Preparation method for man-made quartz-stone corrugated plate and screw extrusion machine

A technology of screw extruder and artificial quartz stone, which is applied in the field of preparation of screw extruder and artificial quartz stone water pattern plate, which can solve the problem of no artificial quartz stone water pattern plate and artificial quartz stone water pattern plate. , It is difficult to solve problems such as batch stability and consistency, and achieve the effect of high impact resistance, not easy to deform and break, and batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

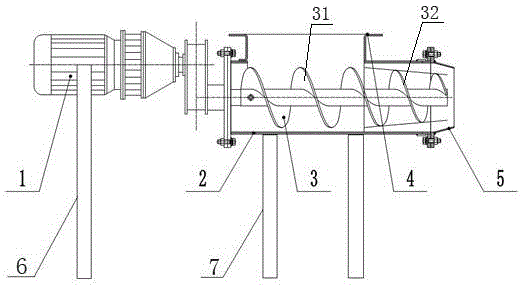

[0033] A screw extruder, comprising a cylinder body 2, a bracket 7 is arranged under the cylinder body 2, a motor 1 is arranged outside the cylinder body 2, a bracket 6 is arranged under the motor 1, a feed inlet is arranged above the cylinder body 2, and the cylinder body 2 The right end is provided with an extrusion outlet 5 with a diameter smaller than that of the cylinder body 2, and the cylinder body 2 is provided with a screw conveying shaft 3, and one end of the screw conveying shaft 3 extends out of the cylinder body 2 and is connected with the motor 1 through a coupling , the premixed material added from the feeding port 4 is extruded from the extruding discharge port 5 under the extrusion of the screw conveying shaft 3, forming a material with water grain texture.

[0034] The screw conveyor shaft 3 includes an isometric shaft section 31 and a tapered shaft section 32 whose diameter gradually decreases. The isometric shaft section 31 is located at a corresponding posi...

Embodiment 2

[0044] A preparation method of artificial quartz stone water pattern plate, comprising the following steps:

[0045] (1) Ingredients: Weigh each raw material according to the following parts by weight: 70 parts of quartz sand of 8~120 mesh, 20 parts of quartz powder of 300~500 mesh, 0.5 part of benzoyl peroxide, 1.5 parts of silane coupling agent, 11 parts of resin part and 0.05 part of toner;

[0046] (2) Mixing: Send each raw material into the mixer for premixing to obtain a premix;

[0047] (3) Extrusion: feed the premixed material into the screw extruder described in Example 1, the premixed material forms an extruded material under the action of the screw conveying shaft 3, and the extruded material is discharged from the extrusion outlet 5, The frequency of the screw extruder is 12r / min, and the extrusion time is 15min;

[0048] (4) Cloth: convey the extruded material to the cloth bucket for automatic cloth;

[0049] (5) Pressing: transport the clothed material to the ...

Embodiment 3

[0053] A preparation method of artificial quartz stone water pattern plate, comprising the following steps:

[0054] (1) Ingredients: Weigh each raw material according to the following parts by weight: 60 parts of quartz sand of 8~120 mesh, 30 parts of quartz powder of 300~500 mesh, 0.3 part of methyl ethyl ketone peroxide, 2.5 parts of silane coupling agent, 9 parts of resin and 0.1 parts of toner;

[0055] (2) Mixing: Send each raw material into the mixer for premixing to obtain a premix;

[0056] (3) Extrusion: feed the premixed material into the screw extruder described in Example 1, the premixed material forms an extruded material under the action of the screw conveying shaft 3, and the extruded material is discharged from the extrusion outlet 5, The frequency of the screw extruder is 12r / min, and the extrusion time is 10min;

[0057] (4) Cloth: convey the extruded material to the cloth bucket for automatic cloth;

[0058] (5) Pressing: transport the clothed material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com