Cushion structure used for inside of package box and package structure

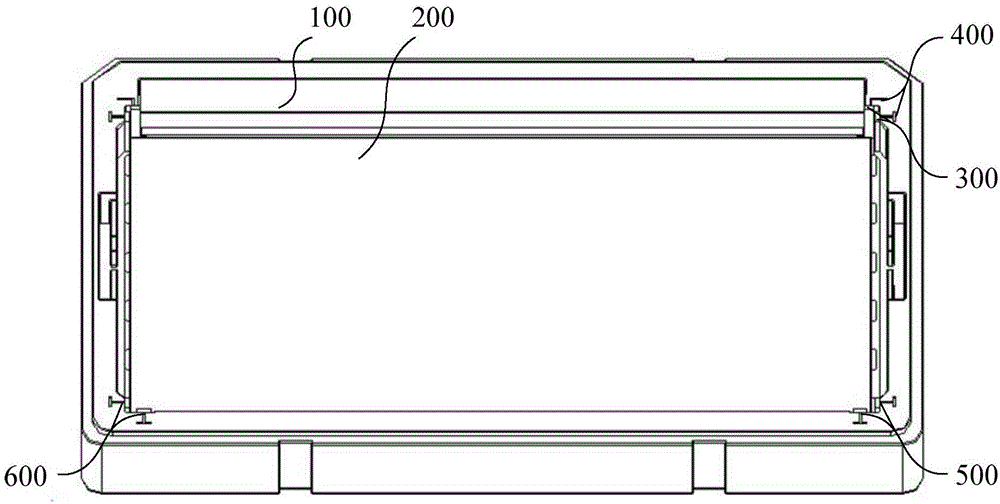

A technology of buffer structure and packaging structure, applied in packaging, packaging food, packaging protection and other directions, can solve the problems of only overall replacement, high use cost, and contamination of liquid crystal products, and achieves the effect of good cooperation firmness and low use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

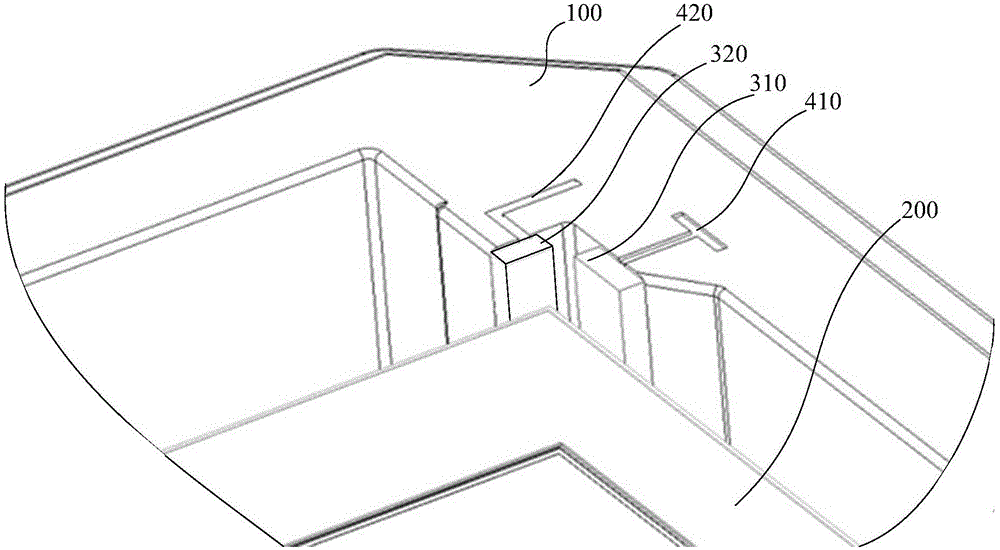

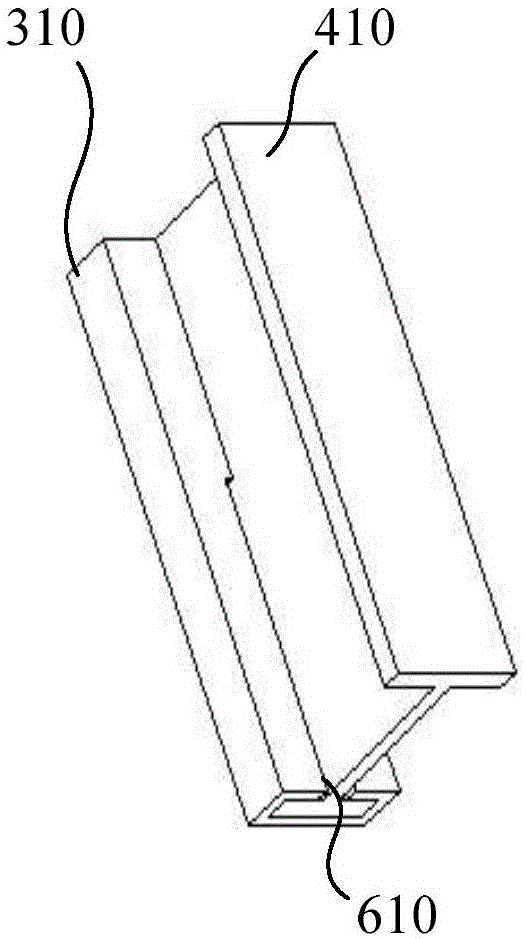

[0047] Method 1: If image 3 with Figure 4 As shown, the first component 310 is a cuboid structure formed by the cooperation of side plates 3103 and 3105 arranged in parallel, side plates 3102, 3104 and side plates 3101 arranged in parallel, wherein side plates 3103, 3102 , side plate 3105 and side plate 3104 are vertically connected successively, and side plate 3103, side plate 3102, side plate 3105 and side plate 3104 are vertically connected with side plate 3101, and there is a slot 510 on the side plate 3103.

[0048] Method 2: If Image 6 with Figure 7 As shown, the first component 320 is a cuboid structure formed by the cooperation of side plates 3201 and 3204 arranged in parallel, side plates 3202 and 3205 arranged in parallel, and side plates 3203, wherein side plates 3201, 3202 , side plate 3204 and side plate 3205 are vertically connected successively, and side plate 3201, side plate 3202, side plate 3204 and side plate 3205 are vertically connected with side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com