Overhead wire for tram

An overhead wire and wire technology, applied in the wire field, can solve the problems of high wire cost, low technical difficulty, and high technical difficulty, and achieve the effects of low cost, low technical difficulty and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings:

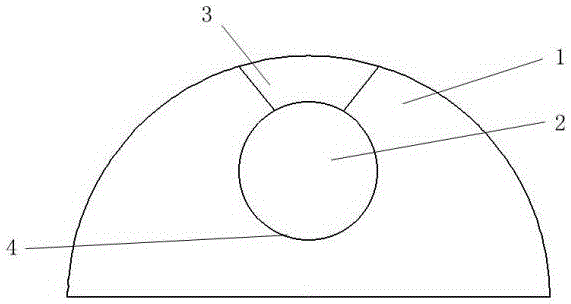

[0021] like figure 1 As shown, the cross-section of the electric wire 1 is semicircular, the circular arc faces upward, the middle part has a groove, and the lower end is a plane, and the power-taking device is in contact with the plane to increase the contact area and reduce power consumption. The material of the electric wire 1 is copper; The wire core 2 is embedded in the groove in the middle of the wire 1, and its material is stainless steel wire with good corrosion resistance and oxidation resistance. The diameter of the wire core 2 is 5 mm; there is a wire 1 above the wire core 2 The bell-shaped opening 3 is easy to connect with the overhead line pole. The width of the upper opening of the opening 3 is 5mm, the width of the lower opening of the opening 3 is 2.5mm, the height of the opening 3 is 3mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Catchy width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com