Thermal paste for improving thermal contacts

a thermal contact and thermal paste technology, applied in indirect heat exchangers, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of poor conformability and spreadability, low thermal conductivity, and deformation when exposed to humidity, and achieve the effect of improving the thermal conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Paste Formulations

[0047] The polyethylene glycol, HO(CH2CH2O)11H, (“PEG”) used as an organic vehicle was PEG 400 (EM Science, Gibbstown, N.J.). It had a molecular weight of 400 amu. It was a liquid at room temperature and optionally contained ethyl cellulose (Sigma Chemical Co., St. Louis, Mo.) at either 3 or 5 vol. %. The ethyl cellulose was a white powder that was dissolved in the vehicle. It served to improve the dispersion and suspension of the solids in the pastes.

[0048] The other organic vehicle used was di(ethylene glycol) butyl ether (Aldrich Chemical Co., Inc., Milwaukee, Wis.). It optionally contained ethyl cellulose (Sigma Chemical Co., St. Louis, Mo.) at 10, 20, 30 or 40 vol. %.

[0049] The carbon black used was a type for electrical conductivity and easy dispersion (Vulcan XC72R GP-3820; Cabot Corp., Billerica, Mass.). It consisted of porous agglomerates of carbon particles of particle size 30 nm, density 1.7-1.9 g / cm3, nitrogen specific surface area 254...

example 2

Thermal Contact Conductance Measurement

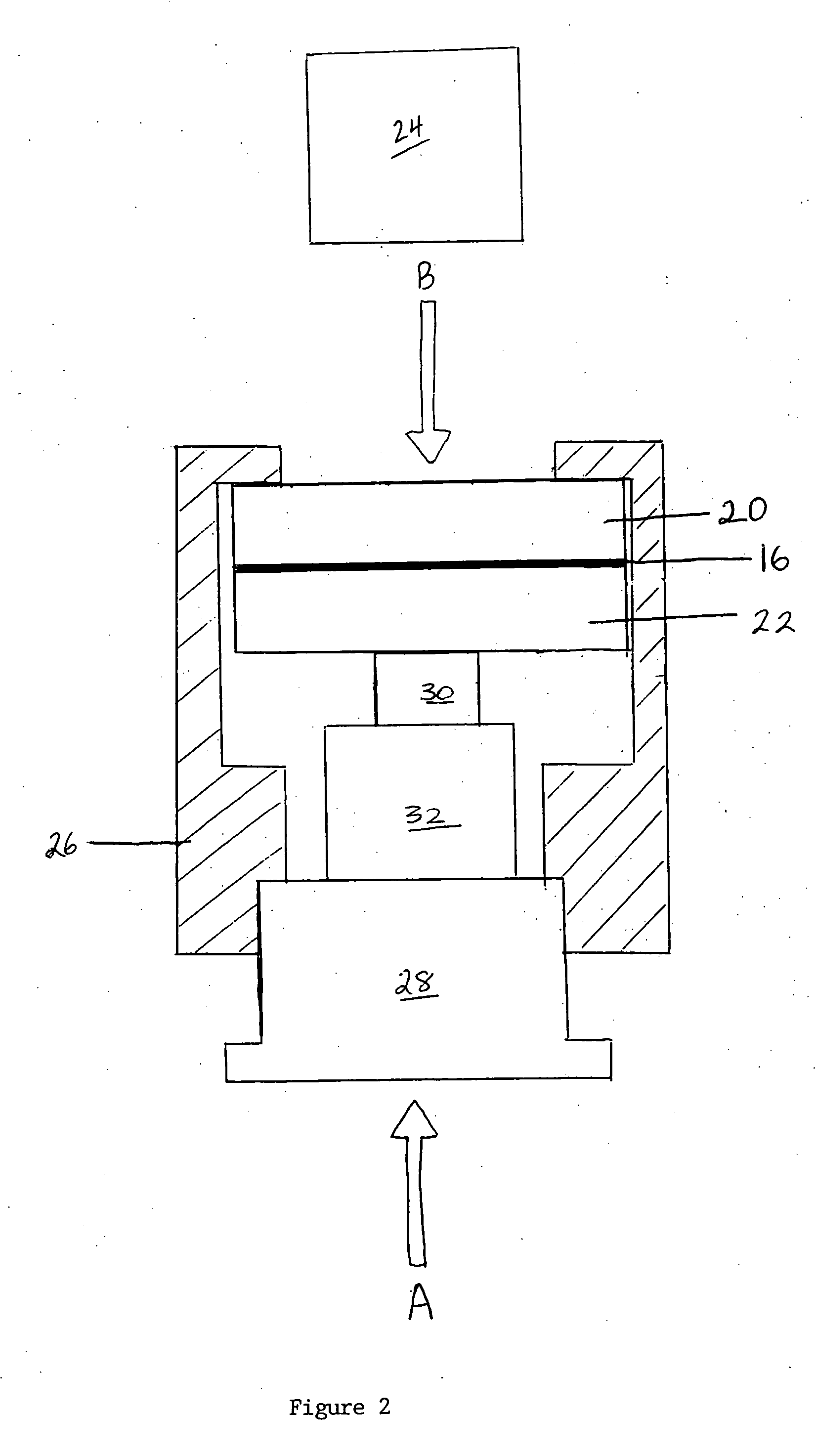

[0052] As generally depicted in FIG. 2, a layer of a thermally conductive paste 16 (or solder) was sandwiched between the flat surfaces of two copper disks 20,22 (both surfaces of each disk having been mechanically polished by using 0.05 μm alumina particles), which had diameter 12.6 mm and thickness of 1.16 mm for one disk and 1.10 mm for the other disk. The thermal contact conductance between two copper disks with and without a layer of thermally conductive paste 16 (or solder) was measured using the transient laser flash method. Xu et al., J. Electron. Pkg. 124:188-191 (2002); Xu et al., J Electron. Pkg. 122:128-131 (2000); Parker et al., J. Appl. Phys. 32:1679-1683 (1961); Inoue et al., Yosetsu Gakkai Ronbunshu / Quarterly J Jap. Welding Soc., 6:130-134 (1988), which are hereby incorporated by reference in their entirety.

[0053] The pressure on the sandwich was controlled at 0.46, 0.69 and 0.92 MPa (depicted in FIG. 2 as arrow A). This is be...

example 3

Viscosity Testing

[0059] The viscosity of the formulations was measured by using a viscometer (Brookfield Engineering Laboratories, Inc., Middleboro, Mass., Model LVT Dial-Reading Viscometer, with Model SSA-18 / 13R Small Sample Adaptor).

PUM

| Property | Measurement | Unit |

|---|---|---|

| vol. % | aaaaa | aaaaa |

| vol. % | aaaaa | aaaaa |

| vol. % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com