Cantilever frame beam side all-embedded mounting and erecting device

A technology of pre-embedded devices and cantilever frames, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve problems such as discounting construction quality, discounting design strength, and delaying construction progress, so as to provide project progress and follow-up Smooth construction and improved construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

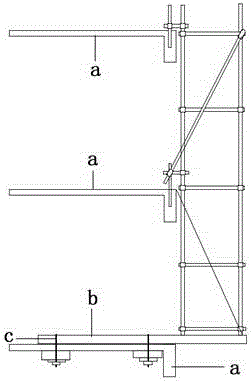

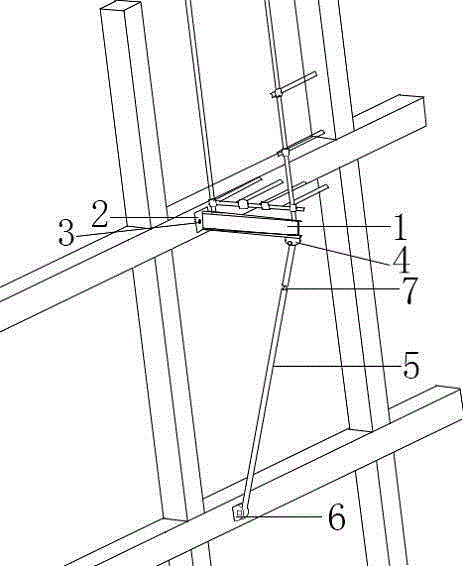

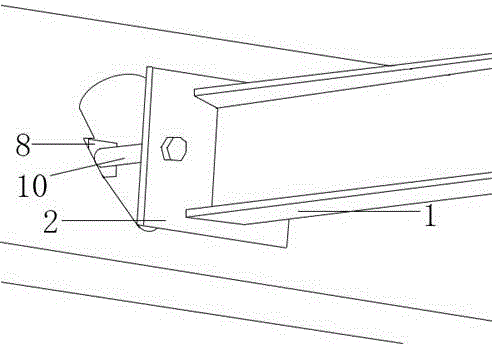

[0029] In the prior art, such as Figure 10 , 11 As shown, according to the "Steel Steel Scaffolding Specification", the maximum scaffolding height is 18m plus 1.5m railing, a total of 19.5m; the inner pole 17 is 0.3m away from the outer wall of the building structure 15, and the horizontal distance between the inner pole 17 and the outer pole 16 is 0.9m, the longitudinal distance is 1.5m, and the step distance is 1.8m. A horizontal sweeping rod 24 and a vertical sweeping rod 25 are arranged at a height of 200 mm on the top surface of the I-beam 1 . The horizontal sweeping bar 24 is fixed on the bottom of the vertical bar with a fastener, and then on the horizontal sweeping bar 24, the longitudinal sweeping bar 25 is fixed on the bottom of the vertical bar with a fastener to ensure the overall stability of the fastener steel pipe scaffold. The outer facade of the fastener steel pipe scaffold is covered with scissor braces 23 with a span of 4 and 6m, and between the outer pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com