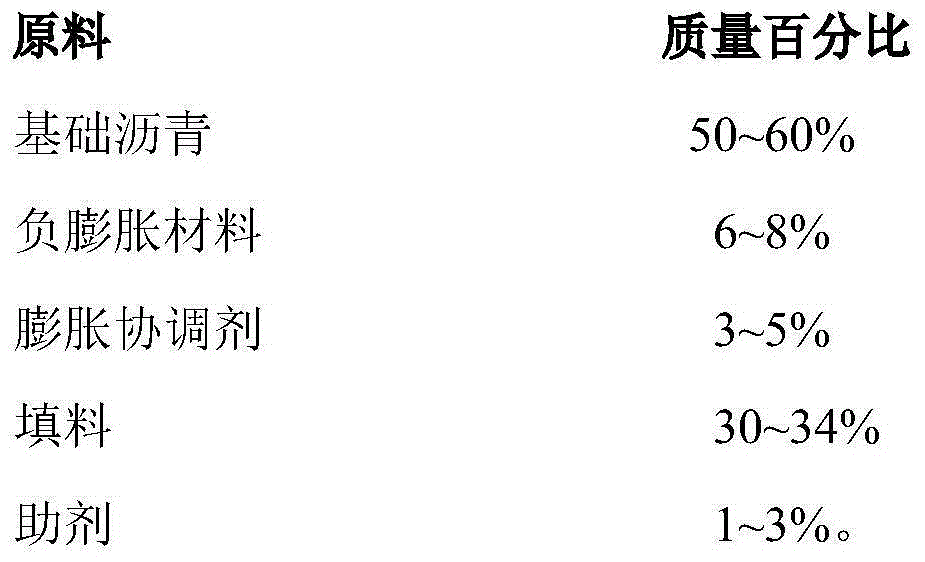

[0036] Taking the preparation of negative expansion modified asphalt joint filling material 100Kg as an example, the mass ratio of raw materials used is as follows:

[0037] SBS modified asphalt 55Kg

[0039] Sodium zirconium phosphate 4Kg

[0041] Polyoxypropylene polyoxyethylene copolymer 2Kg

[0042] The preparation method is as follows:

[0043] First, weigh 2Kg of polyoxypropylene-polyoxyethylene copolymer, 7Kg of zinc cyanide, and 4Kg of sodium zirconium phosphate, add 5Kg of alcohol to submerge the solids, heat the mixture and keep it at a temperature of 60°C, and stir for 15 minutes in a small cement mixing pot , after the alcohol is completely volatilized, grind it through a small cement mill for 10 minutes, and store the ground powder for later use;

[0044] Heat 55Kg of SBS modified asphalt to a molten state, then add the ground powder, and use a high-speed shearer to shear at a speed of 2000 rpm for 13 min...

Embodiment 2

[0047] Taking the preparation of negative expansion modified asphalt joint filling material 100Kg as an example, the mass ratio of raw materials used is as follows:

[0048] SBS modified asphalt 55Kg

[0049] Zinc cyanide 7Kg

[0050] Sodium zirconium phosphate 4Kg

[0051] Calcium powder 32Kg

[0052] Sodium polyacrylate 2Kg.

Embodiment 3

[0054] Taking the preparation of negative expansion modified asphalt joint filling material 100Kg as an example, the mass ratio of raw materials used is as follows:

[0055] SBS modified asphalt 45Kg

[0056] Zinc cyanide 10Kg

[0057] Sodium zirconium phosphate 4Kg

[0058] Calcium powder 38Kg

[0059] Polyoxypropylene polyoxyethylene copolymer 3Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com