Gas-liquid separator capable of controlling lubricating oil circulation volume and control method thereof

A gas-liquid separator and lubricating oil technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of heat exchange efficiency decline of heat exchangers, compressor efficiency decline, and evaporator heat exchange efficiency reduction, etc. Achieve effective control, simple structure, improve stability and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

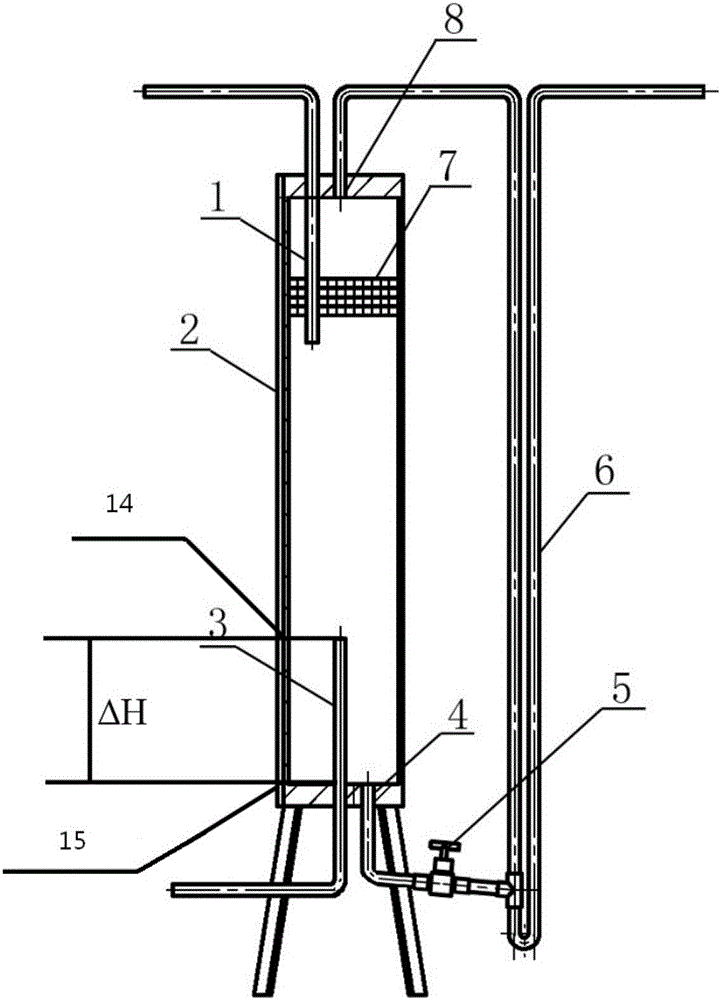

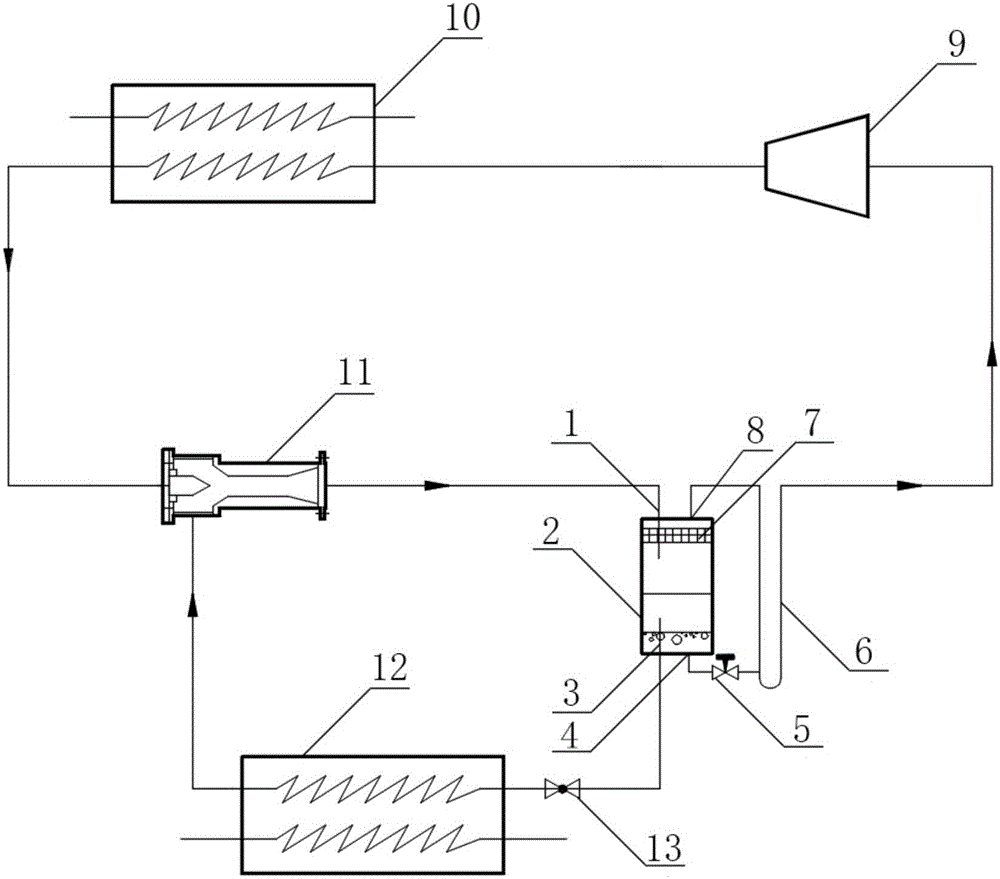

[0041] Such as figure 1As shown, the gas-liquid separator of the present embodiment includes: a tank body 2, a three-phase fluid pipe 1 entering from the top of the tank body 2, a liquid outlet pipe 3 entering from the bottom of the tank body 2, and a gas outlet pipe located at the top of the tank body 2. Outlet 8, the U-shaped pipe 6 connected to the gas outlet 8 at the upper port, the oil outlet 4 located at the bottom of the tank body 2 and connected to the U-shaped bend of the U-shaped pipe 6, and the regulating valve 5 for controlling the flow of the oil outlet 4 , and the liquid filter layer 7 located below the gas outlet 8; the U-shaped bend is the oil return section, and the oil delivery pipe where the regulating valve 5 is located is at an inclination angle of 5° from the horizontal plane. The function of the liquid filter layer 7 is to remove The small liquid droplets strengthen the gas-liquid separation effect; the liquid outlet of the liquid outlet pipe 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com