A process for producing low-carbon alcohol from syngas combined with coke oven gas

A technology for coke oven gas and low-carbon alcohol, which is applied in the field of synthesizing low-carbon alcohol, and achieves the effects of good thermal stability and chemical stability, adjustment of energy structure, and improvement of enterprise economic benefits and social environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

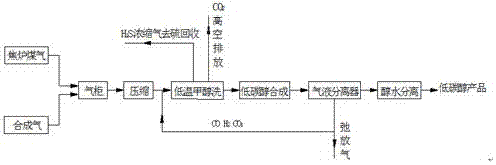

Image

Examples

Embodiment 1

[0029] The coke oven gas (volume percentage is composed of H 2 : 54%, CH 4 : 23%, CO: 10%, CO 2 :7%,N 2 : 6%) and synthesis gas (volume percentage composition is CO: 50%, H 2 : 25%, CO 2 :12,CH 4 : 12%, H 2 S: 0.16%) is passed into the gas cabinet at a volume ratio of 7:1 and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO = 3.5 raw material gas.

[0030] The crude raw material gas is compressed to 4.0MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the pure gas for the synthesis of low-carbon alcohols is produced, and the hydrogen sulfide H removed 2 S desulfurization recovery, CO removal 2 Discharge at high altitude.

[0031]The purified gas enters two fixed-bed low-carbon alcohol reactors connected in series, both of which use modified Cu-Zn-Al-K catalysts from ...

Embodiment 2

[0035] The coke oven gas (volume percentage is composed of H 2 : 60%, CH 4 : 22%, CO: 9%, CO 2 :6%,N 2 : 3%) and synthesis gas (volume percentage composition is CO: 50%, H 2 : 27%, CO 2 : 11%, CH 4 : 12%, H 2 S: 0.20%) is passed into the gas cabinet at a volume ratio of 5:1 and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO = 4.0 raw material gas.

[0036] The crude raw material gas is compressed to 4.5MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the pure gas for the synthesis of low-carbon alcohols is produced, and the hydrogen sulfide H removed 2 S desulfurization recovery, CO removal 2 Discharge at high altitude.

[0037] The purified gas enters two fixed-bed low-carbon alcohol reactors connected in series. The first fixed-bed reactor adopts the Zn-Cr catal...

Embodiment 3

[0041] The coke oven gas (volume percentage is composed of H 2 : 58%, CH 4 : 24%, CO: 8%, CO 2 :6%,N 2 : 4%) and synthesis gas (volume percentage composition is CO: 50%, H 2 : 26%, CO 2 : 11%, CH 4 : 13%, H 2 S: 0.24%) is passed into the gas cabinet at a volume ratio of 3:1 and fully mixed to form a hydrogen-carbon molar ratio that satisfies the synthesis of low-carbon alcohols. 2 / CO = 2.7 raw material gas.

[0042] The crude raw material gas is compressed to 3.8MPa and enters the low-temperature methanol washing and purification device to remove impurities such as hydrogen sulfide and carbon dioxide. 2 S off to less than 0.1ppm, CO 2 Less than 20ppm, the pure gas for the synthesis of low-carbon alcohols is produced, and the hydrogen sulfide H removed 2 S desulfurization recovery, CO removal 2 Discharge at high altitude.

[0043] The purified gas enters three fixed-bed low-carbon alcohol reactors connected in series, and the first fixed-bed reactor adopts MoS from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com