Guide system applied to double-shield tunneling machine and positioning method

A technology of a tunnel boring machine and a guiding system, which is applied to the field of guidance during the construction of a tunnel boring machine, can solve the problems of increasing data errors, increasing time costs, time-consuming and the like, so as to increase the measurement distance, improve the construction efficiency, and reduce the frequency of station changing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

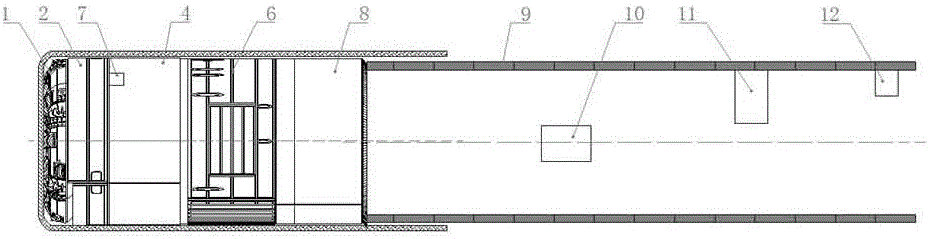

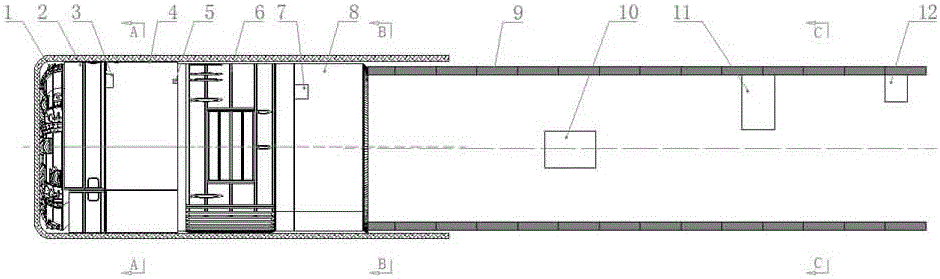

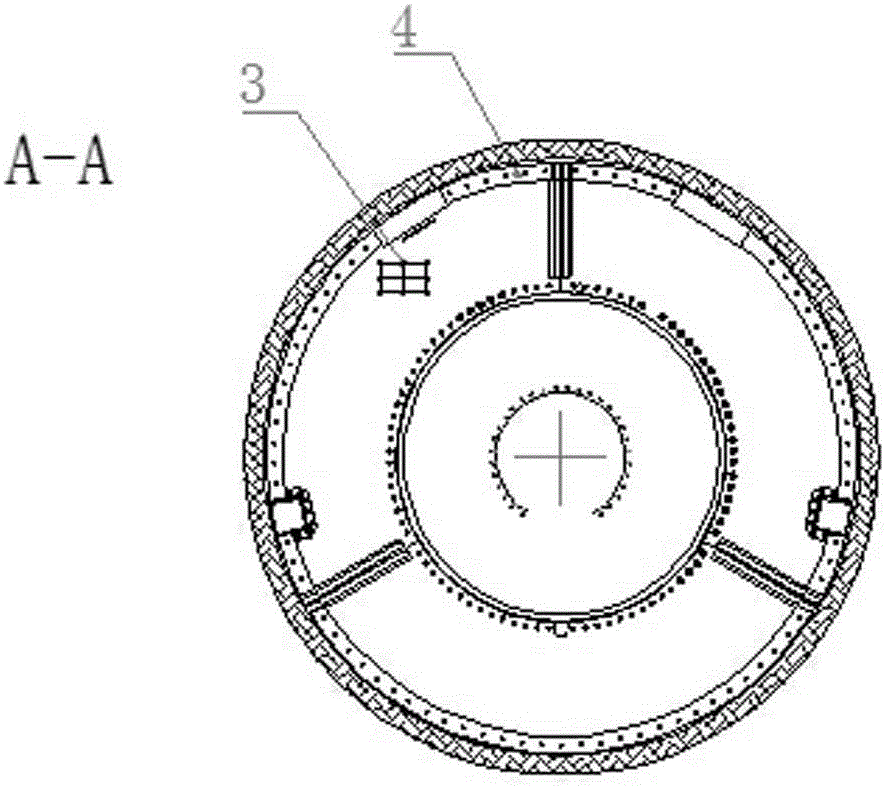

[0023] see Figure 2 to Figure 5 , the guide system of the present invention includes the rearview prism 12 installed on the segment wall 9, the total station 11 installed on the segment wall 9, the industrial computer 10 installed with the guide system installed in the driver's cab, installed on the The CCD measurement camera 5 on the support shield 6, the LED standard feature point 3 installed on the front shield 2, and the laser target 7 installed on the tail shield 8, the CCD measurement camera 5 and the total station 11 communicate with the industry through data lines The computer 10 is connected.

[0024] The present invention utilizes the CCD measuring camera 5 to realize real-time high-precision positioning measurement at a short distance. The principle is to obtain images of the surrounding scenery through the camera, use some natural or artificial features in the scenery, and obtain the surrounding environment model through image processing methods to achieve precis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com