lng ship or lpg ship

A technology for LNG ships and hulls, applied in the directions of ship hulls, ship parts, ship construction, etc., can solve problems such as damage to membranes or insulation parts, and achieve the effect of reducing material costs and large tank volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Embodiments of the present invention will be described below with reference to the drawings.

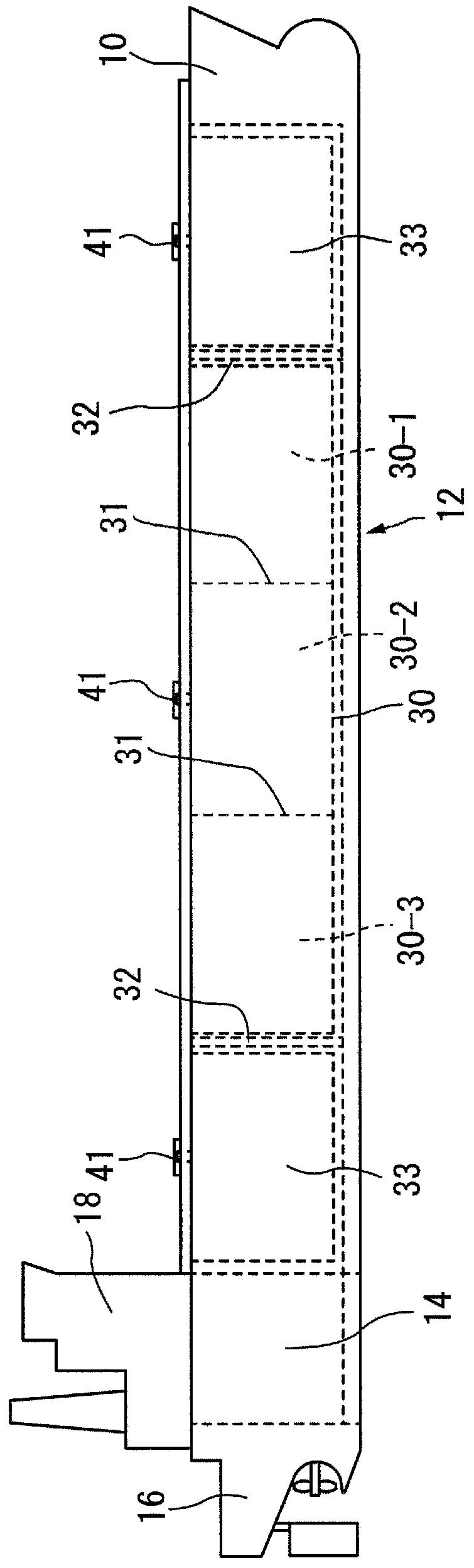

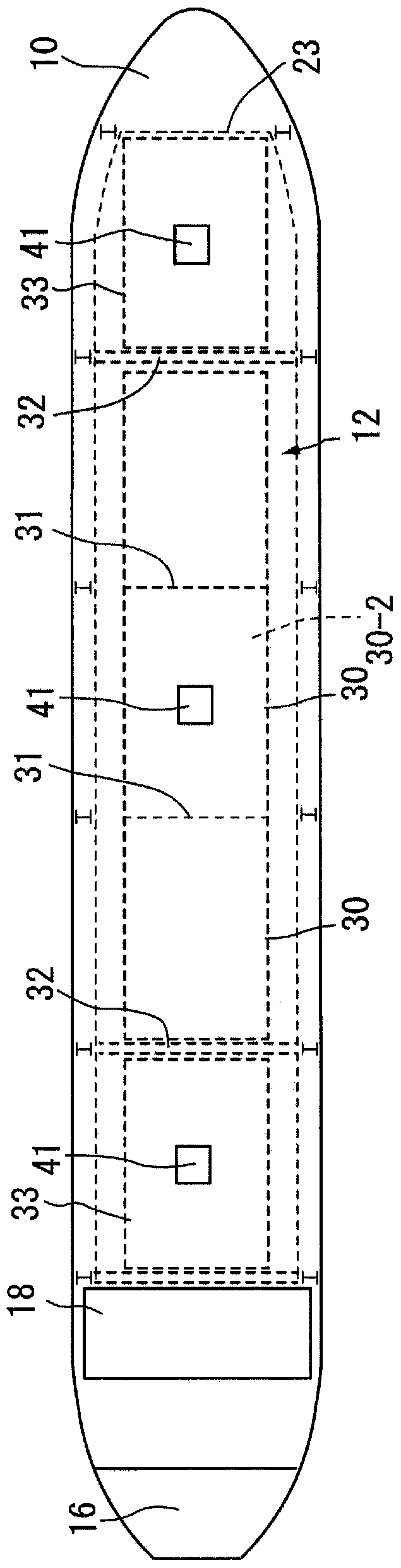

[0076] Such as figure 1 and figure 2 As shown, the LNG ship is sequentially connected from the front with the bow 10 , the tank partition 12 , the machinery room 14 and the stern 16 , and above the machinery room there is a living area 18 and even a wheelhouse 20 . The tank section is divided into a plurality of sections by transverse partition walls 32 .

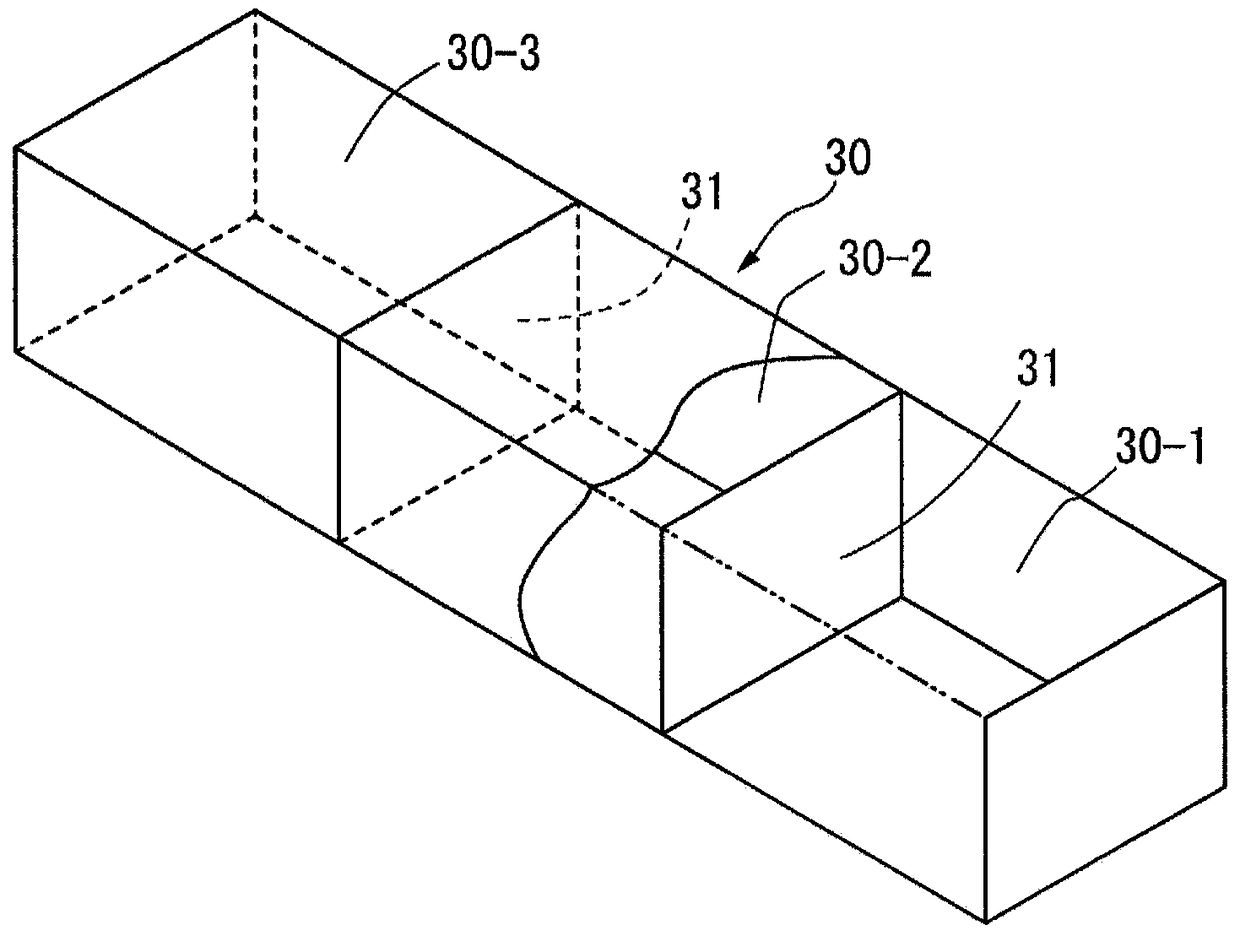

[0077] In the present invention, it is an LNG ship having a structure in which a substantially square independent tank 30 is installed in the hold without being integrated with hull (double hull) structural members 36 and 35 .

[0078] In addition, supports 36 , 36 .

[0079] In the present invention, at least a part of the tank group is designed as an independent rectangular long tank 30 that is longer in the ship's length direction than in the ship's width direction, and the long tank 30 is arranged in the cabin alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com