Pumpjetpropulsor hydraulic model with front stators circumferentially and asymmetrically arranged and design method thereof

A technology of symmetrical arrangement and hydraulic model, which is applied in instrumentation, calculation, special data processing applications, etc., to achieve the effect of easy expansion and promotion of popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

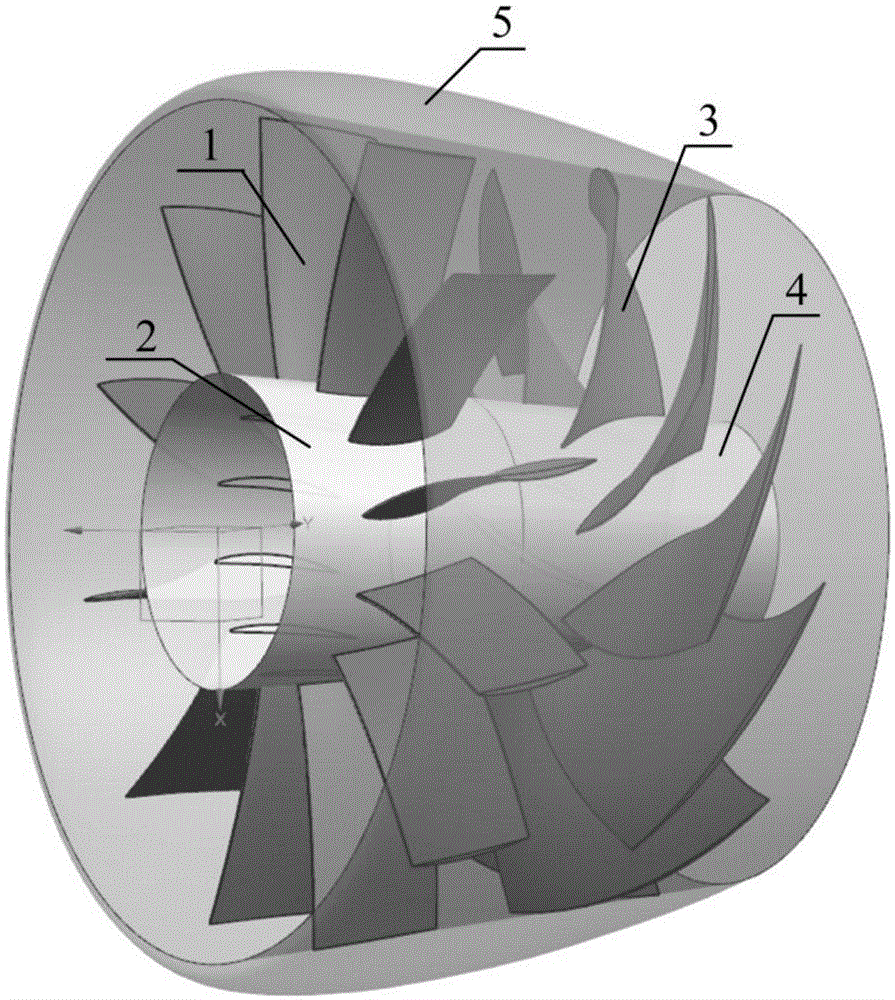

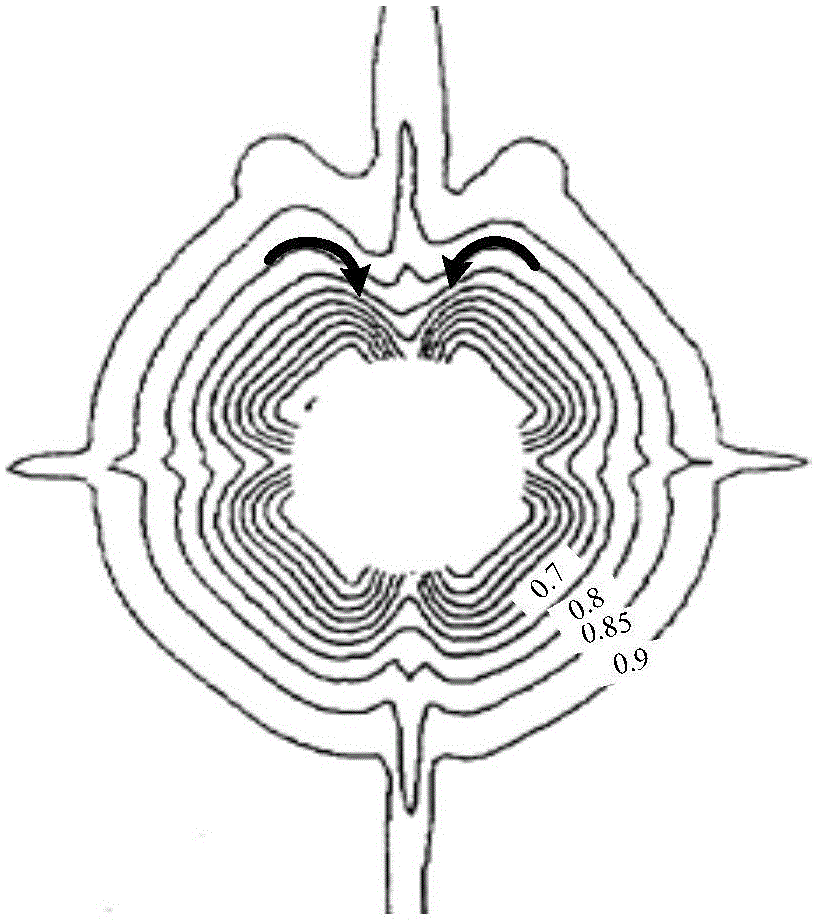

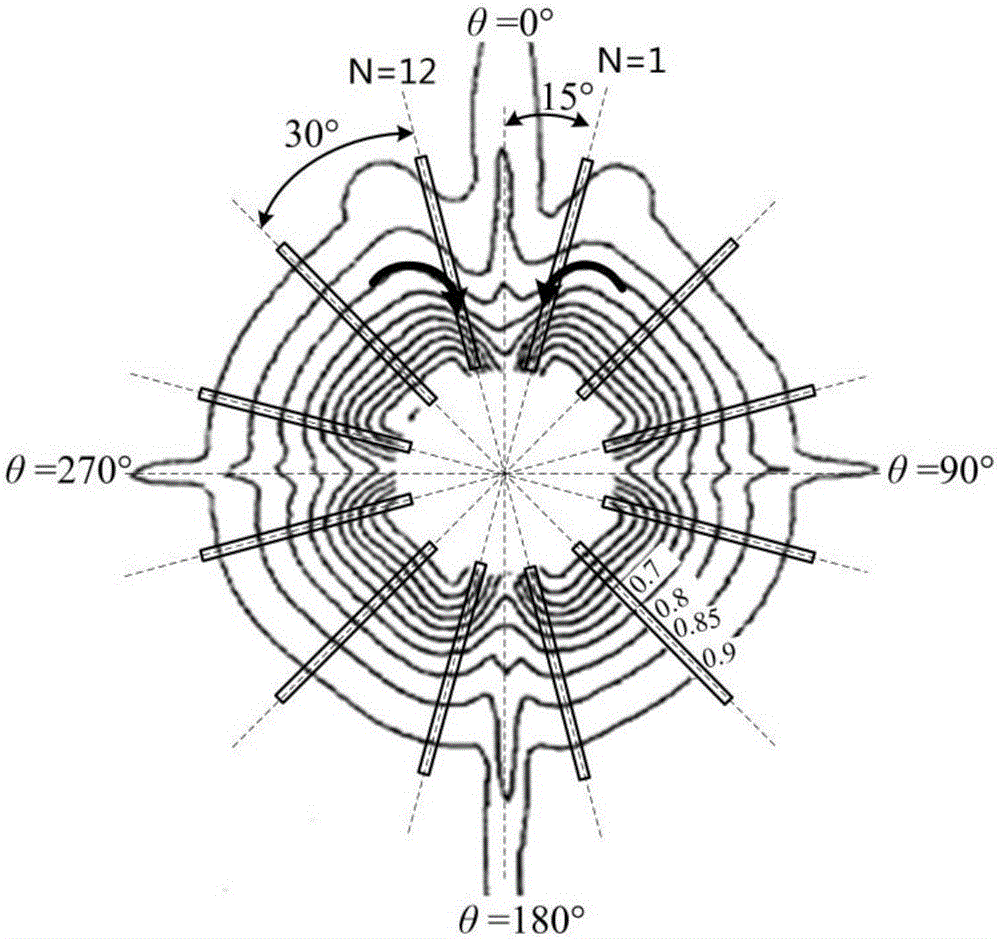

[0049] pass below Figure 1 to Figure 7 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0050] The flow chart of the hydraulic model design method of the pump-jet thruster designed by the present invention is as follows: Figure 7 as shown,

[0051] Step S1, performing type selection and design of the hydraulic parameters of the pump fluid channel according to the design requirements;

[0052] When selecting and designing, according to the theory of ship water jet propulsion, the five parameters of pump jet cascade channel head, flow rate, outlet area, specific speed and suction specific speed parameters are determined according to the rapidity requirements.

[0053] Step S2, determine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com