Method for the temperature control of a traction battery arranged in a vehicle during a charging process at a charging station, and charging station for performing such a method

A charging process, charging station technology, applied in battery/battery traction, charging stations, electric traction, etc., to achieve weight reduction, cost reduction, and prevent severe heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

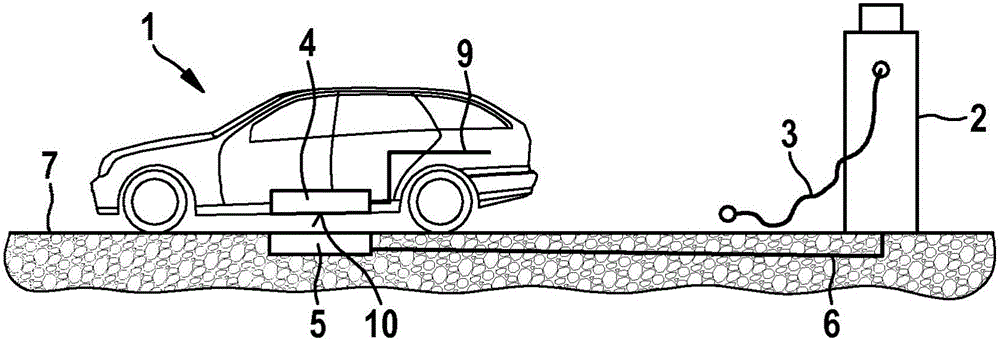

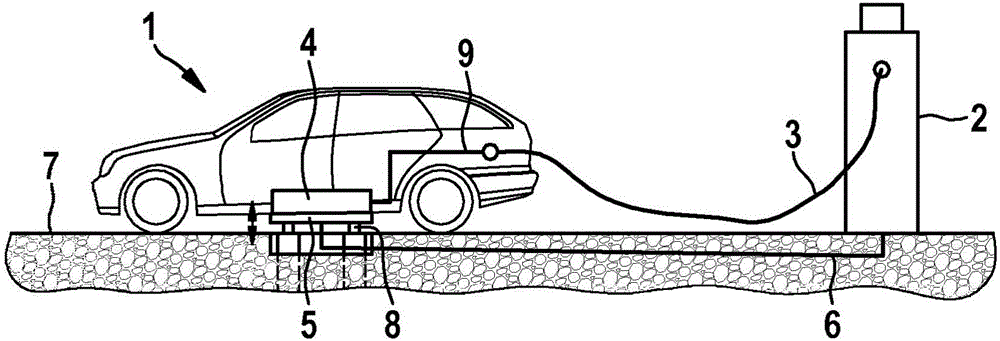

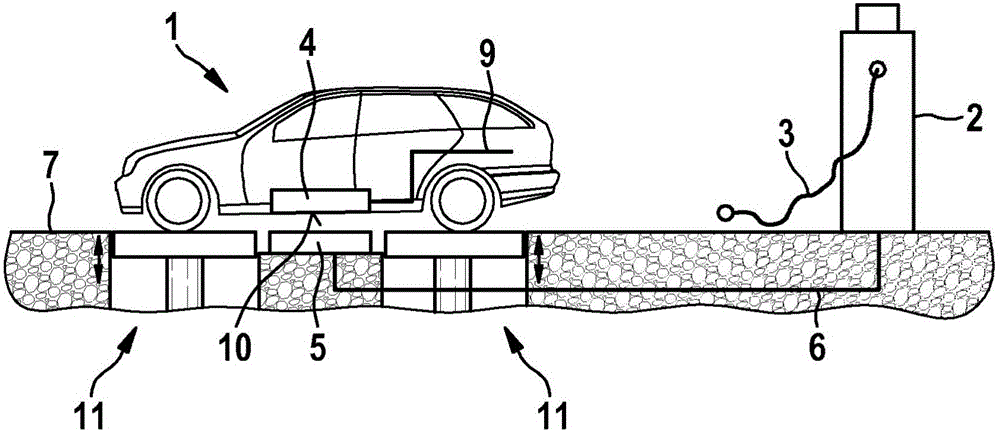

[0040] exist figure 1 An electric vehicle 1 with a traction battery 4 is shown in FIG. In addition, in figure 1 A charging station 2 is shown in , which in particular enables rapid charging of the traction battery 4 of the vehicle 1 . In this case, charging station 2 has connecting lines 3 for electrically conductively connecting charging station 2 to traction battery 4 . Furthermore, the charging station 2 includes a cooling body 5 sunk into the ground 7 for cooling the traction battery arranged in the vehicle to be charged during the charging process at the charging station 2 . Here, the cooling body 5 is cooled by the cooling medium (in figure 1 not explicitly shown) flow through. In this case, the cooling body 5 communicates with the cooling device provided on the charging station 2 (in the figure 1 not explicitly shown in ), wherein the cooling device regulates the temperature of the cooling medium to a predetermined theoretical value.

[0041] In addition, the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com