Motor, transformer core and manufacturing method thereof

A technology for transformers and motors, which is applied to parts, circuits, and electrical components of transformers/inductors. It can solve problems such as poor magnetic permeability eddy current loss, reduced core efficiency, and reduced magnetic performance of the core, so as to ensure dimensional accuracy and reduce The effect of high loss and magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

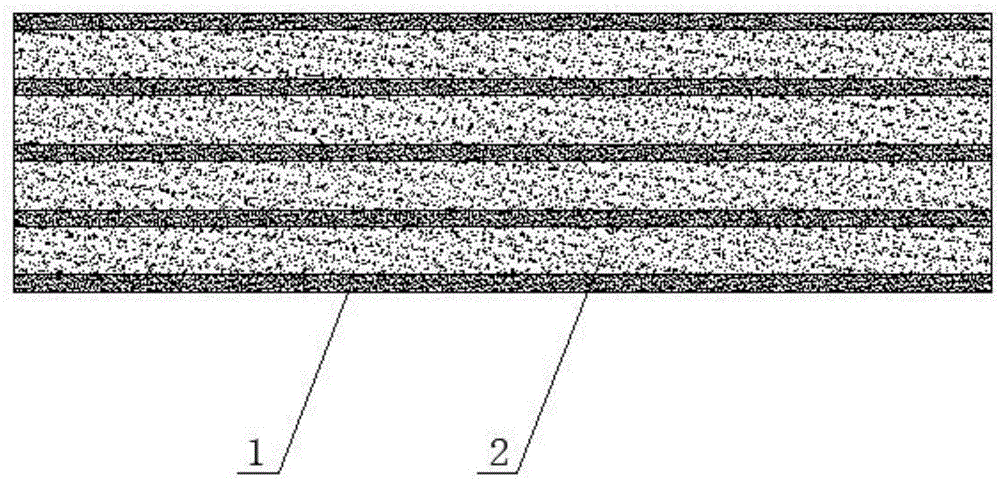

[0030] As shown in the figure, the motor iron core and the transformer iron core are composed of multi-layer dense solid layers 2 of magnetically conductive metal powder and dense solid layers 1 of multi-layer ceramic insulating powder. The dense solid layers 2 of magnetically conductive metal powder and ceramic insulating powder The dense solid layer 1 is distributed from bottom to top at intervals. In this embodiment, the number of layers of the dense solid layer 2 of magnetically conductive metal powder is 4 layers, and the number of layers of dense solid layer 1 of ceramic insulating powder is 5 layers. The top layer is a dense solid layer 1 of ceramic insulating powder, the thickness of the dense solid layer 2 of magnetically permeable metal powder is 0.1mm-0.8mm, and the thickness of the dense solid layer 1 of ceramic insulating powder is 0.02mm-0.1mm.

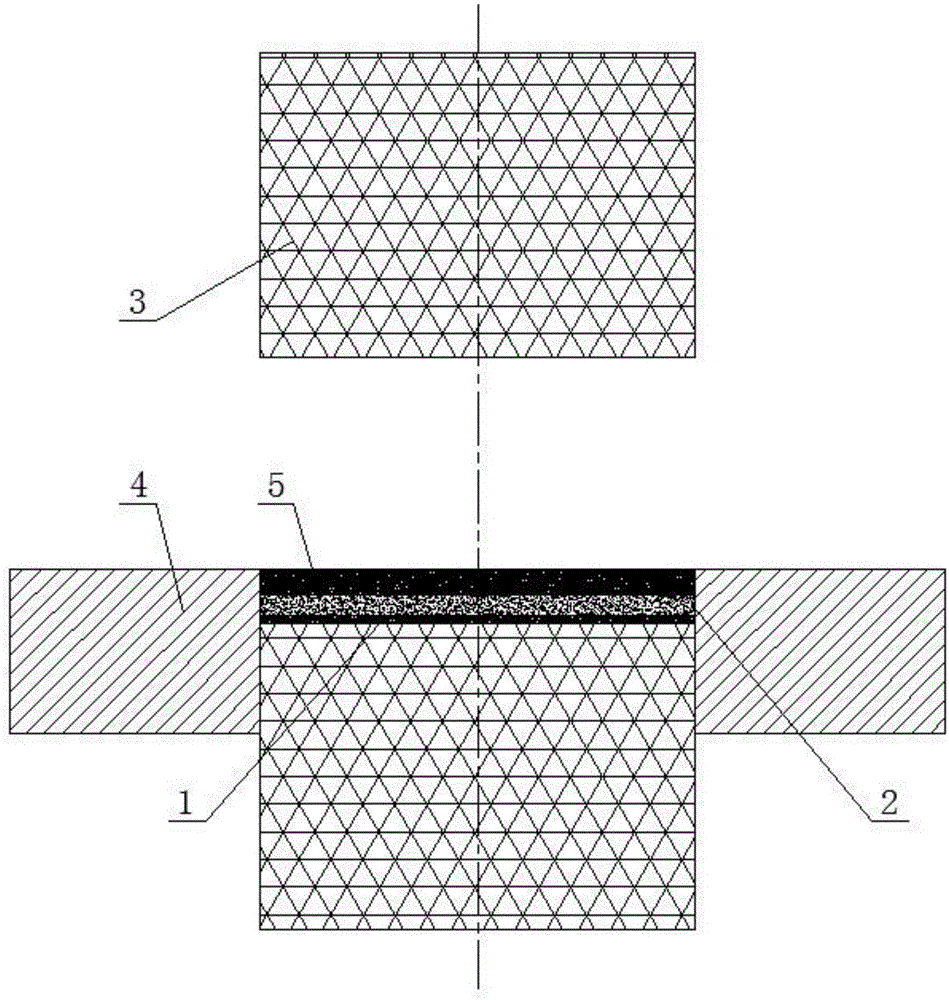

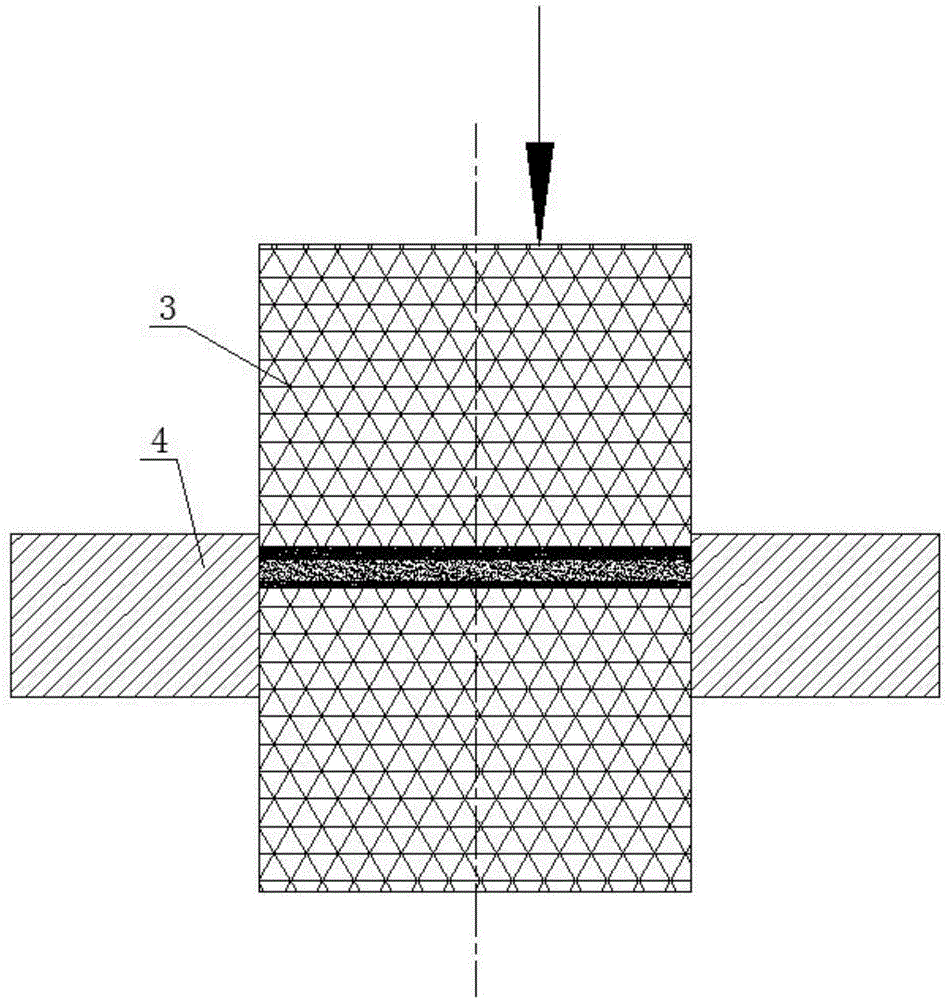

[0031] The manufacturing method of the motor iron core and the transformer iron core comprises the following steps:

...

Embodiment 2

[0038] The motor iron core and the transformer iron core are alternately composed of multi-layer dense solid layers 2 of magnetically conductive metal powder and dense solid layers 1 of multi-layer ceramic insulating powder, and the dense solid layers 2 of magnetically conductive metal powder and dense solid layers 1 of ceramic insulating powder are composed of Distributed at intervals from bottom to top, in this embodiment, the number of layers of the dense solid layer 2 of magnetically conductive metal powder is 10 layers, the number of layers of dense solid layer 1 of ceramic insulating powder is 11 layers, and the bottom and top layers of the iron core are both ceramic insulation Powder dense solid layer 1, the thickness of ceramic insulating powder dense solid layer 1 is 0.03mm, the working pressure of the press is 700MPa, the thickness of magnetically conductive metal powder dense solid layer 2 is 0.1mm, the working pressure of the press is 700MPa, the finished product Th...

Embodiment 3

[0040] The motor iron core and the transformer iron core are alternately composed of multi-layer dense solid layers 2 of magnetically conductive metal powder and dense solid layers 1 of multi-layer ceramic insulating powder, and the dense solid layers 2 of magnetically conductive metal powder and dense solid layers 1 of ceramic insulating powder are composed of Distributed at intervals from bottom to top, in this embodiment, the number of layers of the dense solid layer 2 of magnetically conductive metal powder is 3 layers, the number of layers of dense solid layer 1 of ceramic insulating powder is 4 layers, and the bottom and top layers of the core are both ceramic insulating Powder dense solid layer 1, the thickness of ceramic insulating powder dense solid layer 1 is 0.1mm, the working pressure of the press is 800MPa, the thickness of magnetically conductive metal powder dense solid layer 2 is 0.8mm, the working pressure of the press is 800MPa, the finished product The height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com