Spring supporting and hanging bracket for gas compression pipeline and installation technology of spring supporting and hanging bracket

A gas compression and installation process technology, applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of combustible gas leakage, fire or explosion, gas pipeline vibration, etc., to achieve low natural vibration frequency, Simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with embodiments.

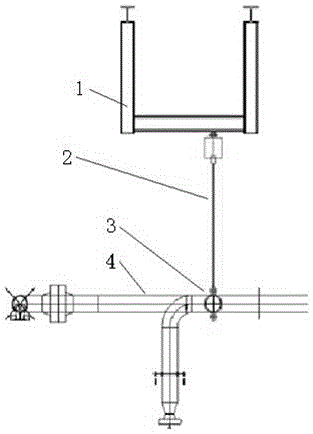

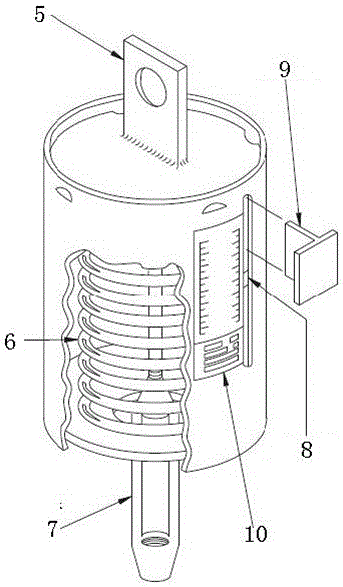

[0040] refer to figure 1 , figure 2 As shown, a spring support hanger for a gas compression pipeline, the spring support hanger 2 is connected to the structural frame 1 and the pipeline 4, and the spring support hanger 2 is connected to the structural frame 1 through the suspension connecting piece 5, so The spring support hanger 2 is connected to the pipeline 4 below through the hanger connecting rod 7, and is limited by the pipe clip 3. The spring support hanger 2 includes a spring coil 6, and the spring support hanger 2 is provided with an indicator Device 8, preload pin 9 and stroke proportional device 10.

[0041] An installation process of the spring support and hanger of the gas compression pipeline according to claim 1, comprising the following steps:

[0042] Step 1) According to the drawings and stress calculations, build a model of the high-pressure gas pipeline at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com