Method of preparing Cr<3+>-doped CoFe2O4 high-density magnetic-recording material

A magnetic recording, high-density technology, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preparation of Cr 3+ Doped CoFe 2 o 4 The concrete steps that the method for high-density magnetic recording material adopts are as follows:

[0020] Step 1. Weigh an appropriate amount of NaOH particles and dissolve them in deionized water to obtain a clear solution of NaOH as a precipitant. The concentration of the NaOH solution is 0.4mol / L-0.6mol / L;

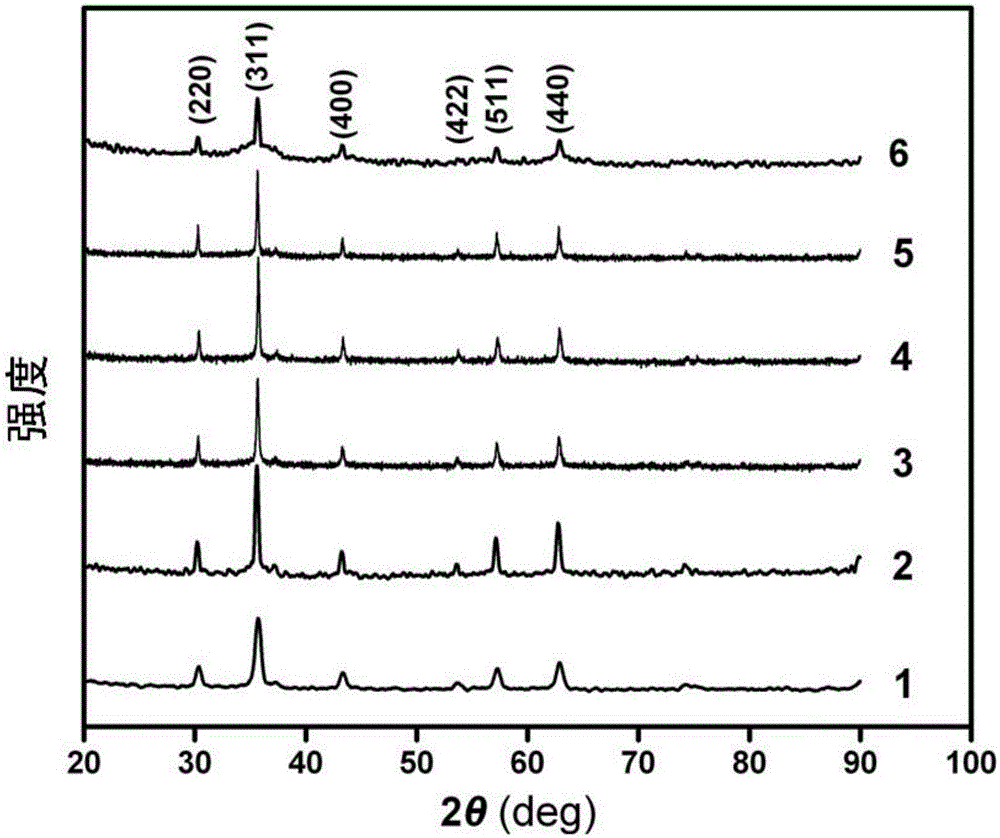

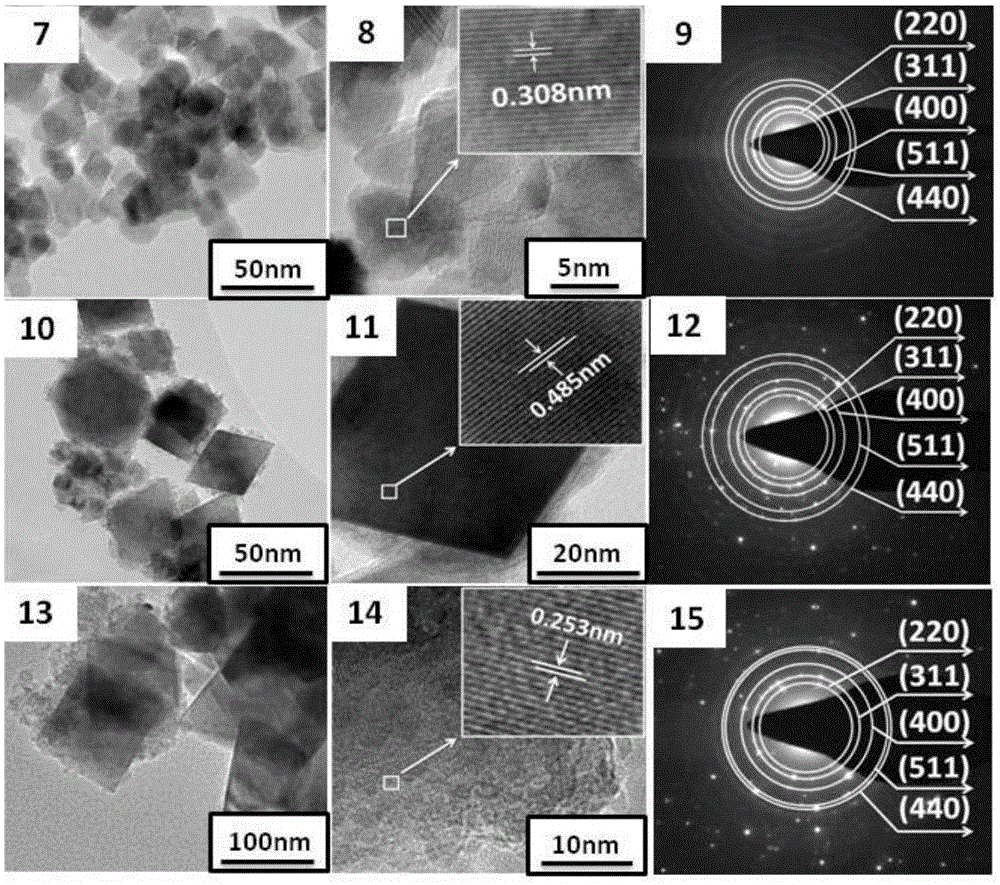

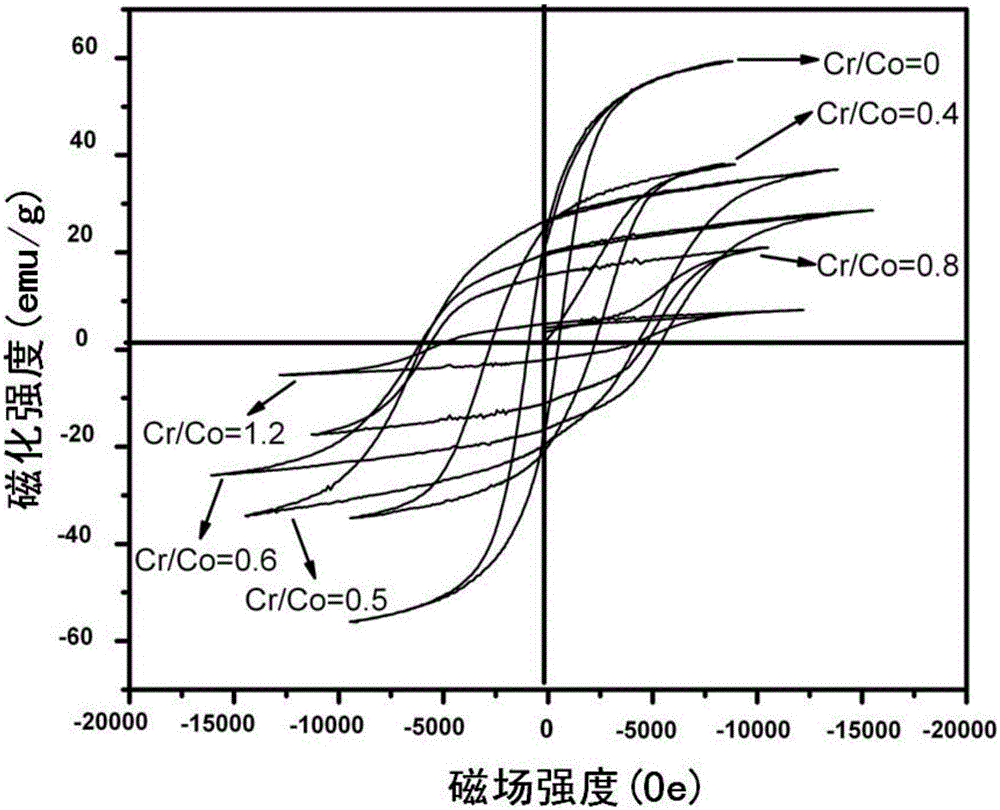

[0021] Step 2: Weigh 0.0055mol of CoCl 2 ·6H 2 O, a certain proportion of CrCl 3 ·6H 2 O, FeCl 3 ·6H 2 O (the total amount of the two substances is 0.011mol, and the molar ratio of each component is Fe / Cr=2:0, 1.6:0.4, 1.5:0.5, 1.4:0.6, 1.2:0.8, 0.8:1.2) fully dissolved In deionized water, a metal salt ion solution is obtained, and the concentration of the metal ion solution is 0.15mol / L-0.25mol / L;

[0022] Step 3, drop the NaOH solution obtained in step 1 into the metal salt ion solution obtained in step 2, and stir for 30 minutes;

[0023] Step 4, pour the mixture obtained in Step 3 into the autoclave and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com