Automatic conveying type batching shaft bracket

A technology of automatic transportation and cloth reeling, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc. It can solve the problems of increasing labor intensity, fabric damage, and waste of human resources, so as to reduce labor intensity and improve Quality, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

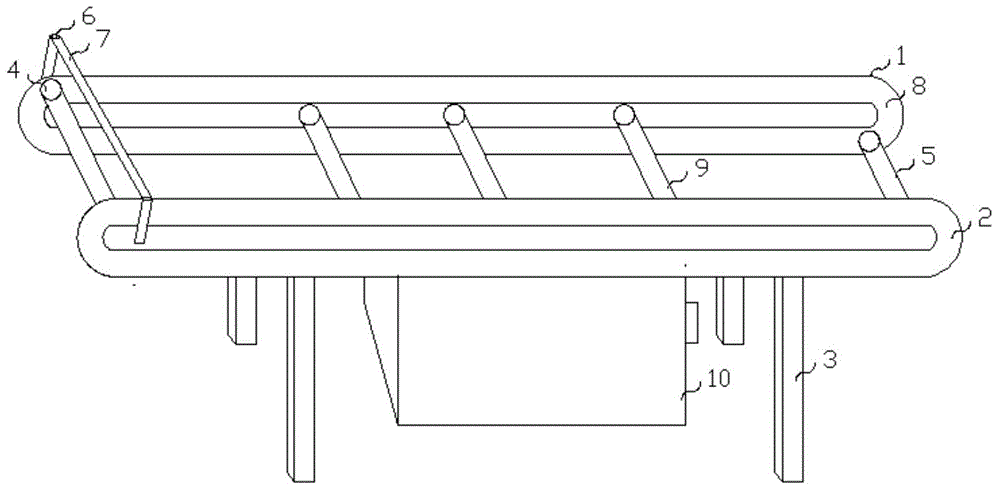

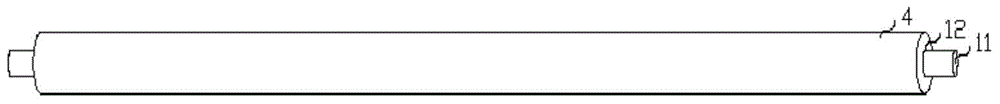

[0015] Example: such as Figure 1-2 As shown, the present invention is an automatic transport reel frame, comprising a first reel frame 1 and a second reel frame 2, the first reel frame 1 and the second reel frame 2 are connected by a number of connecting columns 9, and the bottoms of the first cloth reel frame 1 and the second cloth reel frame 2 are provided with brackets 3, and the first cloth reel frame 1 and the The inner surface of the second cloth winding frame 2 is provided with a slide rail 8, and the slide rail 8 is connected with the first cloth winding shaft 4 and the second cloth winding shaft 5 through a pulley 11, and the first cloth winding shaft 4 and the second cloth winding shaft 5 are connected with the motor 10 through internal lines.

[0016] Two connectors 6 are provided on the outer surfaces of one end of the first cloth roll frame 1 and the second cloth roll frame 2, and the cloth roll inlet shaft 7 is connected through the connectors 6, and the cloth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com