Environmental protection dust collection room for grain dryer

A grain dryer and dust collection room technology, applied in the direction of drying solid materials, drying, separation methods, etc., can solve problems such as failure to meet production environmental protection requirements, affect the health of operators, and air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and specific embodiments.

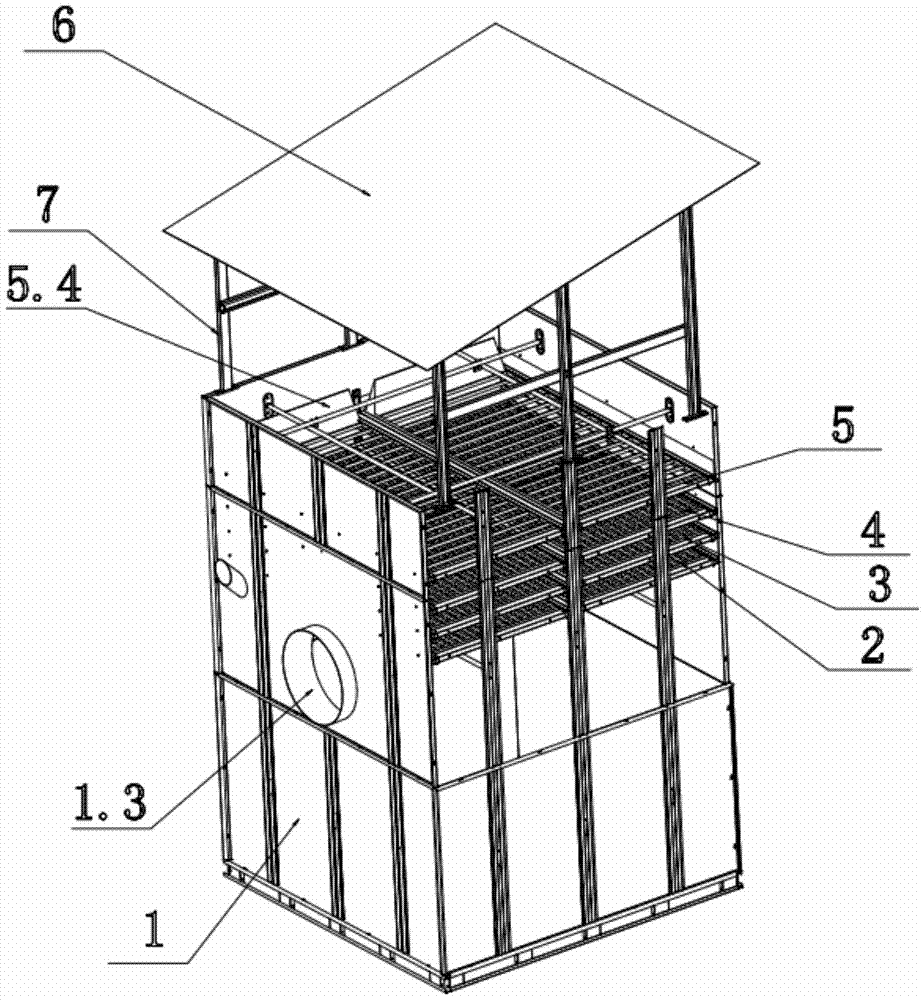

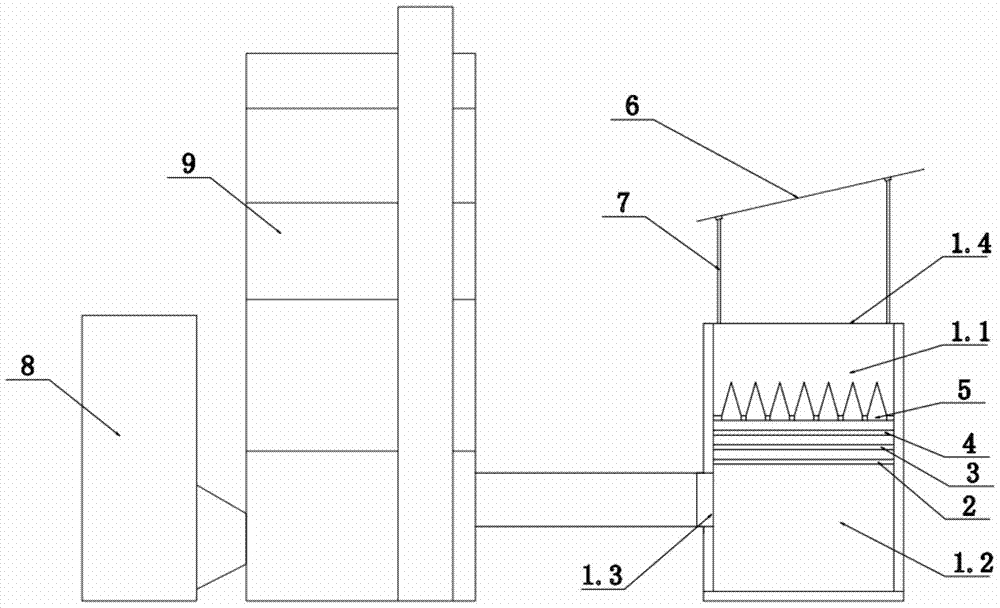

[0025] As shown in the figure, the present invention provides an environmentally friendly dust collection room for grain dryers, which includes a box body 1 inside which is provided with a chamber that divides the inner cavity of the box body 1 into an upper chamber 1.1 and a lower chamber 1.2 The filter screen group, the lower chamber 1.2 is provided with an inlet 1.3, and the upper chamber 1.1 is provided with an outlet 1.4 for exhaust gas in the lower chamber 1.2 to be discharged after passing through the filter screen group. The filter screen group includes a preliminary filter screen And the top filter mechanism 5 located above the primary filter screen.

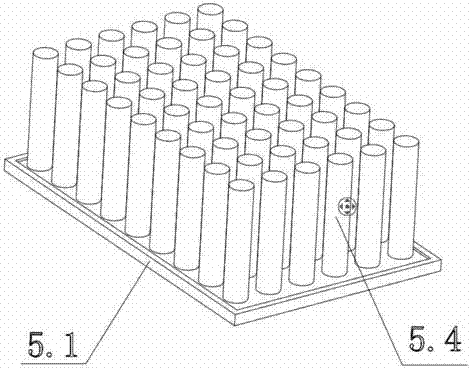

[0026] The top filter mechanism 5 includes a frame 5.1 whose outer surface is fixed and sealed to the inner wall of the box 1, and is arranged in the frame 5.1 and divides the plane enclosed by the inner su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com