Connection device of optical-fiber composite overhead insulated bunched cable and usage method

A bundled cable and overhead insulation technology, applied in the electric power field, can solve the problems of high maintenance costs, achieve low melting point, save cable resources, and prevent short-circuit or burn accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

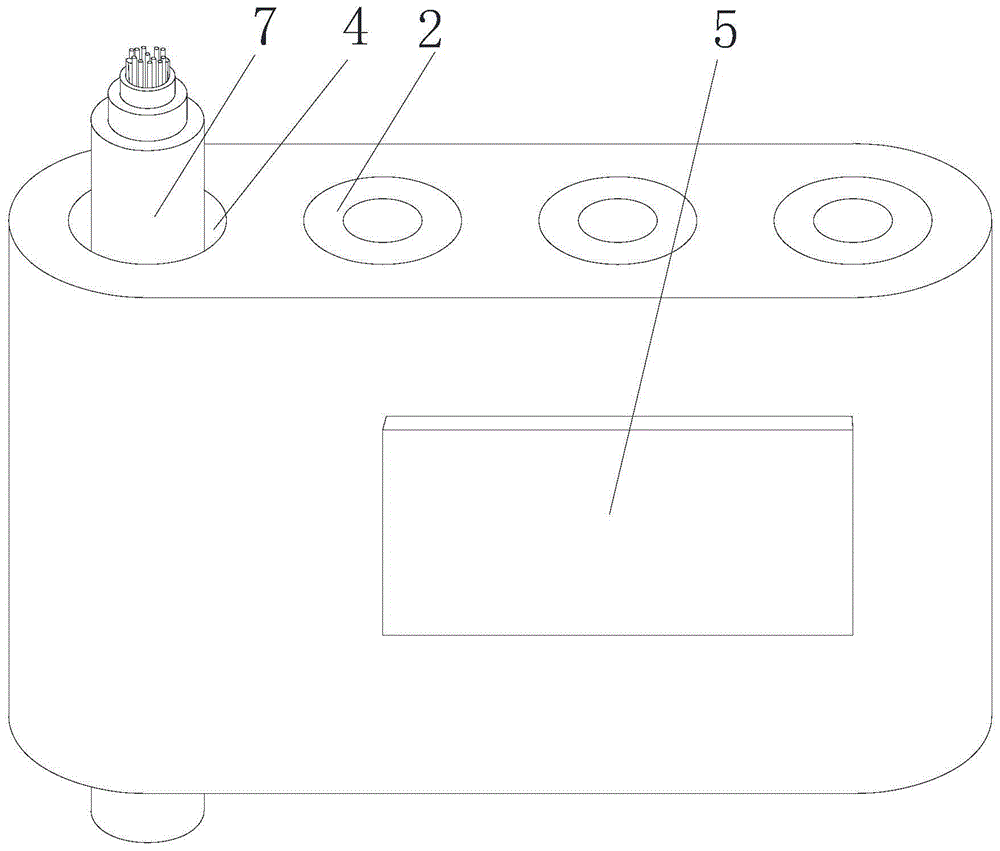

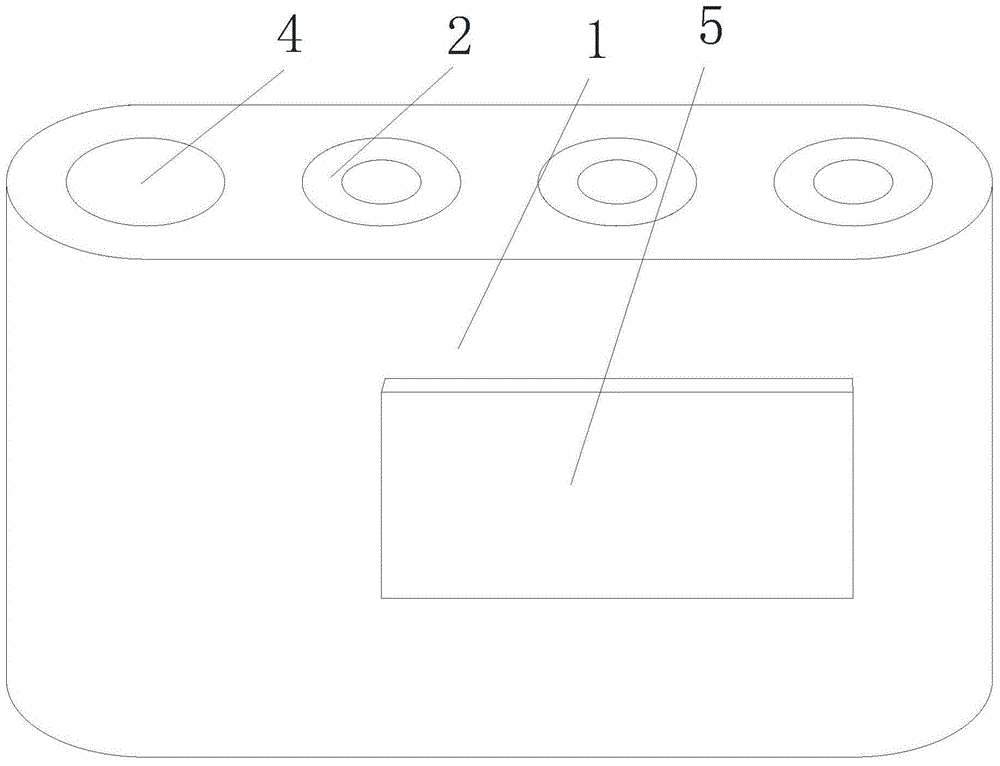

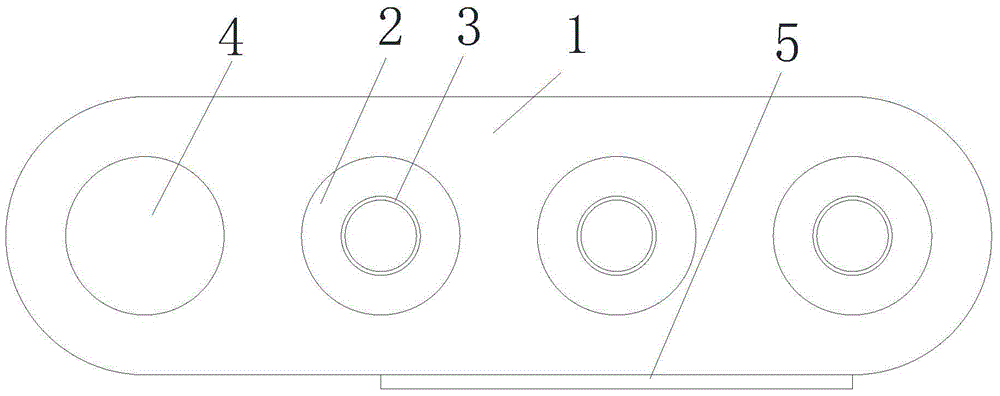

[0026] See Figure 1-4 , the connection device of optical fiber composite overhead insulated bundled cables, including an insulating body 1, a plurality of mutually isolated through holes are arranged on the insulating body 1, and a conductive tube 2 is arranged in each through hole, and the two ends of the conductive tube 2 are flush with the through holes, and conduct electricity. The tube 2 is not exposed outside the insulating body 1 to prevent leakage accidents or short-circuit faults caused by contact with external objects. On this basis, the conductive tube 2 is as long as possible to increase the contact area between the conductive tube 2 and the battery core 8 to reduce resistance. , the conductive tube 2 and the insulating body 1 are separable structures, and the matching conductive tube 2 can be replaced according to the cells 8 of different cross-sectional areas, so that the inner wall of the conductive tube 2 and the cell 8 are interference fit to maximize The con...

Embodiment 2

[0030] See Figure 5, the connection device of optical fiber composite overhead insulated bundled cables, including an insulating body 1, a plurality of mutually isolated through holes are arranged on the insulating body 1, and a conductive tube 2 is arranged in each through hole, and the two ends of the conductive tube 2 are flush with the through holes, and conduct electricity. The tube 2 is not exposed outside the insulating body 1 to prevent leakage accidents or short-circuit faults caused by contact with external objects. On this basis, the conductive tube 2 is as long as possible to increase the contact area between the conductive tube 2 and the battery core 8 to reduce resistance. , the conductive tube 2 and the insulating body 1 are separable structures, and the matching conductive tube 2 can be replaced according to the cells 8 of different cross-sectional areas, so that the inner wall of the conductive tube 2 and the cell 8 are interference fit to maximize The contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com