Purging inspection device of continuous casting three-machine three-flow spraying system and purging inspection method

A spray system and continuous casting technology, which is applied in the field of inspection and purging devices of the three-machine three-stream spray system in continuous casting, can solve problems such as out-of-roundness, no-water discharge from the nozzle, and problems with the appearance quality of the slab, and achieve less clogging, The effect of reducing the cost of test run and avoiding equipment freezing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

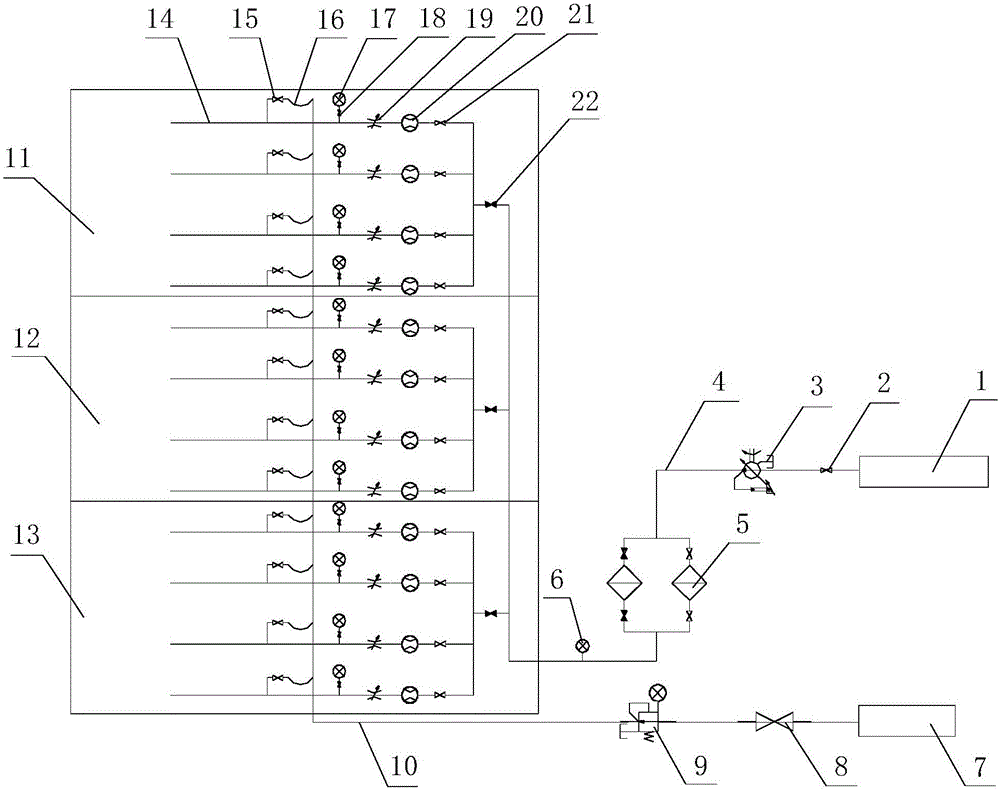

[0025] see figure 1 , a continuous casting three-machine three-flow spray system inspection and purging device, including a secondary cooling water main pipeline 4, a nitrogen main pipeline 10, a first-class spraying system 11, a second-flow spraying system 12 and a third-flow spraying system 13; the secondary cooling water One end of the main pipe 4 is connected to the secondary cooling water pipe network 1, and the other end is respectively connected to the first-class spraying system 11, the second-stream spraying system 12 and the third-stream spraying system 13 through three secondary cooling water branch pipes. The secondary cooling water inlet valve 2, the secondary cooling water booster pump 3, the secondary cooling water filter 5 and the secondary cooling water inlet pressure gauge 6, the secondary cooling water branch pipeline is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com