Weather-proof steel support for bridge

A weather-resistant steel and bridge technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting the service life of bearings, bearing corrosion, etc., and achieve the effects of simple structure, excellent wear resistance, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

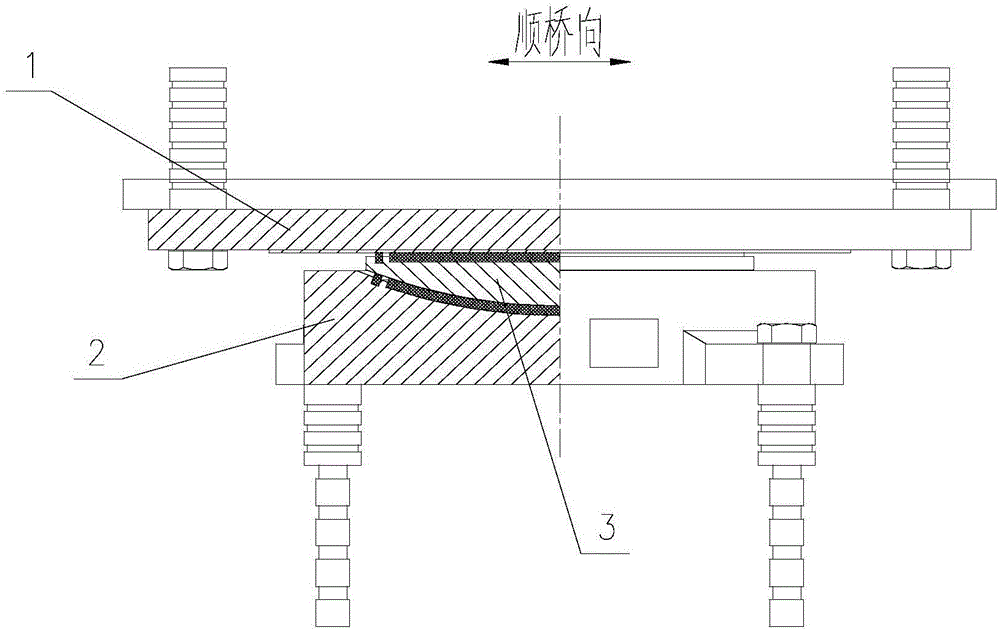

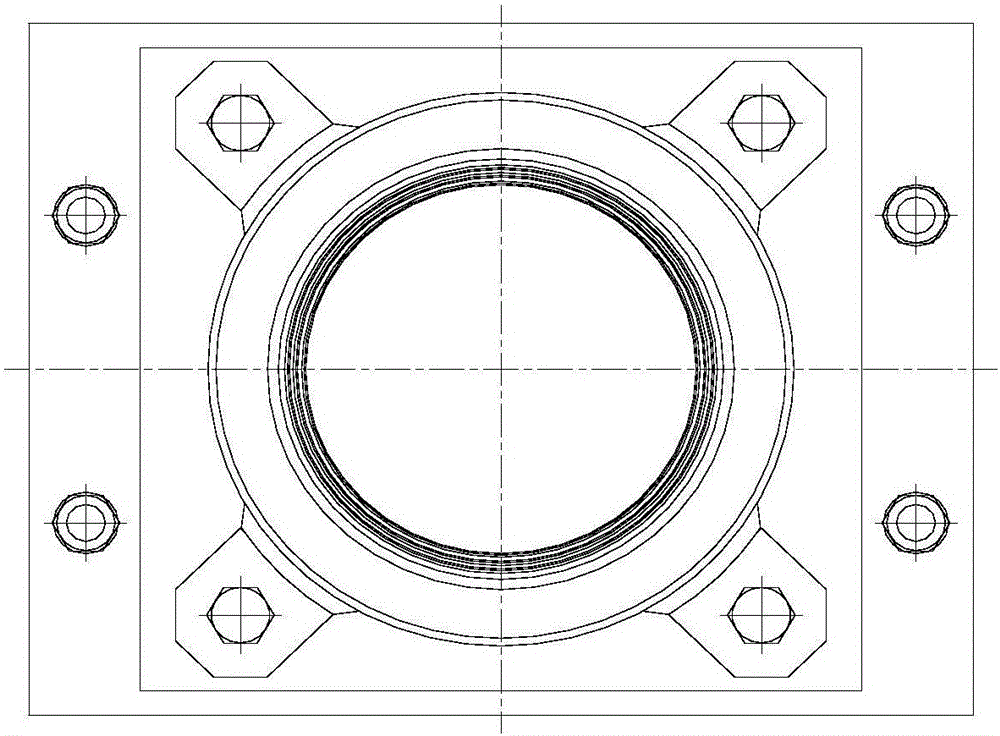

[0027] see figure 1 and figure 2 , a weather-resistant steel bearing for a bridge, including an upper bearing plate 1 and a lower bearing plate 2, and a spherical crown lining plate 3 is installed between the upper and lower bearing plates 1 and 2 to form a multi-directional movable spherical bearing. The upper bearing plate 1, the lower bearing plate 2 and the spherical crown lining plate 3 are all made of weathering steel, and a protective rust layer is set on the surface of the upper and lower bearing plates 1 and 2, and the spherical crown lining plate 3 has The surface of Hawker metal surface is processed by mirror surface processing method, and nickel-phosphorus alloy coating is provided on the surface of the spherical crown liner 3 .

Embodiment 2

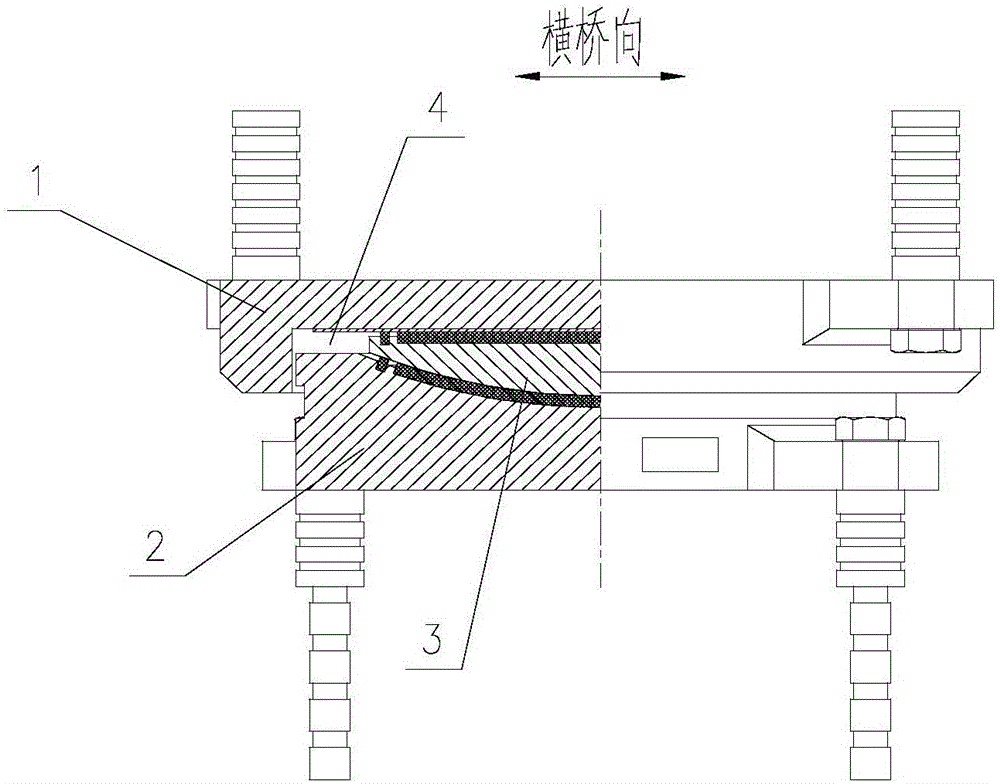

[0029] see image 3 and Figure 4 , a bridge weather-resistant steel bearing, comprising an upper bearing plate 1 and a lower bearing plate 2, the bottom surface of the upper bearing plate 1 is provided with a groove 4 matching the lower bearing plate 2, and the top of the lower bearing plate 2 is Cooperate installed in the groove 4, and install the spherical crown liner 3 between the upper and lower bearing plates 1, 2 to form a fixed spherical bearing. The upper bearing plate 1, the lower bearing plate 2 and the spherical crown lining plate 3 are all made of weathering steel, and a protective rust layer is set on the surface of the upper and lower bearing plates 1 and 2, and the spherical crown lining plate 3 has The surface of Hawker metal surface is processed by mirror surface processing method, and nickel-phosphorus alloy coating is provided on the surface of the spherical crown liner 3 .

Embodiment 3

[0031] see Figure 5 and Image 6 , the difference between this embodiment and Embodiment 1 is that the bottom surface of the upper support plate 1 is provided with lateral stoppers 5 on both sides of the top of the lower support plate 2 along the bridge direction, and the lateral stoppers 5 are connected by bolts. 6 is fixed on the bottom of the upper support plate 1, and a shear pin 7 is fitted between the upper support plate 1 and the lateral stopper 5, thereby forming a longitudinal movable spherical support. The stopper 5 is a stopper made of weathering steel, and a protective rust layer is provided on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com