A kind of eva adhesive film and preparation method thereof

An adhesive film and ethylene technology, applied in the field of EVA adhesive film and its preparation, can solve the problems of contamination of cells, welding strips or busbars, appearance folds of photovoltaic modules, etc., so as to solve production technical problems, reduce accumulation, and simple equipment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

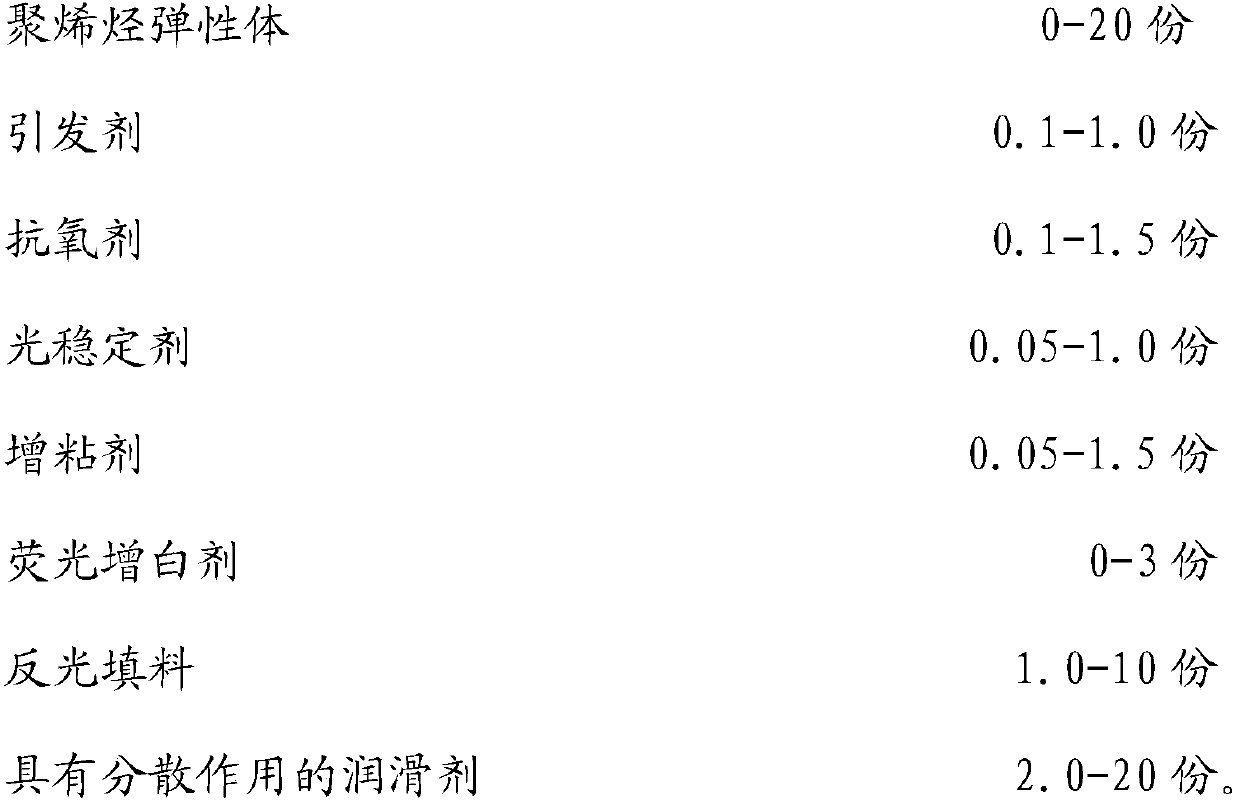

Method used

Image

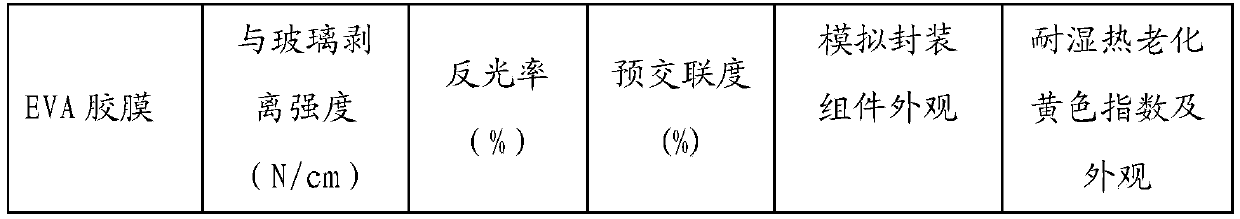

Examples

Embodiment 1

[0032] A kind of EVA adhesive film is prepared by the following method:

[0033] 1) Add 0.8 parts of tert-butyl peroxide-isopropyl carbonate, 0.8 parts of bis(3,5-tri Butyl-4-hydroxyphenyl) sulfide, 0.8 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.6 parts of vinyltriethoxysilane, 7 parts barium sulfate and 10 parts of zinc stearate, fully mixed, to obtain a mixture;

[0034] 2) Extrusion into film: put the mixture obtained in step 1) into the extruder, plasticize and extrude through the extruder, then pass through a mold to shape, and finally cool to form a film to obtain a semi-finished film; the extrusion of the extruder The temperature is 100°C, and the temperature of the mold is 120°C;

[0035] 3) Pre-crosslinking: pull out the semi-finished film obtained in step 2), pre-crosslink the semi-finished film by hot pressing, and finally cool and roll it to obtain a thickness of 0.7 mm and a surface roughness Ra of 0.5 μm EVA film.

[0036]The method of using hot ...

Embodiment 2

[0038] A kind of EVA adhesive film is prepared by the following method:

[0039] 1) Add 0.8 parts of tert-butyl peroxide-isopropyl carbonate, 0.8 parts of bis(3,5-tri Butyl-4-hydroxyphenyl) sulfide, 0.8 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.6 parts of vinyltriethoxysilane, 1.0 parts of 4, 4-bis(5-methyl-2-benzoxazolyl) stilbene, 7 parts of barium sulfate and 10 parts of zinc stearate were fully mixed to obtain a mixture;

[0040] 2) Extrusion into film: put the mixture obtained in step 1) into the extruder, plasticize and extrude through the extruder, then pass through a mold to shape, and finally cool to form a film to obtain a semi-finished film; the extrusion of the extruder The temperature is 110°C, and the temperature of the mold is 110°C;

[0041] 3) Pre-crosslinking: pull out the semi-finished film obtained in step 2), pre-crosslink the semi-finished film by hot pressing, and finally cool and roll it to obtain a thickness of 0.4mm and a surface rough...

Embodiment 3

[0044] A kind of EVA adhesive film is prepared by the following method:

[0045] 1) Add 0.8 parts of tert-butyl peroxy-isopropyl carbonate, 0.8 parts of bis(3,5-tri Butyl-4-hydroxyphenyl) sulfide, 0.8 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.6 parts of vinyltriethoxysilane, 7 parts of Titanium dioxide and 15 parts of butyl stearate are fully mixed to obtain a compound;

[0046] 2) Extrusion into film: put the mixture obtained in step 1) into the extruder, plasticize and extrude through the extruder, then pass through a mold to shape, and finally cool to form a film to obtain a semi-finished film; the extrusion of the extruder The temperature is 90°C, and the temperature of the mold is 110°C;

[0047] 3) Pre-crosslinking: pull out the semi-finished film obtained in step 2), pre-crosslink the semi-finished film by hot pressing, and finally cool and roll it to obtain a thickness of 0.4mm and a surface roughness Ra of 0.9 μm EVA film.

[0048] The method of usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com