Dicyclopentadiene modified epoxy asphalt mixture and preparation method and uses thereof

A technology of dicyclopentadiene and epoxy asphalt, applied to the preparation of the above dicyclopentadiene modified epoxy asphalt mixture, dicyclopentadiene modified epoxy asphalt mixture, the above dicyclopentadiene modified epoxy asphalt mixture The application field of oxygen asphalt mixture can solve problems such as brittleness, poor impact resistance, poor toughness of epoxy asphalt materials, and reduced service life, so as to increase toughness, improve road performance, and avoid water damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

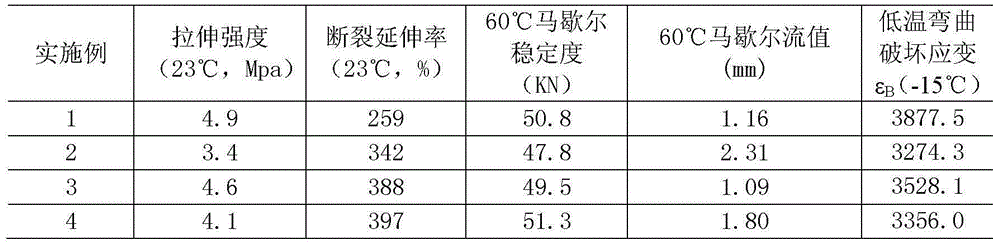

Examples

preparation example Construction

[0049] In the preparation method of the present invention, component A and component B can also be pre-mixed, stirred at 25-60°C, then added to the mineral material and mixed with asphalt at the same time, stirred at 60-150°C to obtain dicyclopentadiene Modified epoxy asphalt mixture.

[0050] The dicyclopentadiene-modified epoxy asphalt material and its mixture described in the present invention can be applied to steel bridge deck, cement concrete bridge deck pavement, pavement and repair of asphalt pavement, and can be used at intersections and parking stations and other special roads.

[0051] The present invention will be described in detail below in conjunction with specific examples. The dicyclopentadiene modified epoxy asphalt mixture adopts AC-13 gradation.

Embodiment 1

[0053] 1) Heat and stir the epoxy resin at 80-120°C until a transparent epoxy resin solution is formed, then add dicyclopentadiene and mix, and stir for 5-10 minutes to obtain component A;

[0054]2) Add 60 parts of polyamide 650 curing agent at 60 degrees to the reaction kettle, add 60 parts of polyazelaic anhydride curing agent, 0.005g of N,N-dimethylaniline accelerator, mix and stir for 20 minutes, and complete component B preparation of

[0055] 3) Mix 100 parts of component A dicyclopentadiene modified epoxy resin with component B, and stir at room temperature for 5 minutes;

[0056] 4) Mix components A and B with 110 parts of 70# petroleum asphalt kept at 120°C for 10 minutes to obtain dicyclopentadiene-modified epoxy asphalt.

[0057] 5) Mix the dicyclopentadiene modified epoxy asphalt into the stone, and stir at 80°C for 60s to obtain the dicyclopentadiene modified epoxy asphalt mixture.

Embodiment 2

[0059] 1) Heat and stir the epoxy resin at 80-120°C until a transparent epoxy resin solution is formed, then add dicyclopentadiene and mix, and stir for 5-10 minutes to obtain component A;

[0060] 2) Add 50 parts of polyamide 650 curing agent with heat preservation at 60 degrees to the reaction kettle, add 75 parts of tung oil modified anhydride curing agent, 0.00625g of N,N-dimethylaniline accelerator, mix and stir for 20 minutes, and complete B component preparation of

[0061] 3) Mix 100 parts of component A dicyclopentadiene modified epoxy resin with component B, and stir at room temperature for 5 minutes;

[0062] 4) Mix the product of step 3 with 112.5 parts of 70# petroleum asphalt kept at 110°C into the stone, and stir at 100°C for 60s to obtain dicyclopentadiene modified epoxy asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com