Fibre sensor assembly

An optical fiber sensor, optical fiber technology, applied in the field of bearings, can solve the problem of thermal damage of optical fiber sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

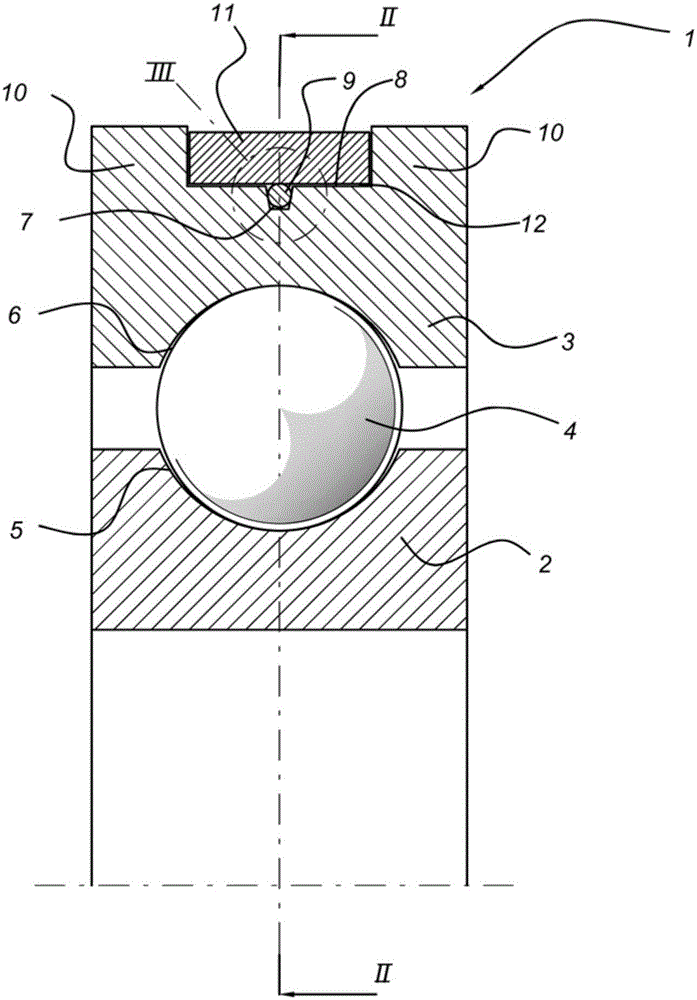

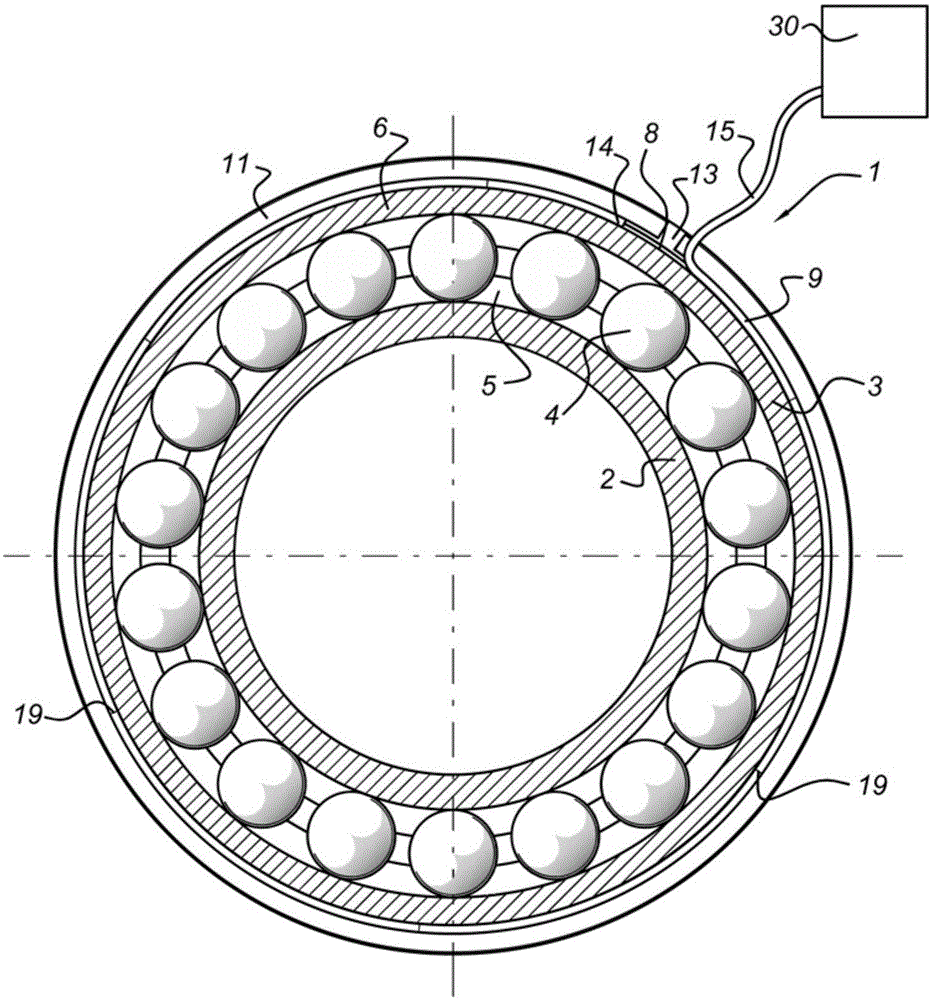

[0026] figure 1 An axial cross-section of the bearing 1 is shown, comprising an inner bearing ring 2 with inner raceways 5 and an outer bearing ring 3 with outer raceways 6 . Rolling elements 4 are arranged between the inner and outer rings 2, 3 so that the inner and outer bearing rings 2, 3 can rotate relative to each other. The rolling elements 4 are located between the inner and outer raceways 5 , 6 .

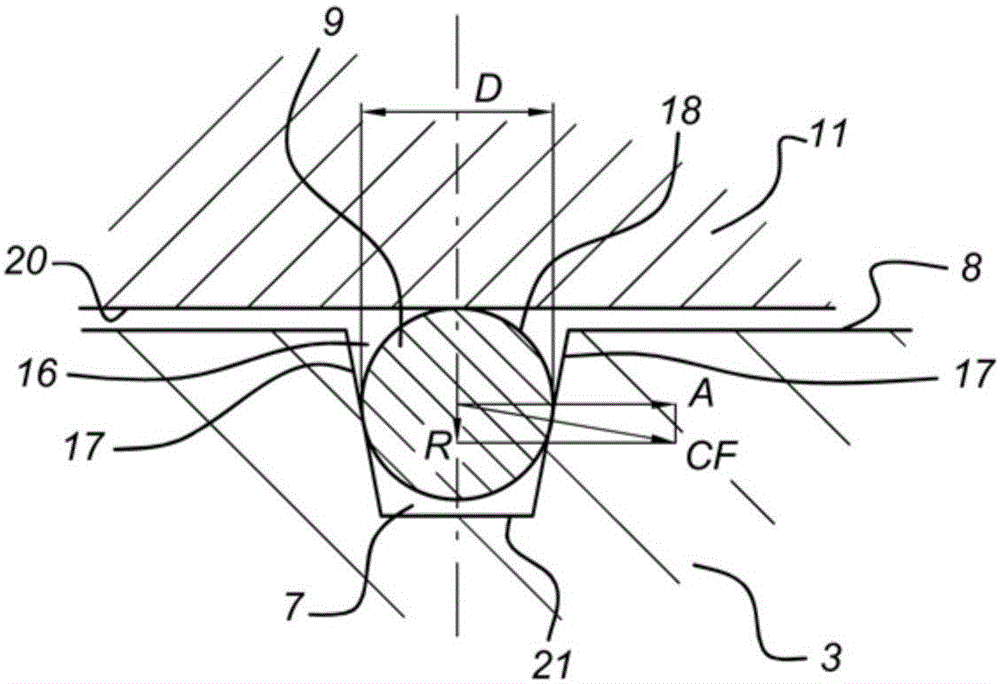

[0027]The grooves 7 are provided on the outer surface 8 of the outer bearing ring 3 . The groove 7 accommodates a fiber optic sensor 9, which includes an optical fiber. In turn, the grooves 7 are provided with channels 12 . The channel 12 is shaped as a recess between the two side walls 10 which form an increase in the thickness of the outer bearing ring 3 .

[0028] The fiber optic sensor 9 is accommodated in the groove 7 and is connected to the outer bearing ring by means of a clamping ring 11 . The clamping ring 11 is accommodated in the channel 12 . The clamping ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com