Manufacture method of touch screen and touch screen

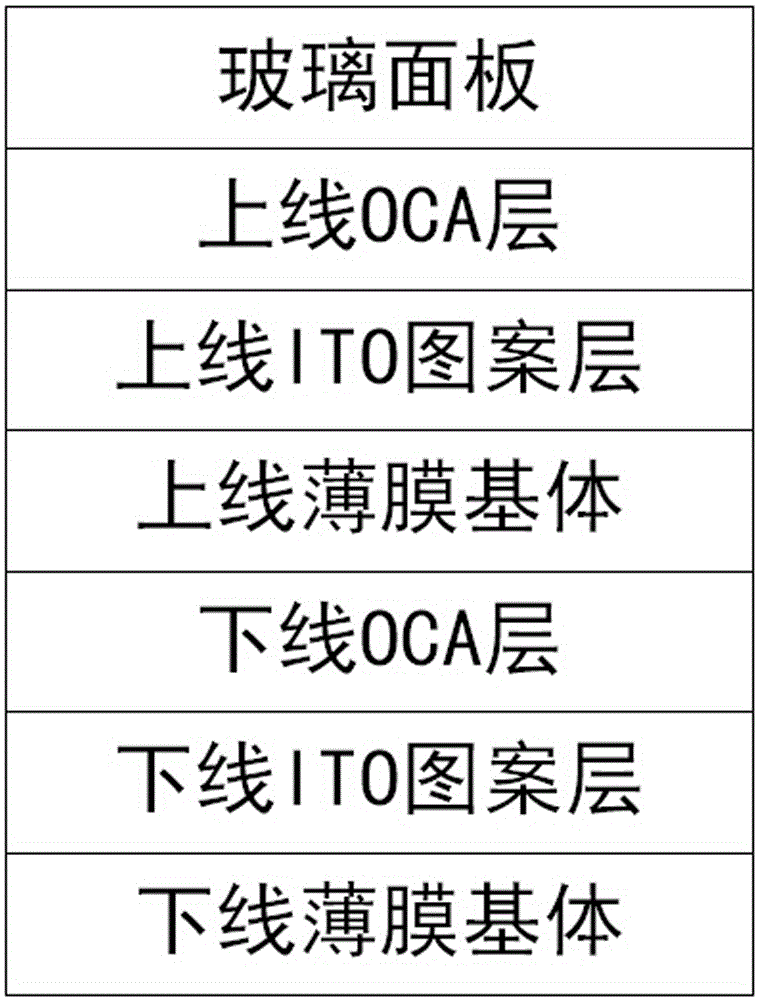

A production method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of poor yield rate of GFF architecture, poor price controllability, broken ITO lines, etc. Achieve the effect of reducing the thickness of the whole machine, lowering the cost and increasing the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

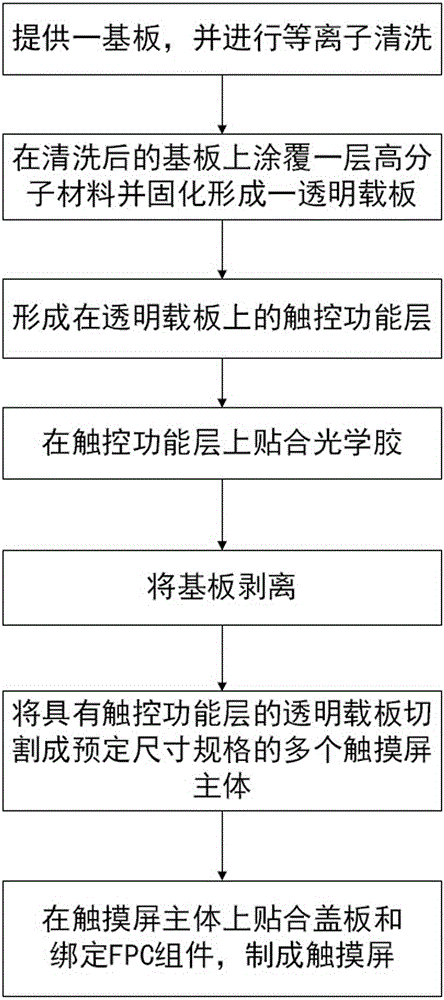

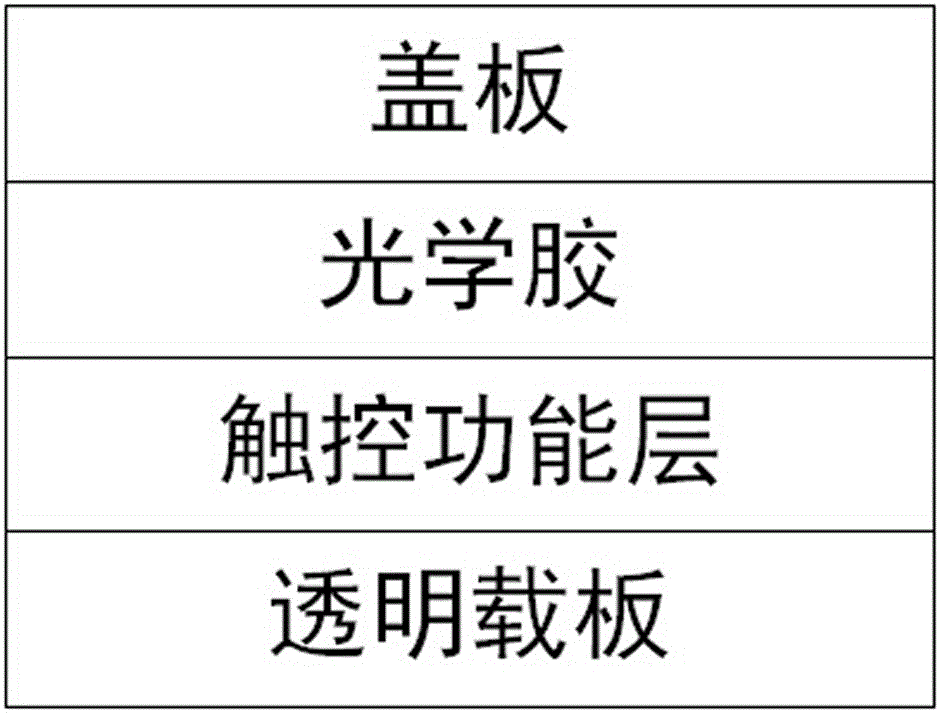

[0062] Such as Figure 4 Shown, a kind of manufacturing method of touch screen specifically comprises the following steps:

[0063] (1) Provide a substrate and perform plasma cleaning;

[0064] (2) Coat a layer of polyimide on the cleaned substrate and cure to form a transparent carrier with a thickness of about 1 μm;

[0065] (3) A layer of ITO film is sputtered on the transparent carrier; the required ITO functional pattern is etched on the ITO film according to the preset functional pattern, and a thickness of about 0.01 μm is directly formed on the transparent carrier. ITO functional pattern layer; during specific implementation, a layer of insulating layer can also be coated on the ITO functional pattern layer;

[0066] (4) Paste an OCA optical adhesive with a thickness of about 10 μm on the ITO functional pattern layer prepared in step (3); the optical adhesive has been hollowed out in advance for binding positions;

[0067] (5) Peel off the substrate, and coat a PE p...

Embodiment 2

[0077] Such as Figure 6 Shown, a kind of manufacturing method of above-mentioned touch screen specifically comprises the following steps:

[0078] (1) Provide a substrate and perform plasma cleaning;

[0079] (2) Coat a layer of polyimide on the cleaned substrate and cure to form a transparent carrier with a thickness of about 25 μm;

[0080] (3) A touch function layer with a thickness of about 20 μm formed above the transparent carrier; it specifically includes the following steps:

[0081] A layer of ITO film is sputtered on the transparent carrier, and etched into an ITO bridge;

[0082] Silk-screen insulating oil on the ITO bridge and solidify to form an insulating layer;

[0083] A layer of ITO film is sputtered on the insulating layer, and the required ITO functional pattern is etched on the ITO film according to the preset functional pattern to obtain the ITO functional pattern layer;

[0084] Silk-screen photosensitive silver paste on the ITO functional pattern la...

Embodiment 3

[0097] Such as Figure 8 Shown, a kind of manufacturing method of touch screen specifically comprises the following steps:

[0098] (1) Provide a substrate and perform plasma cleaning;

[0099] (2) Coat a layer of polyimide on the cleaned substrate and cure to form a transparent carrier with a thickness of about 100 μm;

[0100] (3) A touch function layer with a thickness of about 5 μm formed above the transparent carrier; it specifically includes the following steps:

[0101] A layer of ITO film is sputtered on the transparent carrier; the required ITO functional pattern is etched on the ITO film according to the preset functional pattern, and an ITO functional pattern layer directly formed on the transparent carrier is obtained;

[0102] Apply OC insulating glue on the ITO functional pattern layer and cure to form an insulating layer;

[0103] Silver paste is screen-printed on the insulating layer and solidified to obtain a conductive pattern layer;

[0104] (4) Lay an O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com