Method for improving grain boundary phase of neodymium iron boron

A grain boundary phase, neodymium iron boron technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of increased cost, uneven metal distribution, complex process, etc., to achieve enhanced coercive force and simplified doping process, the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Metal Sn is supported on Cu powder by cathode sputtering method (according to the mass ratio Sn:Cu=1:3), doped (Pr 0.25 Nd 0.75 ) 2.2 (Fe 14 Nb 0.2 al 0.3 ) In the B magnet, the particle size after mixing is about 12 microns, and the doping amount is 0.3%wt. The final performance of the magnet is: Br=13.8Gs, Hcj=15.7kOe, (BH) max = 45.7 MOeGs.

Embodiment 2

[0036] Mix metal Sn (melting point is about 231.9°C) and copper powder (melting point is about 1083.4°C) and heat to 400°C, Sn is melted and mixed with copper powder evenly, then use spray technology (gas atomization method) to prepare Sn / Cu Composite alloy powder, its particle size is about 22 microns (by mass ratio Sn: Cu=1: 1), doped with (Pr 0.25 Nd 0.75 ) 2.2 (Fe 14 Nb 0.2 al 0.3 ) In the B magnet, the doping amount is 0.5%wt. The final performance of the magnet is: Br=13.6Gs, Hcj=16.2kOe, (BH) max = 44.7 MOeGs. .

Embodiment 3

[0038] Metal magnesium (boiling point: about 1090°C) is heated by vacuum evaporation on copper powder (melting point: about 1083.4°C) and evaporated onto copper powder to prepare Mg / Cu composite alloy powder with a particle size of about 16 Micron (according to the mass ratio Mg: Cu = 1: 3), doped (Pr 0.25 Nd 0.75 ) 2.2 (Fe 14 Nb 0.2 al 0.3 ) In the B magnet, the doping amount is 0.2%wt. The final performance of the magnet is: Br=13.8Gs, Hcj=16.4kOe, (BH) max = 45.9 MOeGs.

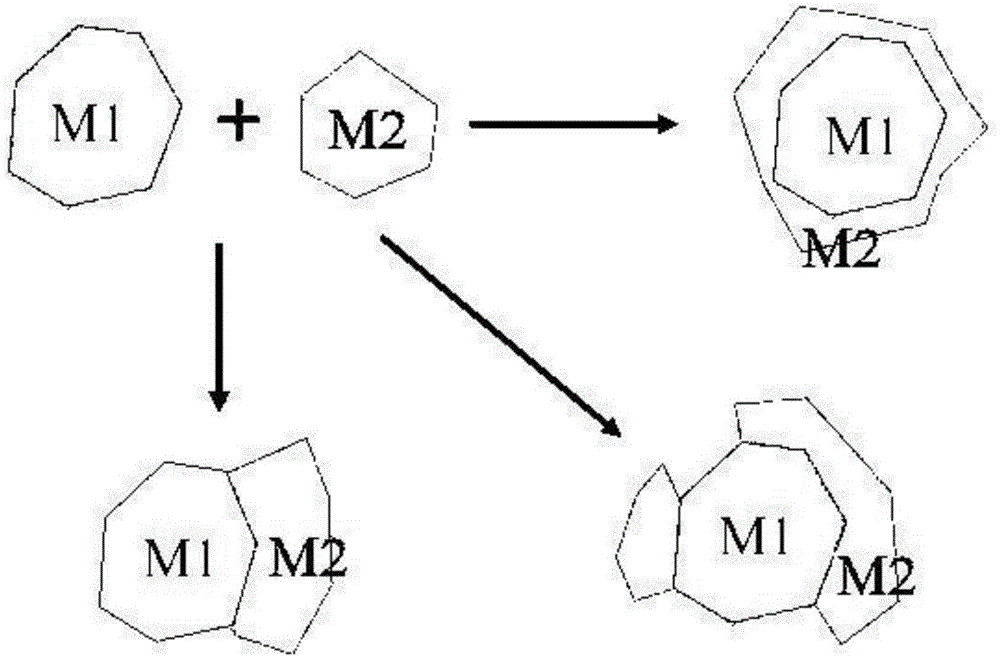

[0039] Through comparative examples, Example 1, Example 2 and Example 3, by loading one metal or compound on the powder of another metal or compound, it is made into a fully wrapped, or partially wrapped, or adhered Type composite mixed alloy powder, and then mixed into the main phase alloy powder by the mixed alloy method, also achieve the effect of doping two or more metal elements in the grain boundary, effectively improving the performance of the magnet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com