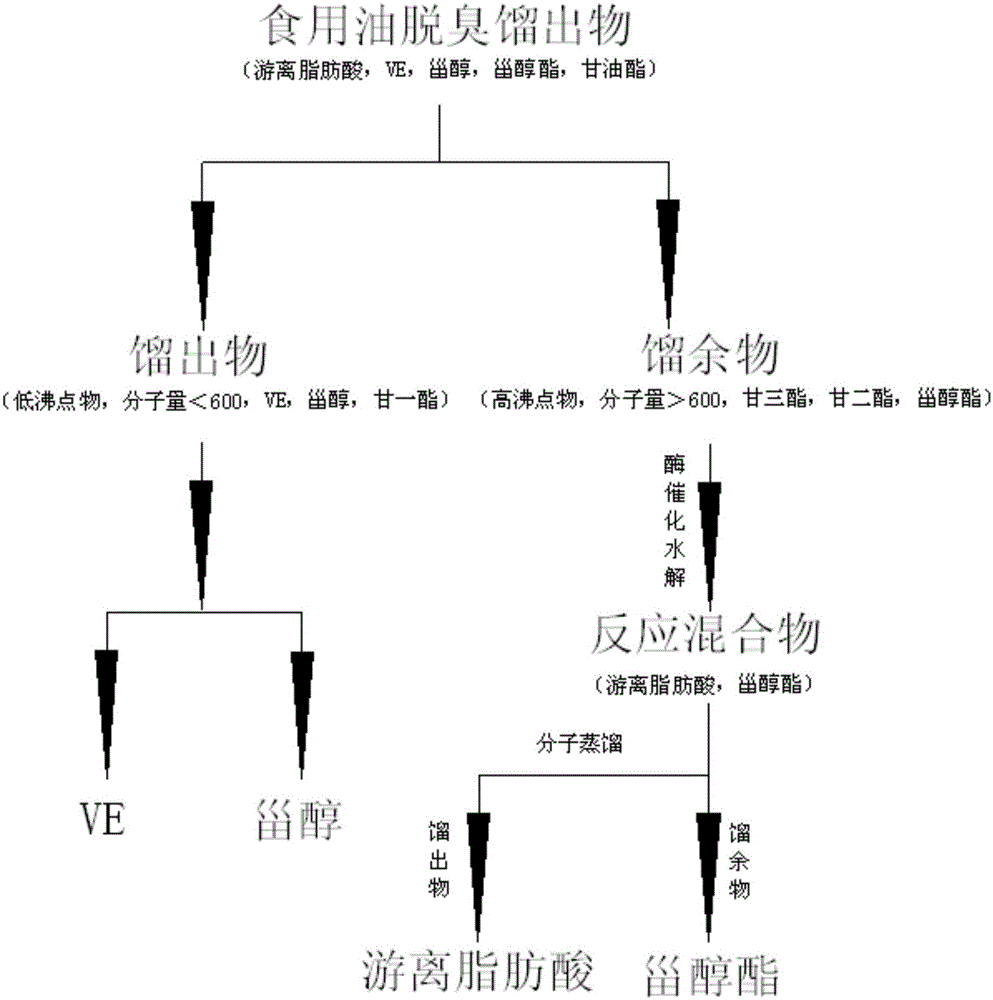

Method of extracting steryl ester from high-temperature deodorized substance of edible oil through combination of enzyme hydrolysis and molecular distillation

A technology of molecular distillation and sterol ester, which is applied in the field of extraction and separation of natural products, can solve the problems of low purity, difficult industrialization of sterol ester, and low yield, and achieve the effects of simple process route, guaranteed edible quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

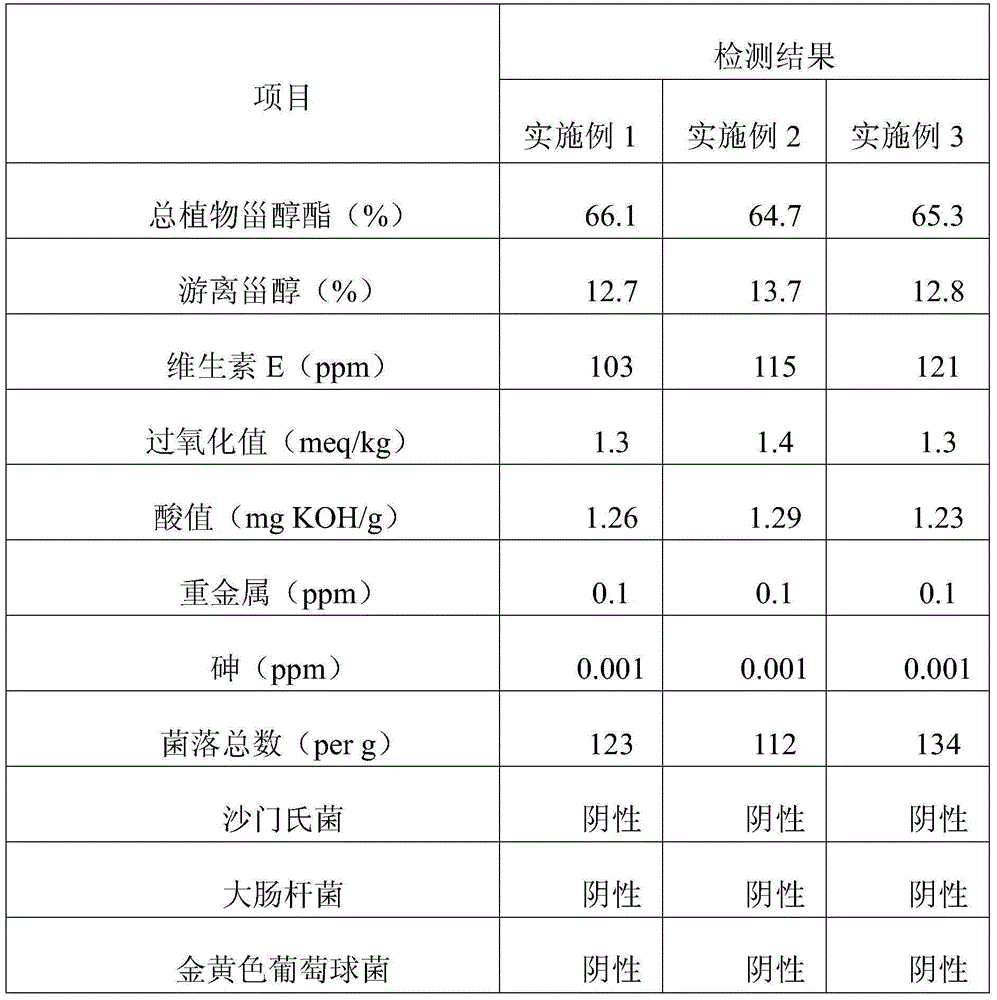

Embodiment 1

[0024] 1) Primary molecular distillation process: using the high-temperature deodorized distillate obtained by the high-low temperature twice fatty acid capture process in the soybean oil refining process as raw material, the low-boiling point substances and high-boiling point substances are separated by molecular distillation, and the distillation in the molecular distillation is controlled. The temperature is 190°C, the vacuum degree is 0.1Pa, the speed of the scraping film is 300r / min, and the flow rate is 2g / min; the low boiling point components are natural vitamin E, free fatty acids, sterols and monoglycerides, and the high boiling point components are triglycerides , diglycerides and sterol esters;

[0025] 2) Enzymolysis process: collect the high boiling point components obtained in step 1), then add water and Novozymes 435 enzyme, by weight fraction, wherein high boiling point components: water: enzyme = 50:150:0.5, in Stir the enzymolysis at 40°C and 200r / min for 8 h...

Embodiment 2

[0028] 1) Primary molecular distillation process: using the high-temperature deodorized distillate obtained by the high-low temperature twice fatty acid capture process in the soybean oil refining process as raw material, separate low-boiling point substances and high-boiling point substances through molecular distillation, and the distillation temperature in molecular distillation The temperature is 230°C, the degree of vacuum is 20Pa, the rotating speed of the scraping film is 600r / min, and the flow rate is 5g / min; the low boiling point components are natural vitamin E, free fatty acids, sterols and monoglycerides, and the high boiling point components are triglycerides, glycerol Diesters and sterol esters;

[0029] 2) Enzymolysis process: collect the high boiling point components obtained in step 1), then add water and Novozymes 435 enzyme, by weight fraction, wherein high boiling point components: water: enzyme = 150:50:5, in Stir the enzymolysis at 80°C and 400r / min for 2...

Embodiment 3

[0032] 1) Primary molecular distillation process: using the high-temperature deodorized distillate obtained by the high-low temperature twice fatty acid capture process in the soybean oil refining process as raw material, separate low-boiling point substances and high-boiling point substances through molecular distillation, and the distillation temperature in molecular distillation The temperature is 210°C, the vacuum degree is 1Pa, the speed of scraping film is 450r / min, and the flow rate is 3.7g / min; the low boiling point components are natural vitamin E, free fatty acids, sterols and monoglycerides, and the high boiling point components are triglycerides, diglycerides and sterol esters;

[0033] 2) Enzymolysis process: collect the high boiling point components obtained in step 1), then add water and Novozymes 435 enzyme, by weight fraction, wherein high boiling point components: water: enzyme = 50:50:1, in Stir the enzymolysis at 60°C and 300r / min for 16 hours; after the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com