Manufacturing method for marble-imitated footpath stone and die used therein

A production method, a technology of imitating marble, is applied to the molds used in the production of such imitation marble pavement stones, and the field of production of imitation marble pavement stones, which can solve the problems of cloudy color, high transportation cost, difficult processing, etc., and save time and The effect of materials, ensuring pedestrian safety, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

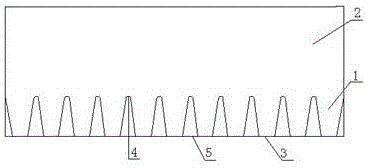

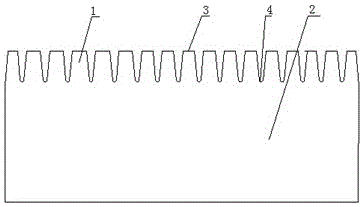

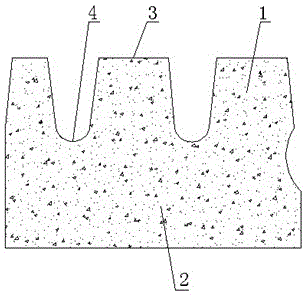

[0034] Combine below figure 1 , figure 2 and image 3 , to describe the specific embodiment of the present invention.

[0035] like figure 1 , image 3 Shown, a kind of manufacture method of imitation marble walkway stone, comprises the manufacture method of walkway stone simulation layer 1 and the manufacture method of walkway stone substrate layer 2, and described walkway stone simulation layer 1 is made by the material that contains following combination: marble Crushed stone, mica crushed stone, river sand, cement, heavy calcium, carbon black, coagulant, clear water, each component by weight percentage is: marble crushed stone 10%-20%, mica stone crushed 5 %-10%, river sand 15%-25%, cement 20%-30%, heavy calcium 2%-4%, carbon black 1%-2%, coagulant 0.5%-1.5%, clear water 25%-35% .

[0036] In the present invention, the matrix layer 2 of imitation marble pavement stone is made by the material that contains following combination: general crushed stone powder, river sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com